The Pentawards Winning Food Packaging

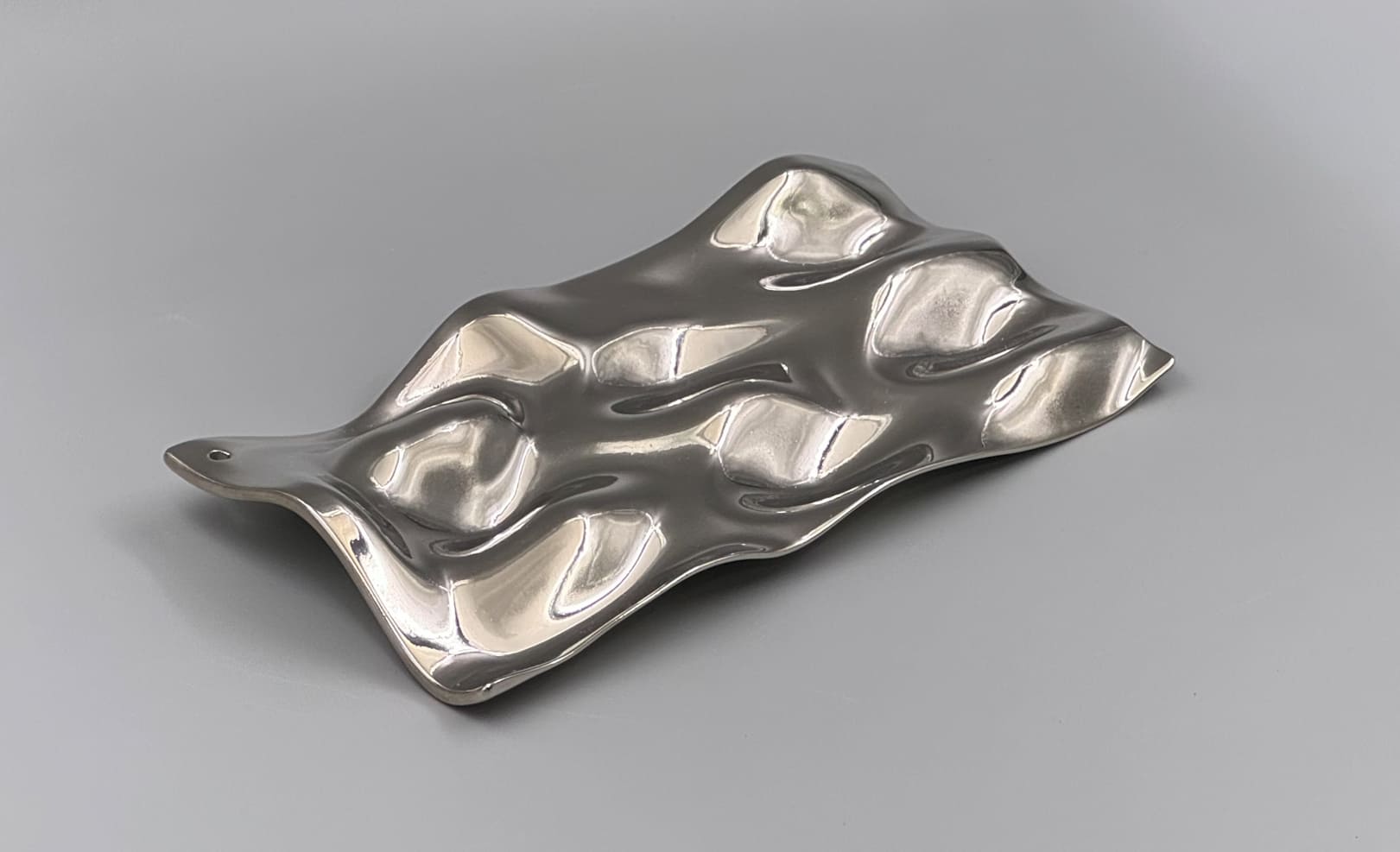

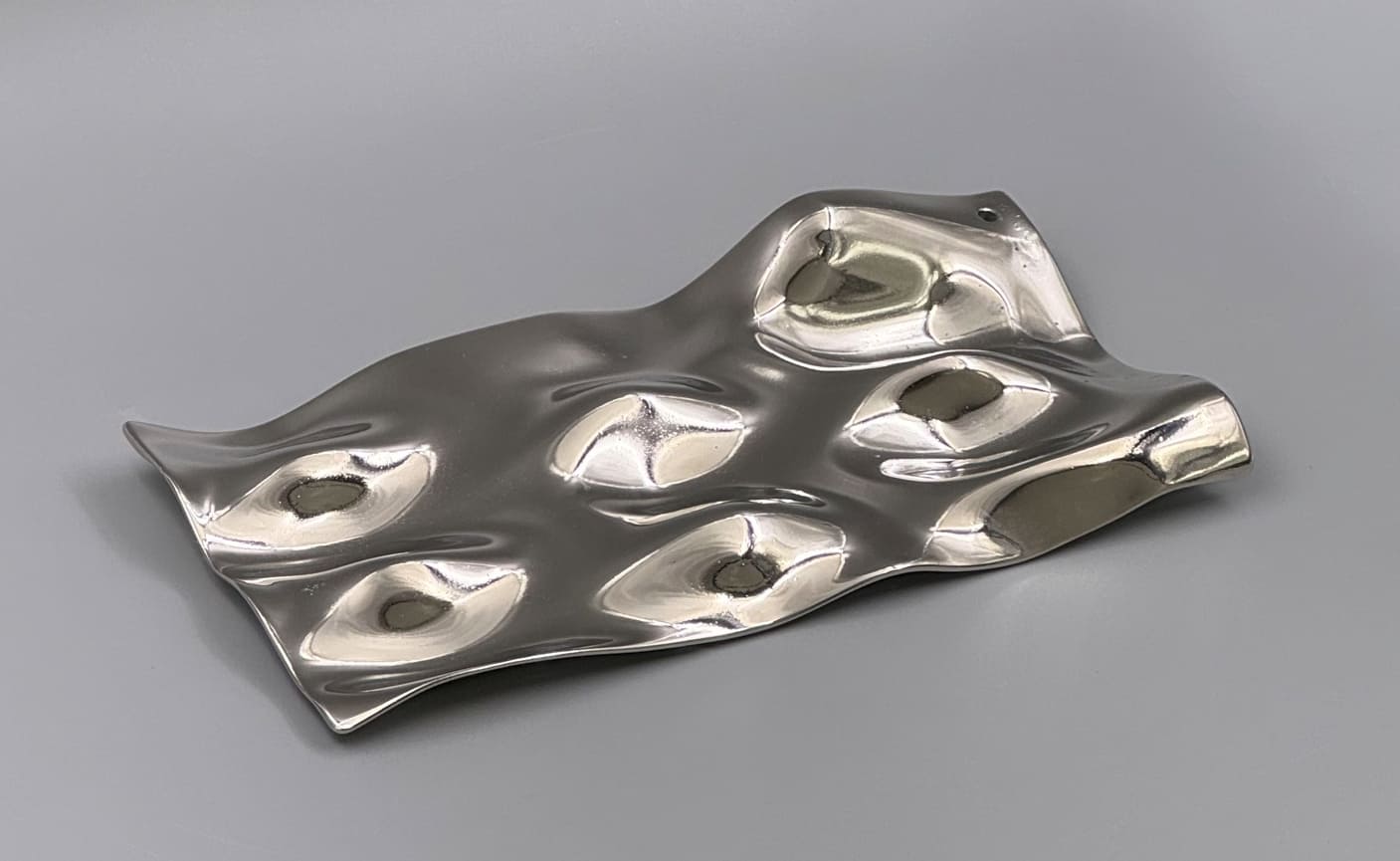

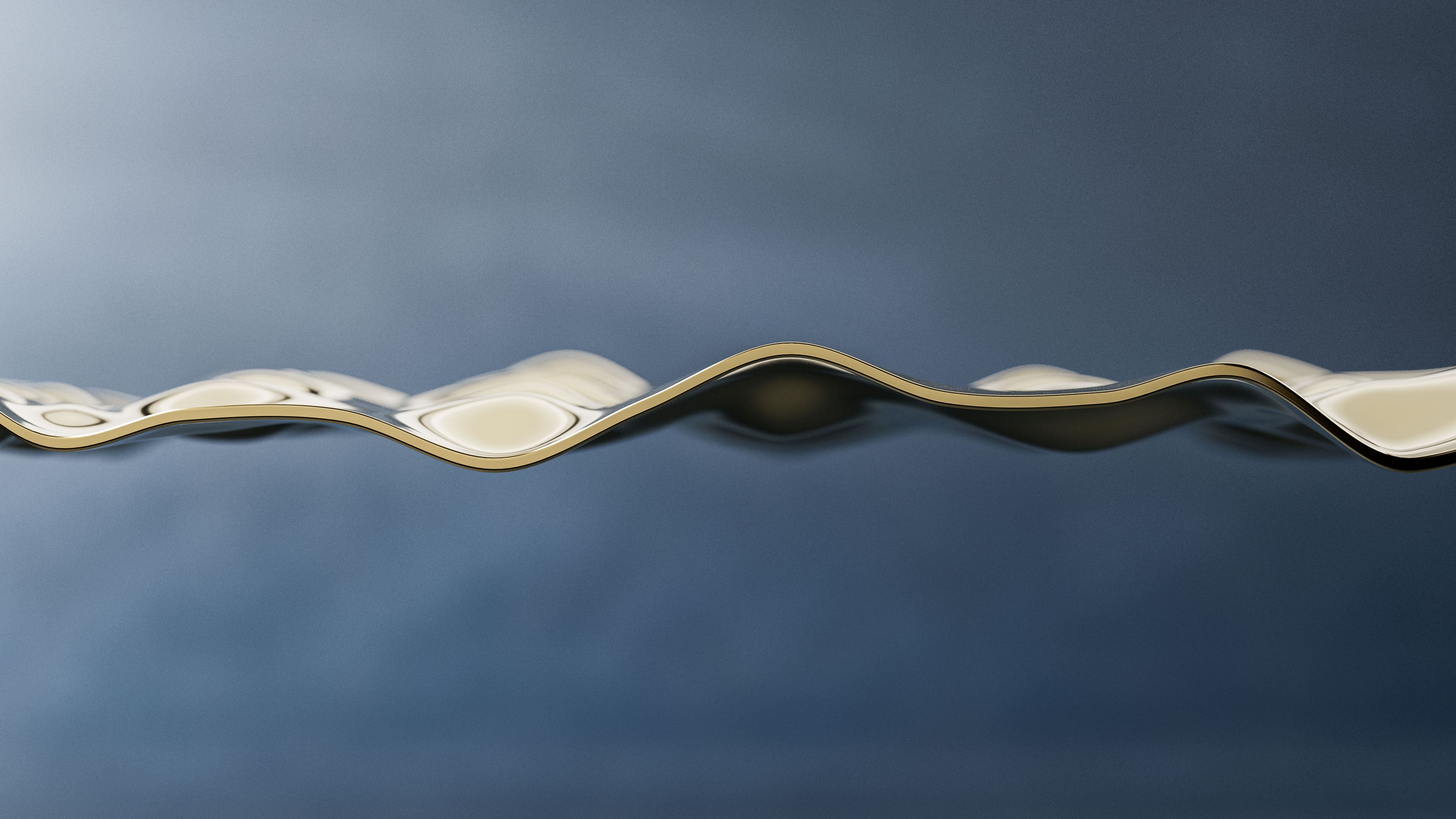

3DSPRO collaborated with NUA and Lazy Snail to produce the award-winning food packaging designs “The Dunes” and “Stem,” winners of the 2024 Pentawards. The project used multiple manufacturing techniques, including metal 3D printing, stamping and CNC machining, to create complex, high-quality packaging.

Using metal 3D printing for rapid prototyping and precise production, enabling the creation of complex geometries and detailed designs; using stamping and CNC machining for serial batches to ensure consistent quality and flawless tolerance.

The collaboration demonstrates 3DSPRO’s ability to combine additive manufacturing and conventional technologies, delivering exceptional custom manufacturing solutions tailored to clients’ specific needs.

Additive Manufacturing Technology Used in the Case

