No longer limited to rapid prototyping, 3D printing has matured into a core manufacturing method for functional vehicle parts, ranging from intricate engine components to specialty interior trims and structural assemblies. With leading manufacturers such as Ford, BMW, Volkswagen, and Bugatti integrating high-performance 3D printed parts into production and aftermarket scenarios, the competitive edge offered by this technology is now a crucial differentiator.

Accelerated Prototyping & Development

3D printing’s most transformative contribution to the automotive industry is rapid prototyping. Traditionally, creating physical vehicle prototypes, functional models, or even simple components required weeks or months, significant tooling, and high costs—factors that could stifle innovation and delay market entry. Additive manufacturing shortens the production development cycle dramatically by enabling direct fabrication from digital designs, eliminating the need for intermediate tooling.

Key benefits of accelerated prototyping:

• Speed: Functional prototypes can be produced in hours or days, not weeks.

• Iterative Development: Designers and engineers can quickly test, refine, and re-test multiple iterations of a part or assembly, leading to better products with fewer production-stage corrections.

• Collaboration and Feedback: Physical prototypes facilitate communication across engineering and design teams, helping align goals and catch errors early.

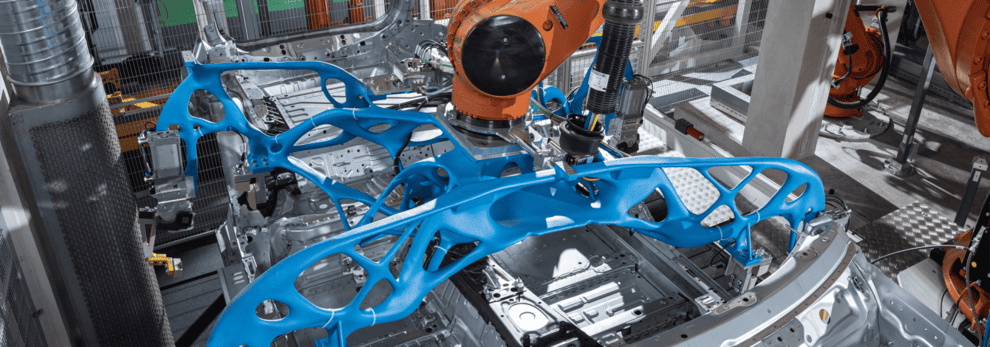

Notably, manufacturers like BMW and Porsche now employ 3D printing for functional prototypes and aerodynamic testing. The technology underpins projects like the BMW Additive Manufacturing Campus, which produces thousands of prototypes and work aids annually at reduced complexity and cost.

Image Source: BMW

Cost Efficiency in Low-Volume Production

The economics of automotive manufacturing traditionally depend on volume. High upfront tooling and redundant setup expenses are justified only for mass production, making low-volume or custom projects prohibitively expensive. 3D printing shines by democratizing access to advanced manufacturing at virtually any scale.

Cost advantages of 3D printing in low-volume production:

• No Tooling Costs: Parts are produced directly from digital files, without costly molds, dies, or jigs.

• Short Runs, Niche, or Aftermarket Parts: 3D printing is ideal for batches from a single unit to a few thousand, enabling production for specialty vehicles, commercial one-offs, or legacy model restorations.

• Economical for Prototypes and Bridge Production: Bridge manufacturing—producing parts while gearing up for mass production—leverages 3D printing for quicker market entry and risk-free testing.

• Reduced Inventory and Waste: Pieces can be printed as needed, slashing warehousing and overproduction costs, and avoiding obsolescence for rare or discontinued parts.

3D printing’s cost efficiency is especially evident in specialized scenarios—custom body kits, limited-edition trims, aftermarket modifications, and classic car part replacement—making it a versatile solution for both OEMs and car enthusiasts.

