The Importance of Post-processing for SLS 3D Prints

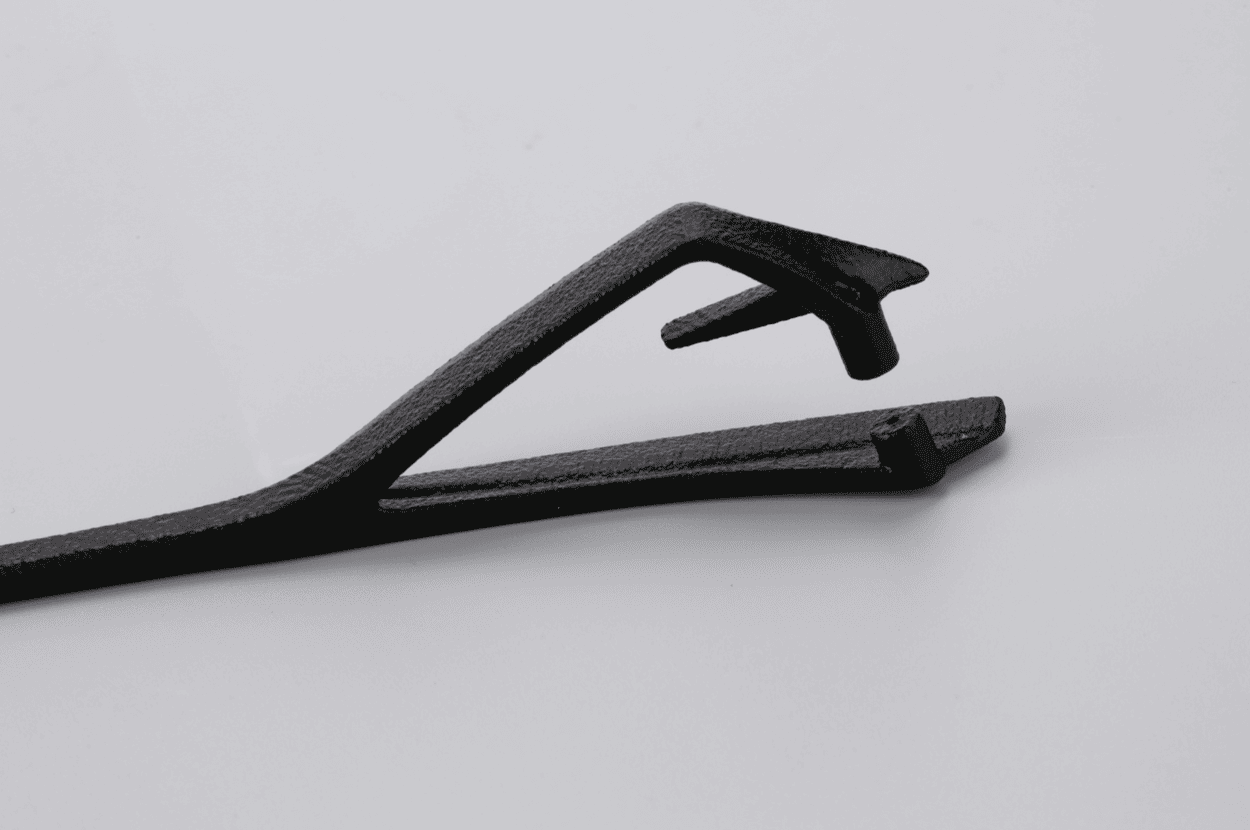

Selective Laser Sintering (SLS) is one of the most versatile additive manufacturing technologies, producing strong, functional parts directly from powder. However, raw SLS prints typically emerge with a matte, porous surface and a slightly grainy texture. While this is acceptable for prototypes or internal components, most end-use applications demand higher-quality finishes.

Post-processing transforms these raw prints into professional-grade products by:

• Improving Aesthetics: adding color, gloss, or smoothness for consumer appeal.

• Enhancing Functionality: sealing pores, reducing friction, or improving wear resistance.

• Increasing Durability: protecting against UV, moisture, or chemical exposure.

• Elevating User Experience: creating parts that look and feel like finished product

Dyeing

Process

SLS parts are immersed in heated dye baths, allowing pigments to penetrate the porous nylon surface.

Applications

Consumer goods, wearables, and functional prototypes where consistent, durable color is essential.

Advantages

• Deep, uniform coloration that resists scratches.

• Maintains flexibility and mechanical properties.

• Cost-effective and scalable for batches.

Limitations

• Best suited for darker or saturated colors.

• UV stability may require additional coatings.

Engineer’s Note

When dyeing SLS parts, surface preparation is minimal, but consistency in bath temperature and immersion time is critical. Engineers often run small test pieces first to calibrate color depth, since nylon’s porosity can vary slightly between builds. For long-term outdoor use, consider pairing dyeing with a UV-resistant clear coat to prevent fading.

Image Copyright © 3DSPRO Limited. All rights reserved.

