Metal additive manufacturing (AM) has rapidly gained traction across industries—from automotive and aerospace to medical and tooling. Yet, one common question prevails: How much does metal 3D printing cost? Unlike plastic 3D printing, metal AM involves expensive powders, advanced machines, and post-processing steps that all contribute to the final price. Understanding these components of Metal 3D Printing Cost lets you manage expectations, compare suppliers effectively, and optimize your designs for affordability.

Key Factors Influencing Metal 3D Printing Cost

1. Material Costs

Metal powders—such as stainless steel, titanium, aluminum, and nickel alloys—are priced per kilogram and fluctuate based on market demand. For instance, stainless steel powder might be around $50–$60/kg, whereas titanium can exceed $300/kg. Moreover, powder reuse, recycling rates, and scrap from support structures add complexity. High-demand alloys or specialty grades (e.g., maraging steel for aerospace) command premium prices.

2. Machine and Technology Selection

Different processes carry different price tags. SLM/DMLS machines typically run $150–$300 per machine hour, factoring in laser operation, gas consumption, and maintenance. Electron Beam Melting (EBM) machines may have higher hourly costs due to vacuum requirements, whereas Directed Energy Deposition (DED) systems vary based on wire or powder feed. Your choice of technology directly influences the Metal 3D Printing Cost—for example, fine-powder DMLS will be costlier than Binder Jetting, followed by sintering.

