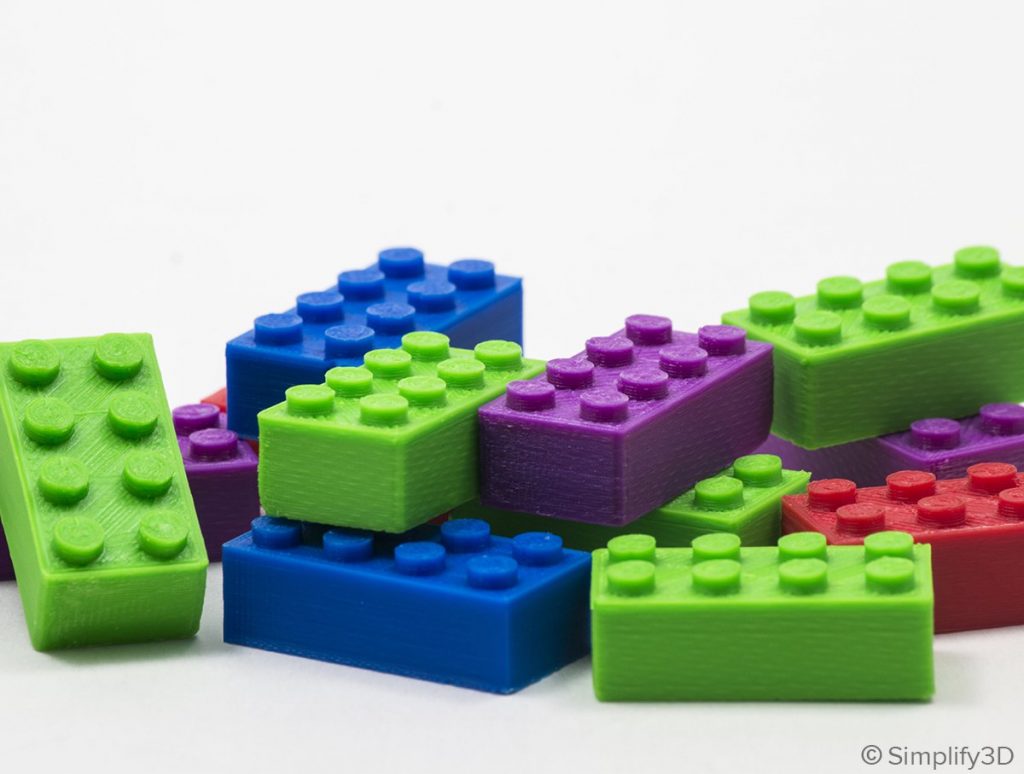

Understand Types of 3D Printing Plastic Materials

Thermoplastics

Thermoplastics are a class of polymers that become pliable or moldable at a specific elevated temperature and solidify upon cooling. They are particularly favored in 3D printing for their ease of use and versatility:

● ABS (Acrylonitrile Butadiene Styrene): A strong and durable material, ideal for items that require toughness and heat resistance.

● PLA (Polylactic Acid): Known for its ease of printing and biodegradability, making it a popular choice for hobbyists and educational purposes.

● PETG (Polyethylene Terephthalate Glycol): Combines the ease of PLA with the strength and durability of ABS and also has good chemical resistance.

● Nylon: A synthetic polymer known for its flexibility and toughness. It’s highly resistant to wear and abrasion, making it suitable for functional parts that require durability.

