How to get a special surface finish for clear resin 3D prints?

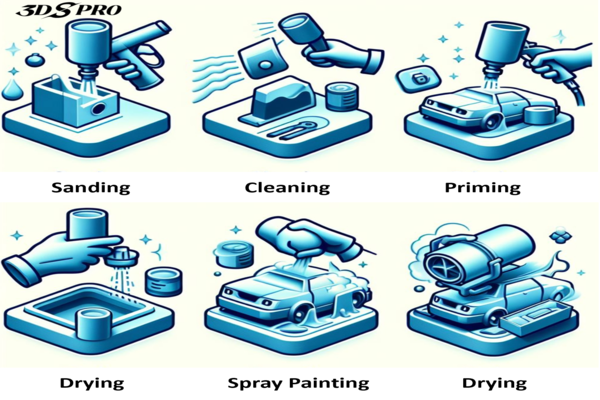

Common post-processing methods for resin 3D prints, such as painting, coating, dyeing, sanding, and electroplating, are also applicable to clear resin prints. However, are there any special surface finishing methods that are suitable for clear resin?

Specific effects can be transparency, translucency, and frosting, and these effects often require more specialized techniques.

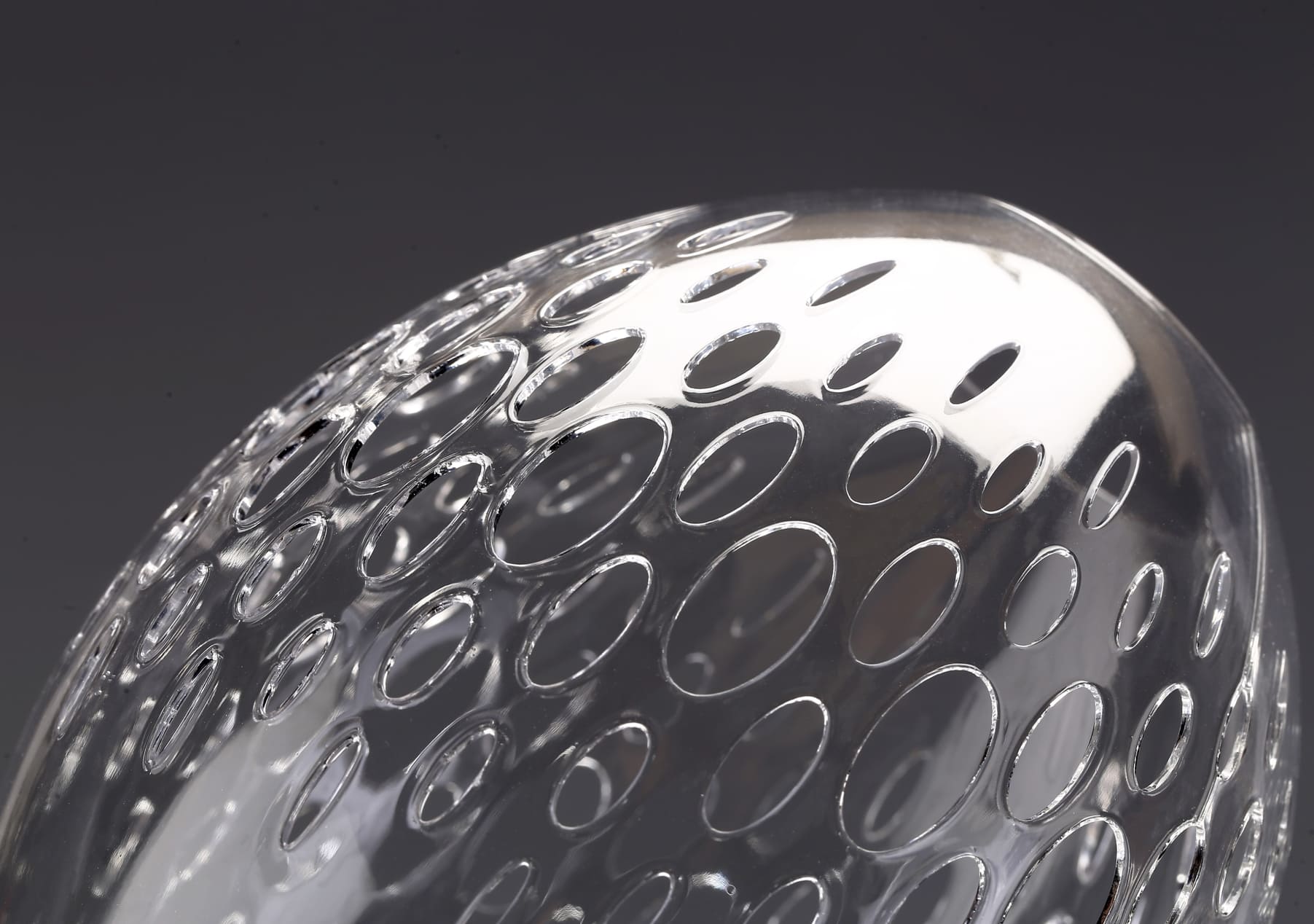

To achieve the transparency effect, methods such as smooth sanding and UV varnishing effectively enhance clarity by filling in surface imperfections and creating a smooth, glass-like finish.

To achieve the translucent effect, controlled nitrogen UV curing can be used to fine-tune the surface and microstructure to allow light to pass through while maintaining a certain diffusion.

To achieve the frosted effect, applying a clear protective spray and using a specific sanding technique can create a diffuse matte surface that scatters light, giving the print an elegant frosted look.

Such advanced finishing techniques enable clear resin prints to meet a wide range of aesthetic and functional needs.

Transparency

Transparency in 3D printing refers to clear resin parts that have been post-processed to allow light to pass through with minimal scattering or absorption, resulting in a clear, transparent object. Transparency is highly recommended for use in optical applications such as lenses and display covers.

Key Features of Transparency:

1. Transparent resin 3D printing has minimal haze and a clear appearance, allowing objects behind it to be seen with high fidelity.

2. They have a high level of light transmittance, making them ideal for applications such as lenses and light guides.

3. Transparency reduces surface roughness and enhances the optical properties of the print.

4. The clear resin formula used is low in impurities and additives, and the materials used are critical to producing truly clear parts.