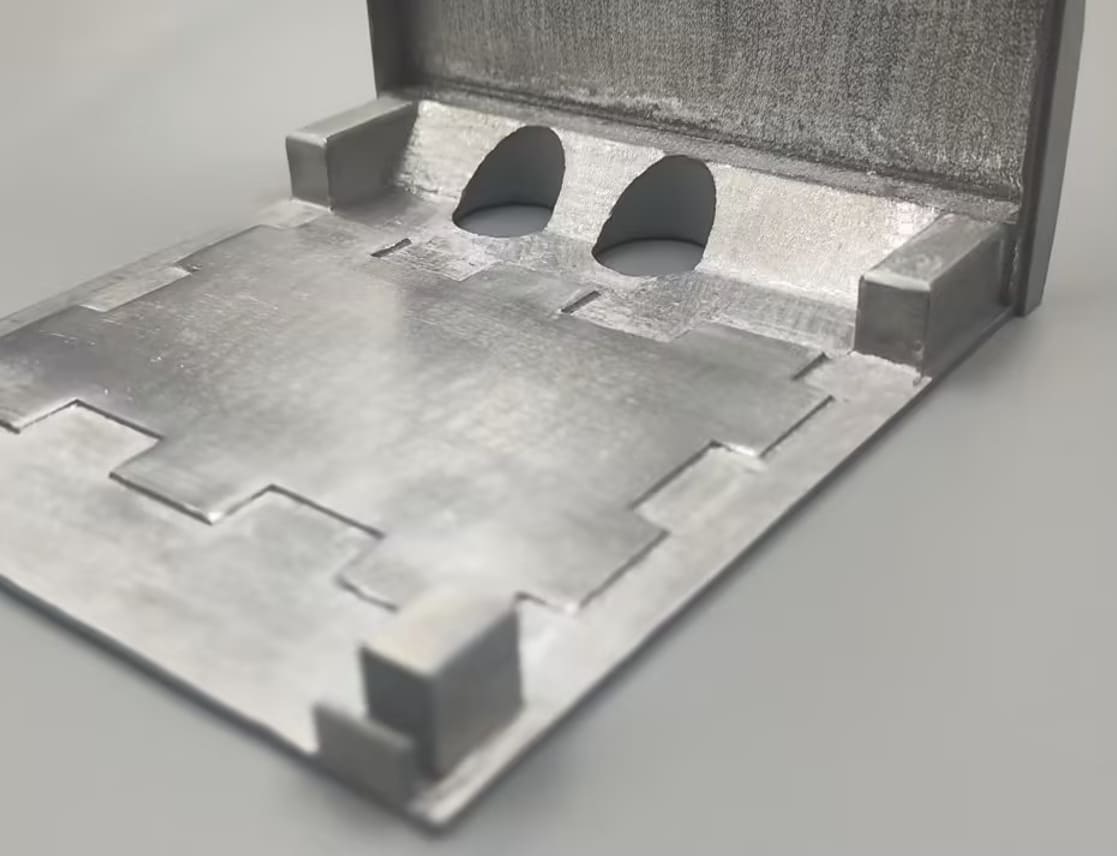

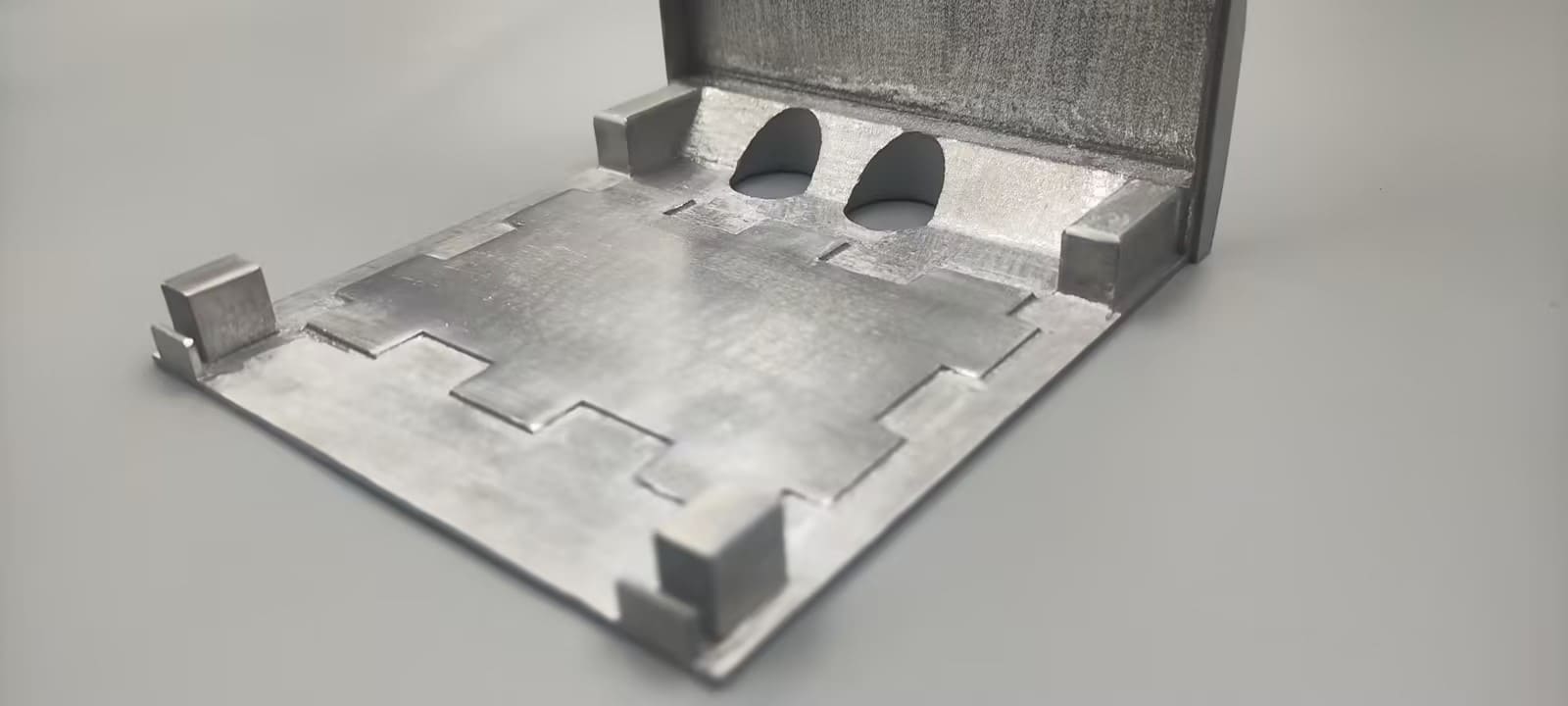

3. Part Complexity and Geometry

Intricate designs with overhangs, internal channels, or lattice structures often require additional supports, increasing build time and post-processing labor. Complex geometries demand slower scan patterns, finer layer thicknesses, and more careful heat management. Build orientation matters too: orienting a part to minimize supports can reduce material usage and machine time, directly lowering cost.

4. Build Volume and Production Volume

Printing multiple parts in a single build can improve machine utilization and drive down metal 3D printing cost per unit. Small prototypes may incur a higher per-part cost than medium or large batches because the machine still consumes a fixed amount of energy and labor. However, extremely large builds may require different machines or even give up fine details, affecting cost versus quality trade-offs.

