What is Delrin?

Delrin, also referred to as POM-H (Polyoxymethylene Homopolymer), is a high-performance engineering plastic. First identified by German chemist Hermann Staudinger in 1920 and later commercially produced by DuPont in 1956, Delrin is a member of the POM (Polyoxymethylene) family of materials, which also includes copolymer acetal (POM-C).

Delrin is known for its excellent mechanical properties, with high strength, high stiffness and outstanding dimensional stability. Delrin operates effectively over a wide temperature range from -40°C to 120°C and exhibits excellent resistance to moisture, chemicals, and abrasion.

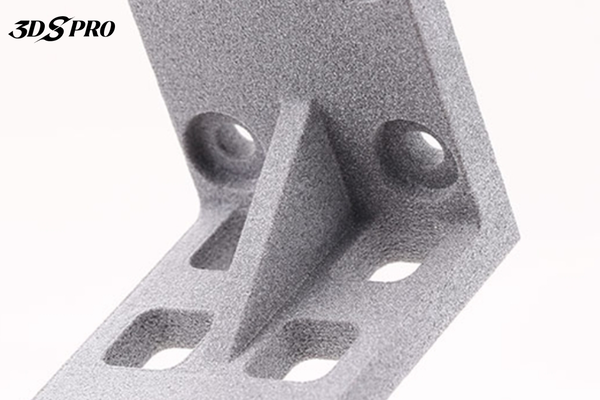

Delrin is highly versatile and can be found in a wide range of industries, including automotive, consumer electronics and medical technology. It is frequently used to manufacture high-performance components such as gears, bearings, bushings and electrical insulators.

Properties of Delrin Material

Mechanical Properties

- High Strength and Stiffness: Delrin has exceptional tensile strength and stiffness. It can withstand heavy loads and maintain its shape under stress.

- Low Friction and Wear Resistance: Delrin is ideal for applications with sliding or rotating parts as it resists wear and tear, ensuring long-lasting performance.

- High Fatigue Resistance: Delrin can endure repeated stress and strain without significant degradation.

Thermal Properties

- Wide Operating Temperature Range: Delrin can perform effectively from -40°C to 120°C without losing its mechanical properties.

- Thermal Stability: Delrin maintains its dimensional stability and performance even when exposed to varying temperatures.

Chemical Resistance

- Resistant to Solvents and Chemicals: Delrin resists many common solvents, oils, and chemicals.

- Moisture Resistance: Unlike certain plastics, Delrin does not absorb significant amounts of moisture.

Electrical Properties

Delrin is an excellent electrical insulator, so it does a good job of isolating electrical components.

Biocompatibility

Delrin is biocompatible. It can be safely used in medical devices that come into contact with the human body.

Delrin Plastic is Used in Various Industries

- Automotive Industry: Delrin is frequently used for manufacturing fuel system components, seat belt mechanisms, and various small gears and bearings.

- Consumer Electronics: Delrin is used to create components such as camera parts, printer gears, connectors, and electrical housing.

- Medical Devices: Delrin is used to manufacture a variety of medical devices, including insulin pens, surgical instruments, and prosthetic components.

- Industrial Machinery: Delrin is utilized for producing gears, conveyor belts, and valve components.

- Food and Beverage Industry: Delrin is often used to create conveyor belts, filling machine parts, and cutting tools.

- Aerospace: It is used in various applications, including aircraft interior components, control knobs, and instrumentation parts.

Delrin 3D Printing

Delrin is an engineering thermoplastic available in filament form for use with Fused Deposition Modeling (FDM) 3D printers. 3D printed Delrin parts are highly durable and exhibit low friction. They are suitable for applications that require strong, wear-resistant components, including gears, bearings, bushings, etc.

However, 3D printing with Delrin has challenges. Delrin 3D printer filaments have a high melting point and need to be processed at high temperatures, so a printer capable of maintaining a constant high temperature and equipped with a heated bed must be used to minimize warping and ensure proper adhesion. Therefore, it is more difficult to process compared to more common 3D printing materials like PLA or ABS.

Successfully 3D printing Delrin requires proper preparation and a thorough understanding of Delrin’s properties. You need to properly equip your 3D printer and fine-tune the settings to overcome the inherent difficulties of printing with Delrin.

Tips to 3D Print Delrin

1. Set the nozzle temperature between 180°C and 220°C.

2. Keep the bed temperature between 90°C and 110°C for better adhesion.

3. Apply an adhesive like a glue stick or use a textured print surface.

4. Use an enclosure to maintain a stable temperature and prevent warping.

5. Print at slower speeds (20-40 mm/s) to improve layer adhesion.

6. Turn off cooling fans to prevent warping.

7. Keep the Delrin filament dry to prevent moisture absorption.

Acetal vs Delrin

Acetal and Delrin belong to the polyoxymethylene (POM) family, but they come in two different forms: polyoxymethylene copolymer (POM-C) and polyoxymethylene homopolymer (POM-H), the latter of which is called Delrin. Acetal and Delrin are often compared due to their similar properties, but there are distinct differences between them that can affect their suitability for various applications.

|

Property |

Acetal |

Delrin |

|

Composition |

Multiple chemical compounds |

Single monomer |

|

Strength and Stiffness |

High, but less than Delrin |

Higher tensile strength and stiffness |

|

Fatigue Resistance |

Good |

Superior |

|

Wear Resistance |

Good |

Excellent |

|

Temperature Range |

Broad |

Slightly higher |

|

Thermal Stability |

Good |

Better under continuous heat |

|

Chemical Resistance |

Better hydrolysis and alkali resistance |

Excellent, but less resistant to strong alkalis and hot water |

|

Machinability |

Easier to machine, less porosity |

Machinable, but needs precise control |

|

Common Applications |

Plumbing, food processing |

Automotive, mechanical parts, bearings, gears |

COMMENTS

- Be the first to share your thoughts!

Check out Our Special Offers

Featuring Process

Featuring Materials

- Coming Soon