Metal 3D Printing: Selective Laser Melting (SLM 3D Printing)

Metal 3D printing is an advanced technology for creating prototypes with intricate and complex geometries. Selective laser melting is a type of metal 3D printing that utilizes a high-powered laser to selectively melt and fuse metal powder layer by layer, building up detailed and robust metal parts.

Benefits of SLM 3D Printing

- Design Freedom: SLM allows for the creation of complex shapes and intricate details while not compromising the strength.

- Customization: Each piece can be easily customized without the need for expensive tooling changes.

- Strength and Durability: Parts produced with SLM have excellent mechanical properties.

- Materials Variety: Although SLM is a relatively new manufacturing technology, it can work with various metal powders, such as aluminum, titanium, stainless steel, nickel alloy, etc.

Limitations of SLM 3D Printing

- Cost: The technology and materials can be expensive, making it less cost-effective for large-scale production runs.

- Build Size: Due to the build volume limitations of SLM machines, there are limits on the size of parts that can be produced.

- Post-Processing: Parts often require extensive post-processing, such as support removal and surface finishing, to achieve the required quality.

Effect of Metal 3D Printing in this Case

In this project, the use of SLM 3D printing was critical to the success of the food packaging designs “The Dunes” and “Stem”. The technology made it possible to create prototypes with complex geometries and fine details. The ability to rapidly prototype and iterate designs allowed for quick adjustments and improvements, facilitating a more efficient and precise development process.

Conventional Manufacturing Techniques Used in the Case

To meet the production demands for serial batches of the metal parts for "The Dunes" and "Stem" packaging designs, 3DSPRO utilized conventional manufacturing techniques.