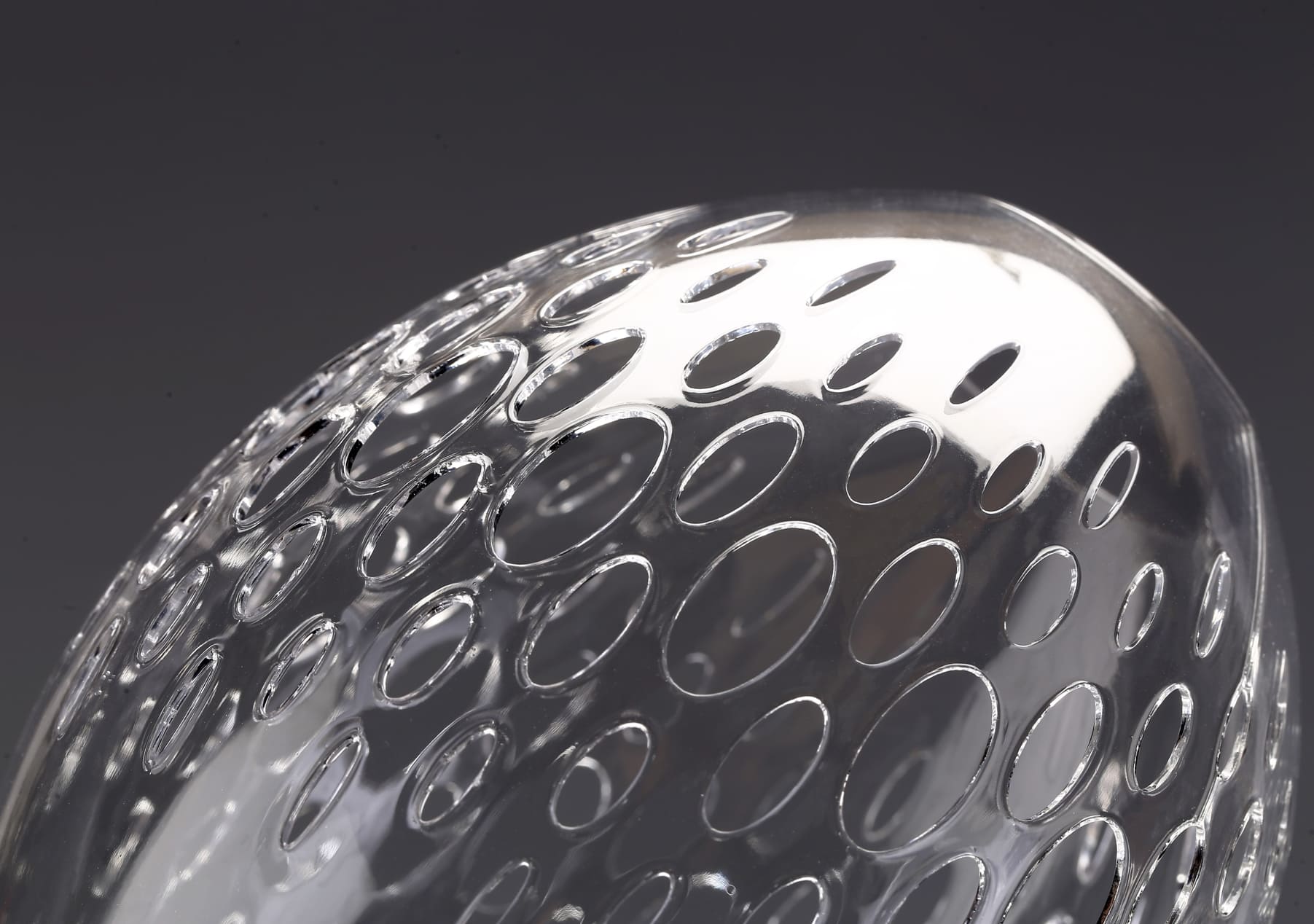

Resins

In 3D printing, resins are liquid photopolymers that harden when exposed to a specific light source. They are used in processes like SLA and DLP. Resins offer:

● High Detail: Suitable for intricate designs and fine features.

● Smooth Surface Finish: Provides a professional appearance to the printed parts.

Polyurethanes

Polyurethanes (PU) are versatile materials that can range from soft and flexible to rigid and tough. In 3D printing, thermoplastic polyurethane (TPU) is a popular choice as it can bend and stretch. TPU is perfect for phone cases, wearable devices, and gaskets.

Composite Materials

These are plastics mixed with other materials to enhance certain properties, such as:

● Carbon Fiber Reinforced PLA: Adds stiffness and strength to standard PLA, suitable for structural components that require light weight and high rigidity.

Image Source: Simplify3D

Define the Final Performance of Your 3D Printed Parts

Defining the final performance of your 3D-printed parts is a critical step in the material selection process. It involves understanding how the part will be used and what conditions it will face.

Identify the Application

First, consider the application of the part. Will it be a structural component, a prototype, or a cosmetic piece? The application will largely dictate the performance requirements.

Determine Mechanical Requirements

Mechanical properties such as tensile strength, flexibility, and impact resistance are crucial. For instance, parts that will bear loads or experience stress will require materials with high tensile strength.

Assess Environmental Conditions

Evaluate the environmental conditions the part will be exposed to, including temperature extremes, UV exposure, chemicals, and moisture. Materials like ABS and Nylon are known for their thermal and chemical resistance.

Consider Aesthetics

For parts where appearance is important, consider materials that offer a smooth finish or can be easily painted or treated. Resins used in SLA printing are known for their smooth surfaces and fine details.

Evaluate Lifespan and Durability

How long does the part need to last? Will it be a single-use item or something that requires longevity? Material like Nylon is durable and suitable for long-term use.

