What is polycarbonate filament?

Polycarbonate (PC) filament is a high-performance thermoplastic widely used in 3D printing for its exceptional strength, durability, and heat resistance.

PC filament is made from polycarbonate polymer, which is renowned for its impact resistance and optical clarity. It is often used in applications requiring high structural integrity and resistance to physical stress.

Despite being slightly more challenging to print with compared to standard filaments like PLA and ABS, polycarbonate filament is valued for producing parts that can withstand significant wear and tear. It is ideal for functional prototypes, mechanical parts, and durable consumer products.

Image Source: Simplify3D

Properties of PC Filament

High Strength and Durability

PC filament is strong and durable, capable of withstanding significant physical stress and impact. It is ideal for producing robust, functional parts that need to endure heavy use.

Heat Resistance

PC filament can withstand temperatures up to 110°C (230°F) without deforming, making it suitable for parts exposed to high temperatures or requiring thermal stability.

Optical Clarity

PC filament is known for its transparency and optical clarity, which is why it's often used for applications like light covers, lenses, clear containers, etc.

Impact Resistance

Polycarbonate is highly impact-resistant. It can absorb and dissipate energy from impacts without cracking or breaking.

Flexibility

Despite its strength, PC filament also offers a degree of flexibility. It is less brittle compared to other filaments like ABS, which allows for slight bending and flexing without breaking.

Chemical Resistance

PC filament exhibits good resistance to many chemicals, including oils, greases, and solvents.

UV Resistance

Polycarbonate has excellent resistance to ultraviolet (UV) radiation, reducing the risk of degradation and discoloration when exposed to sunlight over time. Considering this property when the part is used for outdoor applications.

Electrical Insulation

PC filament provides excellent electrical insulation properties. It is ideal for components that need to isolate electrical currents and prevent short circuits.

Image Source: Overture

How to Print with PC Filament

Printing with polycarbonate filament requires some specific considerations to achieve the best results due to its unique properties:

- Print Temperature: PC filament requires a high print temperature, typically between 260°C and 310°C.

- Bed Temperature: Set the bed temperature between 90°C and 120°C to ensure proper adhesion of the first layer. Use a heated bed with an appropriate surface like glass or PEI to help with adhesion.

- Enclosure: Use an enclosed build chamber. It helps maintain a stable temperature, reducing the risk of warping and layer separation due to temperature fluctuations.

- Bed Adhesion: To prevent warping, use adhesives like a glue stick or PEI sheet on the print bed. Ensure the first layer is properly adhered to the bed by adjusting the bed leveling and first layer height.

- Cooling: Use minimal or no part cooling fan. Polycarbonate tends to warp if cooled too quickly.

- Print Speed: Print at a moderate speed, typically between 30mm/s and 60mm/s. Slower speeds help improve layer adhesion and overall print quality.

- Layer Height: For best results, use a layer height between 0.1mm and 0.2mm, which helps achieve a smooth surface finish and strong layer bonding.

- Retraction Settings: Use a retraction distance of 1-1.5mm and a retraction speed of 20-30mm/s to reduce stringing without causing jams or clogs.

- PC Filament Storage Tips: Polycarbonate absorbs moisture from the air. Always dry your filament before printing by using a filament dryer or an oven at 80°C for a few hours, as moisture can cause bubbling and poor print quality.

Image Source: 3DGence

Types of PC Filaments

Polycarbonate (PC) filaments come in various formulations, and each type of PC filament offers unique benefits for specific applications:

Standard PC Filament

The most common type of polycarbonate filament. Known for its high strength, durability, and heat resistance. Ideal for producing functional prototypes, mechanical parts, and other durable items.

Transparent PC Filament

Known for its optical clarity and excellent transparency, transparent PC filament is used in applications requiring clear visibility, such as lenses, light covers, and display models.

PC Carbon Fiber Filament

PC CF filament is reinforced with carbon fibers, enhancing its strength, stiffness, and durability. It is perfect for applications requiring high-performance materials with superior mechanical properties.

PC-ABS Blends

PC ABS blends combine polycarbonate with ABS (Acrylonitrile Butadiene Styrene), resulting in a material that offers improved impact resistance and better printability. It is great for applications that require a balance between strength and ease of printing.

PC-PBT Blends

A blend of polycarbonate and Polybutylene Terephthalate (PBT) that provides excellent chemical resistance, impact strength, and thermal stability. Ideal for parts exposed to harsh environments or chemicals.

Flame-Retardant PC Filament

Designed to meet stringent safety standards for flammability, this filament is ideal for producing parts used in electrical, automotive, and aerospace applications.

Image Source: SUNLU

PC Filament Pros and Cons

Pros of PC Filament

1. PC filament is known for its exceptional mechanical properties, providing parts with high strength and impact resistance.