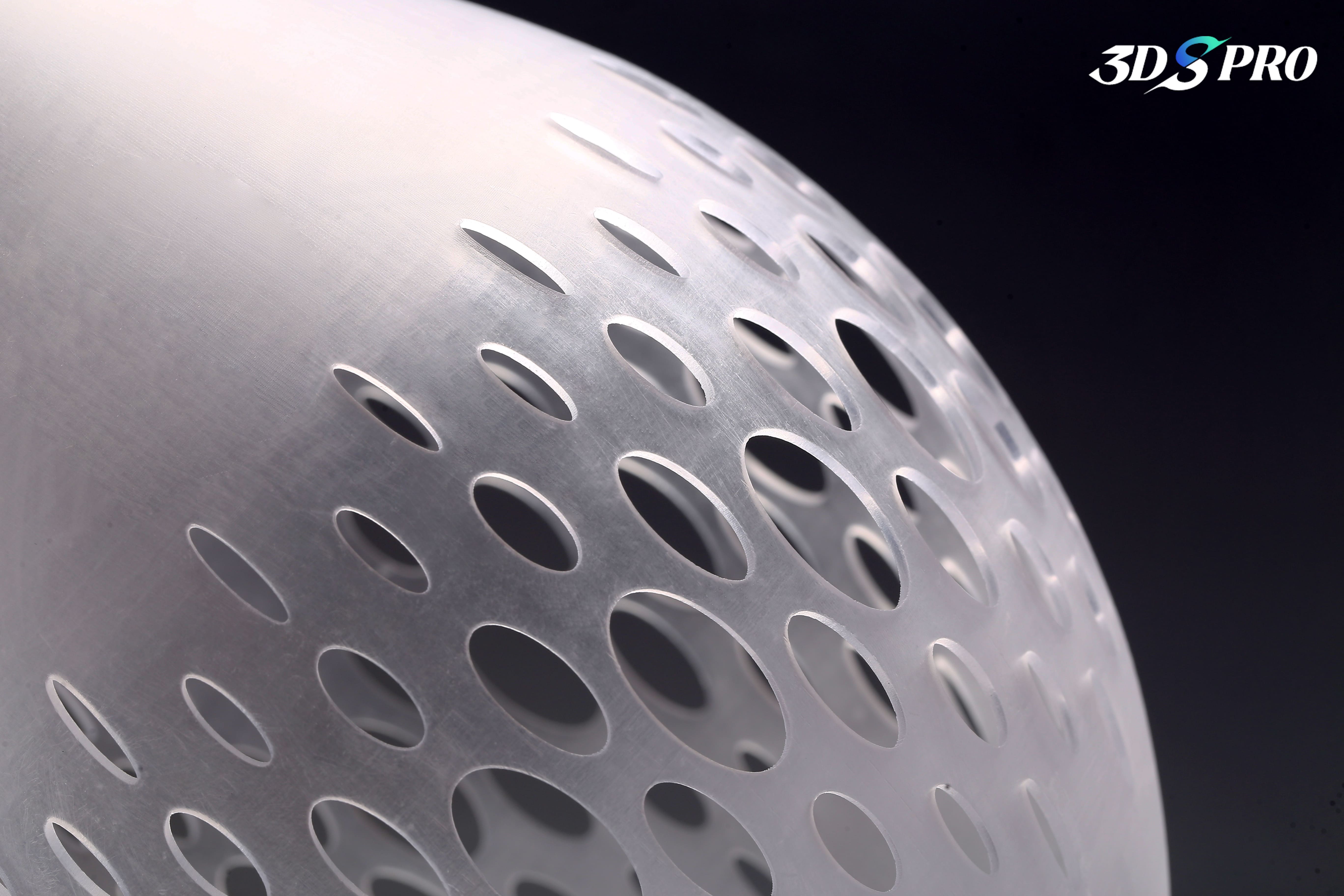

Translucency

Translucency in 3D printing refers to a post-processed transparent resin part that allows light to pass through but scatters it to a degree that makes objects behind it appear blurry or diffuse. It is well suited for applications such as lighting fixtures, decorative objects, and certain medical devices.

Key Features of Translucency:

1. Translucent 3D prints scatter light as it passes through, creating a soft diffuse light. They are ideal for lampshades, light diffusers and decorative panels.

2. The level of translucency can be precisely controlled through material selection, layer thickness, and post-processing techniques.

3. Translucent printing has a unique visual effect and is often used in decorations, art installations and consumer products.

4. Achieving a smooth surface is critical for translucent printing to ensure even light diffusion.

Frosting

Frosting in 3D printing refers to a surface treatment that scatters light, giving printed parts a matte or opaque appearance similar to frosted glass. It is often used to enhance the aesthetics of a part or to diffuse light for specific applications.

Key Features of Frosting:

1. Frosted 3D prints scatter light in multiple directions, reducing glare and creating a soft, diffused look. They are useful for applications such as lighting fixtures, privacy screens, and decorative items.