Understand the Impact of Printing Parameters

The printing parameters, such as layer height, infill density, and nozzle temperature, can significantly affect the performance of the printed part. Optimal settings can enhance strength and surface finish.

Conduct Fatigue Analysis

If the part undergoes repeated stress, it’s important to understand its fatigue properties. This is especially relevant for functional parts in machinery or devices.

Perform Testing

Finally, perform physical testing on prototypes to ensure that the material and print settings meet the performance criteria. This step can save time and resources in the long run.

Image Source: Simplify3D

Material Selection Considerations

Durability

Durability refers to the ability of a material to withstand wear, pressure, or damage. When evaluating durability, consider:

● Wear Resistance: How the material holds up against repeated friction and use. For example, Nylon is known for its excellent wear resistance.

● Impact Resistance: The material’s ability to absorb energy without deforming. ABS is a good choice for parts that might experience impacts.

● Fatigue Strength: The endurance limit of a material under cyclic load. Polycarbonate (PC) is often chosen for its high fatigue strength.

Flexibility

Flexibility determines how a material can bend or stretch without breaking. It’s important to consider:

● Elasticity: The ability of a material to return to its original shape after deformation. TPU (Thermoplastic Polyurethane) is highly elastic and returns to shape after stretching.

● Rigidity: If a part needs to maintain its shape under stress, materials like PLA or ABS offer more rigidity.

● Ductility: The extent to which a material can deform under tensile stress. Nylon is a ductile material, making it suitable for parts that require some give.

Temperature Resistance

Temperature Resistance is crucial for parts exposed to varying temperatures. Consider:

● Melting Point: The temperature at which a material will melt. PEEK (Polyether Ether Ketone) has a high melting point, suitable for high-temperature applications.

● Thermal Expansion: Materials like PLA have a higher coefficient of thermal expansion and may deform in heat, while ABS has better thermal stability.

Chemical Resistance

Chemical Resistance is the material’s ability to resist degradation due to exposure to chemicals. Key points include:

● Solvent Resistance: Some plastics like PETG resist solvents well, making them ideal for chemical containers.

● Reactivity: Materials like PP (Polypropylene) are less reactive and can handle a wide range of chemicals without degrading.

Cost

Cost is always a consideration in material selection. It involves:

● Material Cost: The raw price of the material itself.

● Operational Cost: The cost related to printing with the material, including energy consumption and printer wear. Materials that print at lower temperatures, like PLA, can be less costly in terms of operational expenses.

Image Source: Simplify3D

3D Printing Processes for Plastic Materials

● Fused Deposition Modeling (FDM): Ideal for prototyping and functional parts, FDM works with a range of thermoplastics and is known for its ease of use and material availability.

● Stereolithography (SLA): Offers high resolution and smooth surface finishes, suitable for detailed models and molds.

● Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF): Provides strong and durable parts without the need for support structures, perfect for complex geometries.

Image Source: Simplify3D

Research and Compare Common Materials

ABS (Acrylonitrile Butadiene Styrene)

Pros: High strength, good durability, and heat resistance. It’s suitable for parts that require toughness.

Cons: Produces fumes during printing, requires a heated bed and is prone to warping.

PLA (Polylactic Acid)

Pros: Biodegradable, made from renewable resources, easy to print with, and does not require a heated bed.

Cons: Not as heat resistant as ABS, can deform in hot environments, and has lower strength.

PETG (Polyethylene Terephthalate Glycol)

Pros: Combines the ease of printing of PLA with the strength and durability of ABS. It’s also chemically resistant and has a glossy finish.

Cons: It can be sticky during printing, which may lead to stringing or blobbing.

Nylon

Pros: High strength and flexibility, excellent wear resistance, and good impact resistance.

Cons: Absorbs moisture from the air, which can affect print quality and requires dry storage.

TPU (Thermoplastic Polyurethane)

Pros: Flexible and elastic, good impact resistance, and durable. Ideal for parts that require bending or stretching.

Cons: It can be challenging to print due to its flexibility and may require specific printer settings.

PEEK (Polyether Ether Ketone)

Pros: Exceptional thermal stability, chemical resistance, and mechanical properties. Suitable for high-performance applications.

Cons: Requires high-temperature printing conditions, making it less accessible for standard 3D printers.

Resins

Pros: Capable of producing parts with high detail and smooth surface finish. Suitable for intricate designs.

Cons: Generally more brittle than thermoplastics, requires post-processing, and has limited material options.

When comparing these materials, consider factors such as the intended use of the part, the required mechanical properties, and the printing conditions you can provide. Each material has its strengths and weaknesses, and the best choice will depend on the specific requirements of your project.

Image Source: Simplify3D

COMMENTS

- Be the first to share your thoughts!