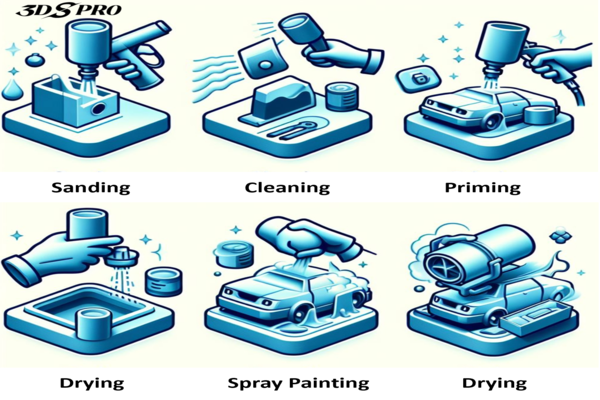

Spray Painting

Process

Parts are primed, painted, and sealed with protective coatings.

Applications

Display models, marketing samples, and low-wear consumer products.

Advantages

• Unlimited color palette, including metallics and custom branding.

• Wide range of finishes: matte, satin, or glossy.

• Ideal for parts requiring visual impact.

Limitations

• Requires careful surface preparation.

• Paint may chip or wear under heavy use.

Engineer’s Note

Always sand or bead-blast SLS parts before priming to ensure paint adhesion. A high-build primer can help fill the natural grain of SLS surfaces, reducing the number of paint layers required. For functional prototypes, engineers recommend a polyurethane topcoat for added durability without significantly increasing thickness.

Image Copyright © 3DSPRO Limited. All rights reserved.

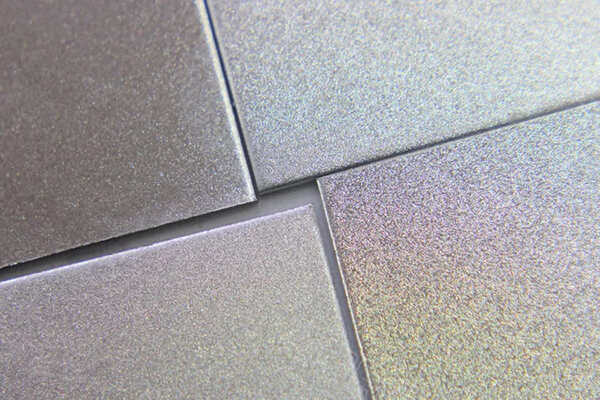

Vapor Smoothing

Process

Parts are exposed to controlled chemical vapors that slightly melt and reflow the outer surface, sealing pores and creating a glossy finish.

Applications

Medical devices, fluid-handling components, and consumer products require a polished look and functional sealing.

Advantages

• Smooth, sealed surfaces with reduced porosity.

• Improved mechanical properties and resistance to moisture.

• Professional, injection-molded appearance.

Limitations

• Requires specialized equipment and safety protocols.

• Slight dimensional changes may occur.

Engineer’s Note

Dimensional accuracy can shift slightly during vapor smoothing, so avoid applying this process to parts with tight tolerances unless compensated in the CAD model. Engineers typically mask critical interfaces or mating surfaces before smoothing. This method also improves chemical resistance, making it valuable for parts exposed to oils or solvents.

Image Copyright © 3DSPRO Limited. All rights reserved.

Vibratory Smoothing

Process

Parts are placed in vibratory or tumbling machines with abrasive media that gradually polish the surface.

Applications

End-use parts, functional prototypes, and components requiring a professional tactile finish.

Advantages

• Consistent, tactile smoothness across batches.

• Scalable for medium-to-large production runs.

• Enhances the tactile and usability of parts.

Limitations

• May soften sharp edges or fine details.

• Not suitable for delicate geometries.

Engineer’s Note

Media selection is key: ceramic media provides aggressive smoothing but may round edges, while plastic or organic media offer gentler polishing. Engineers often run multi-stage cycles, starting with coarse media and finishing with fine polishing agents. For thin-walled parts, lower vibration intensity prevents deformation or cracking. Large parts may not be suitable for vibratory smoothing due to chamber size limitations.

Comparing the Four Methods

|

Method |

Finish Quality |

Durability |

Color Options |

Cost |

Best For |

|

Dyeing |

Matte, uniform |

High |

Limited |

Low |

Functional colored parts |

|

Spray Painting |

Matte/Glossy |

Medium |

Unlimited |

Medium |

Aesthetic prototypes |

|

Vapor Smoothing |

Glossy, sealed |

High |

N/A |

High |

Sealed, smooth surfaces |

|

Vibratory Smoothing |

Satin, tactile |

High |

N/A |

Medium |

Batch smoothing |

Select 3DSPRO’s 3D Plus™ Services

At 3DSPRO, we understand that a 3D print is only as good as its finish. That’s why our 3D Plus™ Services go beyond printing to deliver production-ready results.

With 3D Plus™, you gain:

• Expert Finishing Options: dyeing, spray painting, vapor smoothing, and vibratory smoothing. All tailored to your application.

• Scalable Solutions: from single prototypes to full production runs.

• Consistent Quality: every part meets professional standards for look, feel, and performance.

• End-to-End Support: from design consultation to final delivery.

Whether you need a vibrant prototype for a product launch, a sealed component for fluid handling, or a batch of consumer-ready parts, 3DSPRO’s 3D Plus™ Services ensure your SLS prints stand out for all the right reasons.

COMMENTS

- Be the first to share your thoughts!