5. Post-Processing Requirements

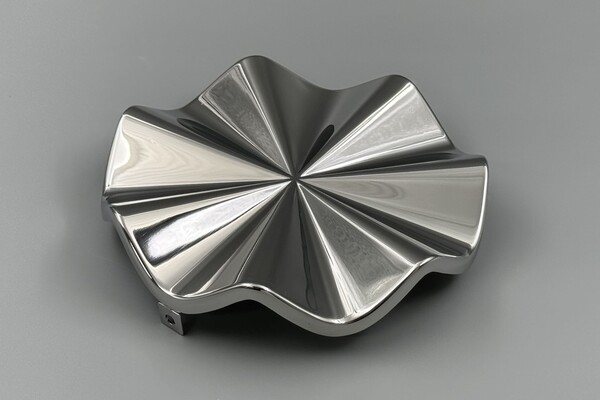

After printing, most metal parts need heat treatment (like HIP—Hot Isostatic Pressing) to reduce internal porosity, as well as surface finishing (CNC machining, polishing, bead blasting, or shot peening). Inspection steps—such as CT scanning or CMM (coordinate measuring machine) audit—add to labor and equipment charges. Each post-processing step adds 10–40% to the base build cost, depending on part complexity and tolerances.

6. Labor and Overhead

Operating metal AM machines demands skilled technicians. Setup, monitoring, powder handling, and post-processing all require labor hours. Facility overhead—electricity, maintenance, rent, and machine depreciation—also factors into service bureau pricing. At 3DSPRO, our experienced technicians and streamlined workflow help keep overhead efficient, but it’s important to recognize that labor is a sizable component of Metal 3D Printing Cost.

Cost Breakdown: Understanding Your Quote

1. Material Cost per Part

Material usage is calculated by the part’s volume multiplied by the powder density plus allowances for supports and potential recycling losses. For example, if your part’s net volume consumes 0.5 kg of stainless steel but supports add 0.1 kg, and recycling yields 90% reuse, your net material cost might be:

(0.5 kg + 0.1 kg) × $60/kg × (1 – 0.10) = $32.40

2. Machine Hourly Rate and Build Time

Build time depends on part volume, layer thickness (commonly 20–50 µm for fine detail), and machine speed. If a DMLS machine runs $200/hour, and your part takes 6 hours to build, the machine cost equals $1,200. Multiple parts nested in one build can share this hourly expense, lowering per-unit cost.

3. Post-Processing Fees

Post-processing tasks include heat treatment (e.g., $50–$100 per batch), HIP ($100–$300 depending on part size), machining ($50–$150/hour of CNC work), and surface finishes ($20–$100 per hour). For a single aerospace bracket requiring HIP and CNC finishing, post-processing alone might add $200–$400.

4. Labor Costs

Technician labor for unpacking, depowdering, inspection, and packing is typically billed per hour—around $40–$80/hour. Simple visual inspections cost less, but full CMM audits can take 1–2 hours. Complex assemblies requiring welding, assembly, or custom fixturing increase labor hours.

5. Overhead and Profit Margin

Service bureaus include overhead—facility utilities, machine depreciation, software licensing, and administrative costs—plus a profit margin (often 15–30%). When comparing quotes from different bureaus, look beyond the bottom-line number: check for transparent breakdowns of material, machine, post-processing, and labor.