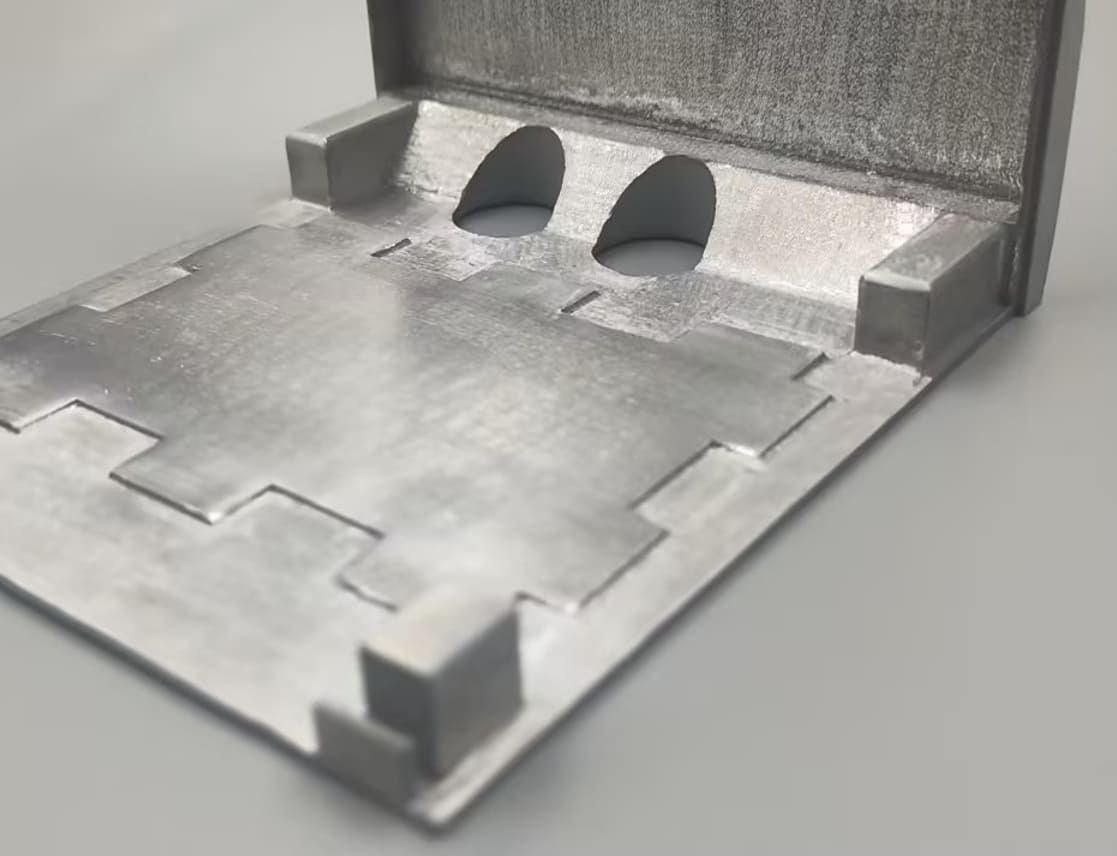

Design Freedom & Complex Geometries

One of 3D printing’s most talked-about benefits is design freedom. Traditional manufacturing limits parts to geometries that match tool or mold capabilities. Additive methods, however, build components layer-by-layer, enabling shapes previously deemed impossible.

Key elements of design freedom and complexity:

• Intricate Structures: Lattice and honeycomb structures can be realized, reducing material use and overall weight without compromising strength—this is critical in lightweighting efforts for improved fuel efficiency and electric vehicle range.

• Topology Optimization: Advanced design software allows engineers to algorithmically optimize a part’s structure, removing unnecessary mass and enhancing performance.

• Part Consolidation: Multiple components can be combined into a unified structure, reducing assembly steps, fasteners, and points of failure.

• Function Integration: Integrated cooling channels or ducts, impossible to achieve with traditional casting or machining, can enhance engine cooling or heat dissipation, for example, in turbochargers or battery pack housings.

Bugatti’s 3D printed titanium brake caliper for the Chiron supercar is 40% lighter and offers higher strength than its forged aluminum counterpart. Traditional means could not machine titanium to this geometry; additive processes using selective laser melting enabled not just the weight reduction but intricate, organically inspired structures.

On-Demand Manufacturing & Supply-Chain Agility

In today’s volatile global environment, supply chain agility and responsiveness are paramount. 3D printing’s on-demand manufacturing upends traditional distribution and inventory management, providing resilience and flexibility.

Advantages of supply-chain management:

• Digital Inventory: Designs are stored digitally and only turned into physical parts when needed, reducing the need to stockpile vast inventories of specialized components.

• Localized, Distributed Production: Parts can be manufactured at or near the point of use, reducing reliance on centralized factories and lengthy, costly logistics chains. Localization improves lead times and offers protection against global disruptions.

