Metal additive manufacturing has transitioned from prototyping to production for many industries, such as aerospace, medical, tooling, and automotive. Selecting the right metal for a 3D printing job requires balancing mechanical requirements, thermal exposure, cost, and downstream processing. In this article, we examine the top five metals most commonly used in 3D printing, including aluminum, stainless steel, titanium, tool steel, and Inconel.

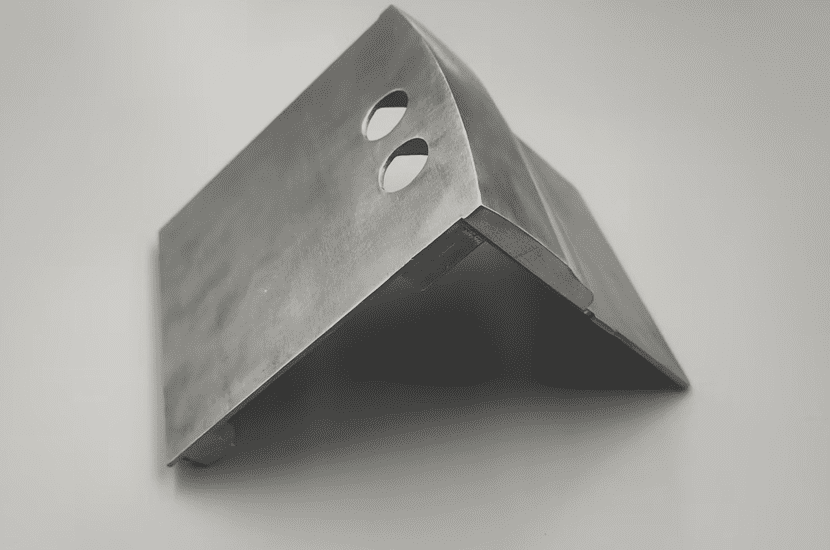

Aluminum

Why It’s Used

Aluminum alloys, and specifically AlSi10Mg in powder-bed fusion (PBF) systems, offer an excellent strength-to-weight ratio, good thermal conductivity, and relatively low density. That combination makes aluminum ideal for lightweight structural components and thermal management parts.

Key Properties

• Thermal conductivity: High, enabling efficient heat dissipation

• Corrosion resistance: Naturally forms a protective oxide layer

• trength: Moderate, but can be enhanced with alloying

Applications

• Aerospace brackets, housings, and ducting.

• Automotive lightweighting components.

• Consumer electronics casings where thermal conductivity is critical.

Advantages

• Excellent for lightweight structures where reducing mass is critical (aerospace, automotive).

• Good thermal management properties, making it suitable for heat exchangers and housings.

• Readily available powders optimized for laser powder bed fusion (LPBF) processes.

Limitations

• Lower absolute strength compared to titanium or steel.

• Susceptible to hot cracking during solidification if not carefully controlled.

• Surface finish often requires post-processing for functional parts.

Engineering Considerations

Aluminum powders are prone to balling and spatter in LPBF if parameters aren’t optimized. Build orientation affects residual stresses and surface finish. Post-process solution annealing and aging (T6-like) or hot isostatic pressing (HIP) reduce porosity and improve ductility. Design for manufacturability should minimize thin unsupported overhangs and account for 3D printing anisotropy in fatigue-critical components.

3DSPRO Aluminum 3D Printing Service >>

Image Copyright © 3DSPRO Limited. All rights reserved.