Comparing Metal 3D Printing Technologies and Their Costs

|

Technology |

Hourly Rate (≈) |

Material Options |

Build Speed & Volume |

Post-Processing Needs |

Cost Considerations |

|

$150–$300/hour |

Ti-6Al-4V, Inconel, Al alloys, steels |

Fine layers (20–50 µm) → slower but precise; moderate build volume |

HIP (±$100–$300), CNC finishing ($50–$150/hr) |

• High‐precision parts → higher machine time |

|

|

DMLS (Direct Metal Laser Sintering) |

$150–$300/hour |

Maraging steels, stainless steel, Inconel, cobalt‐chrome |

Similar layer thickness to SLM; slightly faster for some alloys |

Heat treat ($50–$100), surface finish ($20–$100/hr) |

• Thicker layers (30–50 µm) possible → marginally faster builds |

|

EBM (Electron Beam Melting) |

$250–$400/hour |

Primarily Ti alloys (Ti-6Al-4V, Ti-6Al-4V ELI) |

Faster for large Ti parts; operates under vacuum → larger build envelopes |

HIP (often included), minimal supports; machining ($50–$150/hr) |

• High machine overhead (vacuum, maintenance) |

|

$100–$200/hour |

Stainless steel, tool steels, some superalloys |

Fast build speed; larger build volumes; layers ~50–100 µm |

Debinding & sintering furnace ($30–$60 per cycle), shrinkage control |

• Lower upfront machine cost |

|

|

DED (Directed Energy Deposition) |

$200–$350/hour |

Wire or powder: Ti, Ni, Co, steel alloys |

Coarser resolution; best for large structures or repairs |

CNC machining often required ($50–$150/hr); heat treat ($50–$100) |

• Higher powder/wire feed costs |

Tips to Reduce Your Metal 3D Printing Cost

1. Design Optimization for Cost Efficiency

• Lightweighting with Lattices: Replacing solid infill with lattice structures reduces material and build time without sacrificing strength.

• Self-Supporting Orientations: Orient parts so overhangs ≤ 45° eliminate extra supports.

• Avoid Over-Engineering: Remove unnecessary fillets, thick walls, or overly tight radii that increase laser passes and post-processing.

By sharing your CAD files with 3DSPRO’s engineering team, we can suggest orientation and support optimizations to trim costs.

2. Batch Printing and Nesting Parts

Group multiple small parts into a single build to share machine setup and hourly fees. However, ensure parts are spaced to allow proper heat dissipation and powder flow. Our quoting portal shows recommended nesting layouts, and estimates cost savings when clustered.

3. Material Selection Strategies

If your application allows, opting for a lower-cost alloy—such as 17-4 PH stainless steel instead of Ti-6Al-4V titanium—can save 40–60% on powder costs. Recycling powder can reduce material expenses, but too many reuse cycles may degrade powder quality, affecting mechanical properties. At 3DSPRO, we maintain strict powder-handling certifications to balance cost savings with material integrity. (3D printing metals comparison at 3DSPRO)

4. Partnering with the Right Service Bureau

Long-term partnerships often unlock volume discounts. Negotiating multi-part or quarterly contracts can lower your Metal 3D Printing Cost by 10–20%. Verify that your provider holds relevant certifications to avoid costly rework or part rejections later.

5. Streamlining Post-Processing

Consolidate finishing steps—e.g., combining heat treatment with HIP cycles—to reduce separate furnace runs. If your surface finish tolerance is looser (e.g., Ra 2.5 µm instead of Ra 1.6 µm), skip costly precision machining. 3DSPRO’s in-house full-spectrum post-processing (heat treating, machining, surface finishing) lets you bundle services and save on shipping and handling fees.

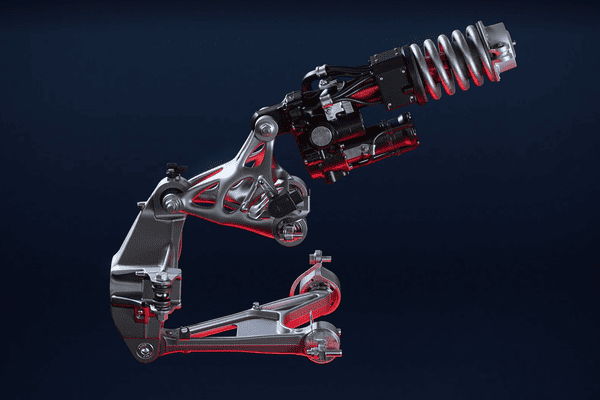

Return on Investment (ROI) and Value of Metal 3D Printing

Cost vs. Performance Trade-Off

High initial costs for metal 3D printing are offset by design advantages—complex internal channels for conformal cooling in molds, lightweight lattice structures for aerospace brackets, and integrated assemblies that eliminate welding or bolting. An optimized bracket printed in titanium might cost $500 per unit but reduce weight by 60%, improving fuel efficiency and lowering operational expenses over the aircraft’s service life.

Long-Term Savings and Competitive Advantage

Faster design iterations mean quicker prototyping: instead of waiting weeks for tooling, metal AM can produce prototypes in days. Shorter lead times accelerate product launches, translating into earlier revenue. On-demand spare parts reduce inventory carrying costs—airlines, for instance, retain fewer spare turbine blades because they can be printed as needed.

Partnering with 3DSPRO leverages our engineering support—design-for-AM reviews, material consultations, and post-processing integration—to ensure your parts deliver maximum performance at the best Metal 3D Printing Cost. Our goal is to be your strategic AM partner >>

COMMENTS

- Be the first to share your thoughts!