• Predictive, Just-in-Time Manufacturing: Integration with IoT and enterprise inventory systems means parts are produced only when sensors or maintenance schedules indicate demand, reducing waste from overproduction or obsolescence.

• Rapid Response to Emergencies and Change: Whether responding to a part failure, product recall, or urgent update, 3D printing excels at quick turnarounds that are impossible with tooling-dependent production.

Automakers such as Ford and BMW are increasingly linking their manufacturing systems to cloud-based digital inventories, enabling hybrid supply chains that flex resources as business needs change.

Image Source: Formlabs

Customization & Personalization

Today’s automotive market is increasingly driven by personalization and unique configurations. 3D printing enables true mass customization at scale, allowing manufacturers, tuners, and enthusiasts to tailor vehicles as never before.

Personalization enabled by 3D printing:

• Unique Interior and Exterior Features: From bespoke dashboard trims and shift knobs to custom body panels and light housings, 3D printing brings one-off designs to life for individual customers or special edition runs.

• Functional Customization: Performance upgrades can be optimized for a specific vehicle’s configuration; for instance, custom-fit intake manifolds, aerodynamic components, or engine bay accessories.

• Restoration and Rare Parts: Classic car restorers and collectors can reproduce obsolete or hard-to-find components with complete accuracy—even improving on the original design with optimized materials or finishes.

• Digitally Assisted Personalization: CAD and generative design tools paired with additive manufacturing allow car seats, brackets, and aesthetic trim to be tailored for user comfort or style preferences—all without the penalty of special tooling or prohibitive MOQ minimums.

Implementation Considerations

Material Selections

|

Category |

Material |

Typical Use / Benefit |

|

Concept prototypes (fine detail, smooth finish) |

||

|

PLA |

Prototypes & interior accents (easy printing, low warping) |

|

|

ABS |

Structural & exterior parts (higher impact resistance, heat resistance) |

|

|

Toughness & wear resistance (gears, functional parts) |

||

|

ASA |

UV resistance (outdoor applications) |

|

|

PETG |

Mechanical resilience (good strength & chemical resistance) |

|

|

Flexibility & elasticity (gaskets, wearable parts) |

||

|

Composites |

Carbon-fiber-filled polymers |

Lightweight structural applications (high stiffness-to-weight ratio) |

|

Increased rigidity and dimensional stability |

||

|

High strength-to-weight, good thermal conductivity (frames, housings) |

||

|

Exceptional strength, corrosion resistance (aerospace, medical implants) |

||

|

Very high strength & load-bearing (tools, fixtures) |

Technology Selection

|

Fused Deposition Modeling (FDM) |

Most common for plastics, affordable and accessible for most applications. |

|

Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF) |

Allow printing of strong, intricate plastic components with high dimensional accuracy and no support structures. |

|

Selective Laser Melting (SLM) |

Used for complex, high-performance metal parts. |

|

Stereolithography (SLA) & Digital Light Processing (DLP) |

Offer high resolution for concept models and intricate, aesthetic elements. |

Design Adaptation

Parts must often be redesigned to leverage additive’s strengths—consolidating features, optimizing internal structures, and planning for finishing or tolerance adjustments.

Quality Assurance and Testing

Ensuring that printed parts meet rigorous quality and safety standards requires robust testing protocols, especially for critical components (e.g., brakes, suspension).

Cost and Scalability

While cost-effective for low- to medium-volume production, 3D printing’s material and equipment costs are still significant for mass production. Energy usage, throughput, and post-processing costs should be assessed case by case.

Order 3D Printed Vehicle at 3DSPRO

3DSPRO’s all-in-one automotive 3D printing platform streamlines every step—from uploading or selecting your CAD or scan files, to choosing from advanced materials (engineering plastics, composites, titanium, aluminum, and more) and cutting-edge processes (SLS, MJF, SLM/DMLS, SLA/DLP). You instantly receive a competitive quote plus expert DfAM and manufacturability guidance, then your parts are produced on industrial-grade printers and finished with over 20 post-processing options (anodizing, vapor smoothing, bead blasting, etc.). With rapid turnaround, dedicated online and on-site support, stringent IP security in private cloud vaults, and tailored solutions for everything from vintage and EV prototypes to mass-market production, 3DSPRO delivers high-performance, end-use automotive parts with transparent pricing and professional quality assurance.

COMMENTS

- Be the first to share your thoughts!