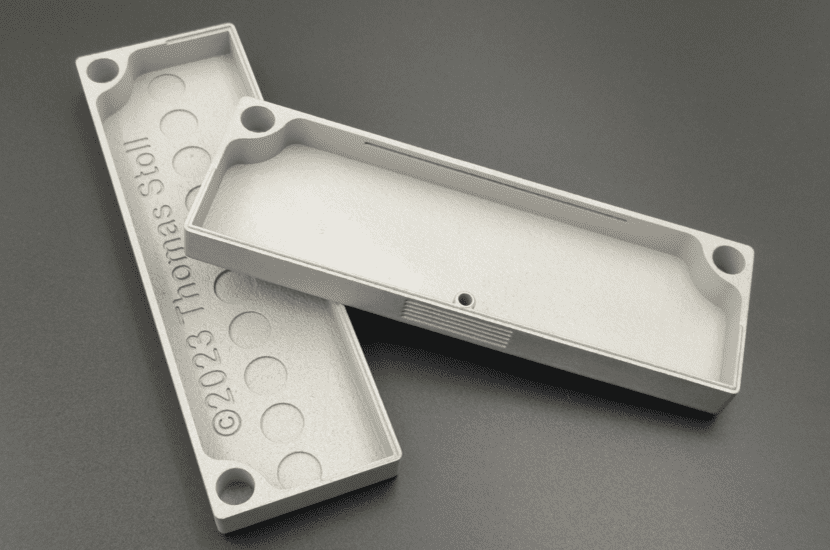

Stainless Steel

Why It’s Used

Stainless steels combine corrosion resistance and good mechanical properties at a competitive material cost. 316L is the most common stainless powder for 3D printing due to its toughness and corrosion resistance; 17-4 PH is selected when higher strength and moderate corrosion resistance are required.

Key Properties

• Corrosion resistance: Excellent, especially in grades like 316L

• Strength: High tensile strength with good toughness

• Weldability: Well-suited for 3D printing processes

Applications

• Medical implants and surgical instruments.

• Food processing equipment and chemical handling components.

• Industrial tooling, jigs, and fixtures.

Advantages

• Affordable and accessible, making it a common entry point for metal 3D printing.

• High ductility and toughness, even at cryogenic temperatures.

• Biocompatibility of certain grades (e.g., 316L) makes them suitable for medical implants.

Limitations

• Heavier than aluminum or titanium, limiting use in weight-sensitive applications.

• Thermal conductivity is lower than aluminum, restricting heat management roles.

• Requires careful post-processing to achieve optimal surface finish.

Engineering Considerations

Stainless powders oxidize less readily than reactive metals but still require controlled atmosphere processing. 17-4 PH requires precipitation hardening to reach nominal strength; 316L often benefits from solution annealing or HIP for improved fatigue life. Surface roughness from LPBF can accelerate corrosion in crevices, final machining, passivation, or electropolishing are common.

3DSPRO Stainless Steel 3D Printing Service >>

Image Copyright © 3DSPRO Limited. All rights reserved.

Titanium

Why It's Used

Titanium alloys provide an exceptional strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, making them the top choice for aerospace, medical implants, and high-performance structures where weight savings are critical.

Key Properties

• Strength: Comparable to high-strength steels

• Corrosion resistance: Excellent, even in harsh environments

• Biocompatibility: Non-toxic and well-tolerated by the human body

Applications

• Aerospace structural components, turbine blades, and brackets.

• Medical implants such as hip cups, spinal cages, and dental fixtures.

• High-performance automotive and motorsport parts.

Advantages

• Superior strength-to-weight ratio, ideal for aerospace and medical applications.

• Corrosion resistance extends service life in marine and chemical environments.

• Biocompatibility makes it the material of choice for orthopedic and dental implants.

Limitations

• High cost of raw powder and processing.

• Reactive nature requires inert gas shielding during printing.

• Post-processing (heat treatment, machining) is often necessary to achieve final properties.

Engineering Considerations

Titanium powders are reactive and require strict powder handling and inert atmospheres (argon). 3D printed Ti-6Al-4V commonly exhibits microstructural anisotropy (columnar grains) that affects fatigue performance. Designers must account for build orientation and may require HIP and stress-relief annealing. Surface finishing and machining are often needed for bearing surfaces or threaded connections.

3DSPRO Titanium 3D Printing Service >>

Power Coated Ti64 Box:

Image Copyright © 3DSPRO Limited. All rights reserved.

Tool Steel

Why It's Used

Tool steels and maraging steels are chosen for high-strength, wear-resistant, and heat-resistant tooling and dies produced via 3D printing. Maraging steels combine high strength with good toughness after aging; H13 and other hot-work tool steels are used when thermal fatigue resistance is necessary.

Key Properties

• Hardness: High, especially after heat treatment

• Wear resistance: Excellent, suitable for high-load applications

• Toughness: Varies by grade (e.g., H13, maraging steels)

Applications

• Injection molding inserts with conformal cooling.

• Cutting tools, dies, and punches.

• Industrial wear parts and fixtures.