2. Polycarbonate has a high glass transition temperature, typically around 110°C, which means it can endure higher temperatures without deforming.

3. PC filament can produce transparent parts, which is useful for applications that require clear, see-through components like lenses or light covers.

4. Polycarbonate exhibits good resistance to many chemicals, including oils, greases, and certain solvents.

5. One of the key advantages of PC filament is its ability to absorb impact without cracking or breaking.

6. PC filament offers excellent resistance to UV radiation, reducing the risk of degradation and discoloration when exposed to sunlight over time.

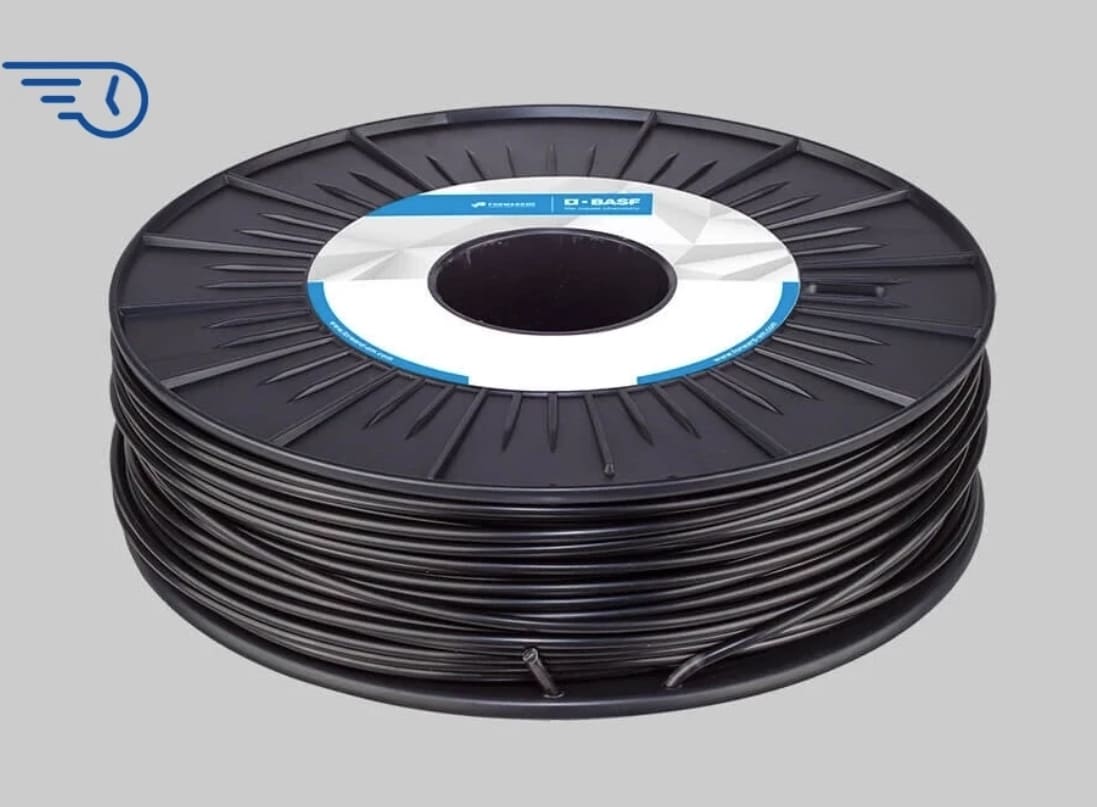

Image Source: Forward AM

Cons of PC Filament

1. PC filament requires high temperatures for printing and bed adhesion, making it more challenging to print with compared to standard filaments like PLA or ABS.

2. Due to its high thermal contraction, PC filament is prone to warping during the printing process.

3. Can lead to bubbling and poor print quality if not properly dried before use.

4. Achieving a smooth and polished finish with PC filament may require additional post-processing steps like sanding and polishing.

5. Polycarbonate filament tends to be more expensive than other common 3D printing materials like PLA and ABS.

PC Filament Applications

1. Functional Prototypes: PC filament's high strength and impact resistance make it ideal for prototypes of mechanical parts, enclosures, etc.

2. Automotive Parts: The automotive industry leverages PC filament to produce components such as brackets, housings, and interior parts.

3. Aerospace Components: PC filament is valued for its strength-to-weight ratio and heat resistance. It's used to create lightweight, durable parts such as brackets, clamps, and housing units.

4. Consumer Electronics: PC filament is often used in the production of electronic housings, protective cases, and other parts that require impact resistance and durability.

5. Lighting Covers and Lenses: Thanks to its optical clarity, PC filament is ideal for producing transparent parts like lighting covers, lenses, and optical components.

6. Outdoor Equipment: Due to its UV resistance and durability, PC filament is suitable for outdoor applications.

Image Source: MatterHackers

COMMENTS

- Be the first to share your thoughts!