2. The frosted finish gives resin 3D prints an elegant appearance, making them suitable for high-end consumer products, artistic sculptures, and interior design elements.

3. Achieving a frosted finish involves techniques such as light sanding, chemical etching, or the application of frosted coatings, which creates a uniform matte surface that enhances the visual and tactile qualities of the part.

4. Frosted surfaces can also provide functional benefits, such as reducing fingerprints and smudges on touch surfaces, improving grip, and minimizing reflections in optical applications.

What kind of surface treatment do you want for your clear resin parts?

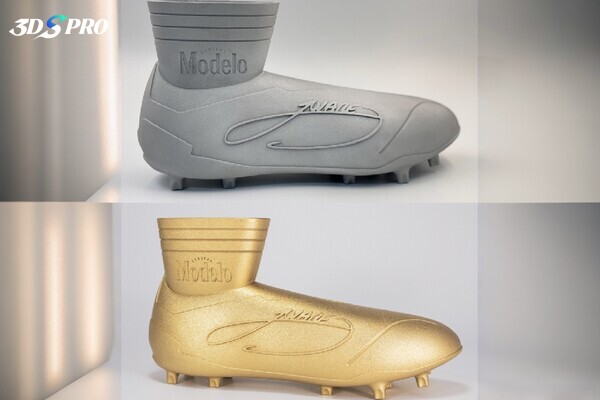

We specialize in creating custom surface finishes for your clear resin 3D prints to meet your unique requirements. Whether you're looking for a transparent, glass-like finish, a soft, translucent glow, a frosted, matte surface, or any other specific treatment, our 3D Plus™ post-processing services can help you and meet your needs. Our tailored hardware solutions enhance the aesthetic and functional properties of your parts, delivering the desired finish for the final application of your parts. If you have any special requests, we will be happy to help you! Feel Free to Contact Us!

COMMENTS

- Be the first to share your thoughts!