Advantages

• Enables rapid tooling, such as injection molds, dies, and cutting tools, can be produced directly.

• Complex cooling channels can be integrated into molds, improving cycle times.

• High hardness and wear resistance extend tool life.

Limitations

• Brittle compared to stainless steels.

• Requires post-print heat treatment to achieve full hardness.

• Limited use in lightweight applications due to density.

Engineering Considerations

Tool steels often need careful thermal cycles (preheating, controlled cooling) during post-processing to avoid cracking. For high-load tools, stress-relief, solution treatments, and aging are standard. Tool steels can be abrasive to cutting tools during post-machining.

3DSPRO Maraging Steel 3D Printing Service >>

Image Copyright © 3DSPRO Limited. All rights reserved.

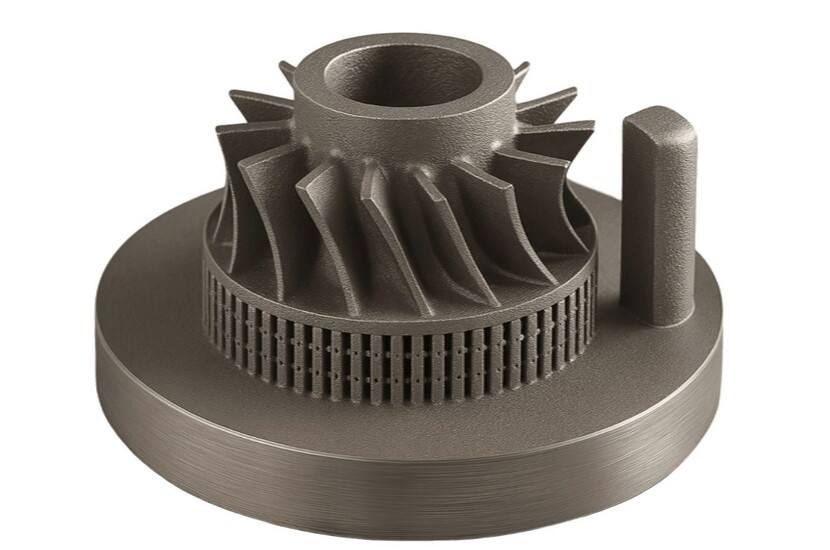

Inconel

Why It’s Used

Inconel nickel-based superalloys provide outstanding high-temperature strength, oxidation, and corrosion resistance, which is essential for gas turbines, rocket engines, and exhaust systems.

Key Properties

• High-temperature strength: Retains mechanical properties above 700°C

• Corrosion resistance: Excellent in oxidizing and reducing environments

• Creep resistance: Outstanding under sustained loads at elevated temperatures

Applications

• Jet engine turbine blades and combustor components.

• Gas turbine parts for power generation.

• Chemical processing equipment exposed to corrosive media.

Advantages

• Superior high-temperature performance, ideal for aerospace and energy sectors.

• Corrosion resistance in aggressive chemical environments.

• 3D printing enables complex cooling geometries in turbine and combustion components.

Limitations

• High cost of raw material and processing.

• Difficult to machine.

• High density limits use in weight-sensitive designs.

Engineering Considerations

These alloys exhibit significant residual stresses during 3D Printing and often require stress-relief and solution/aging treatments. Build orientation and support design are critical to avoid warping. Inconel powders are expensive; nesting multiple small parts in a single build or using topology optimization to reduce mass can improve cost-efficiency.

3DSPRO Inconel 3D Printing Service >>

Image Copyright © 3DSPRO Limited. All rights reserved.

3DSPRO Metal 3D Printing Services

Metal 3D Printing Capabilities at 3DSPRO:

• Material Portfolio: Aluminum, stainless steel, titanium, tool steel, Inconel, and more.

• Processes Supported: Laser Powder Bed Fusion (LPBF).

• Engineering Support: Design consultation, topology optimization, and simulation-driven validation.

• Customization: Tailored solutions for lightweighting, thermal management, and high-performance applications.

• Industry Compliance: Parts manufactured to aerospace, medical, and industrial standards.

• Post-processing: Heat treatment, HIP (Hot Isostatic Pressing), CNC machining, and surface finishing.

• Scalability: From rapid prototyping to full-scale production runs.

COMMENTS

- Be the first to share your thoughts!