Stamping

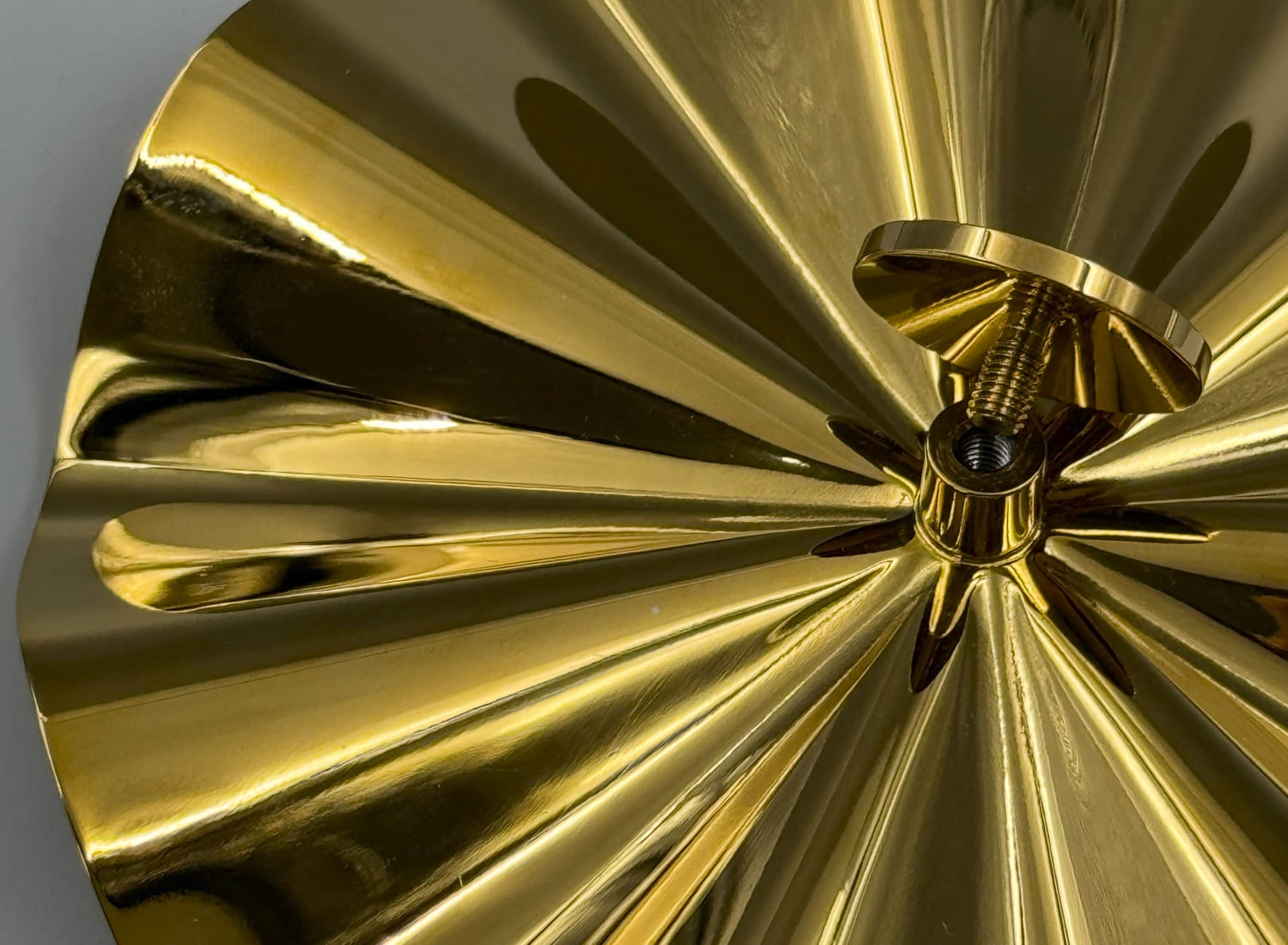

Stamping is a highly efficient manufacturing process that shapes metal sheets into desired forms using a press-and-die setup, which is ideal for producing large quantities of parts with consistent quality and precision. Besides, stamping is suitable for creating exquisite large flat surfaces, so we used it for the "Dunes" and "Stem" metal parts.

By using a stamping process, we can maintain the structural integrity and aesthetics of the part while ensuring that each part meets food safety standards as an end-use part. Additionally, the stamping production process is low-cost and time-efficient, significantly reducing lead times compared to other manufacturing methods.

CNC Machining

For the production of screw parts in the "Stem" packaging design, we used CNC machining, a highly precise and reliable conventional manufacturing technique.

CNC machining was chosen to manufacture screw parts because it can consistently produce parts with tight tolerances and fine details. CNC machined screws ensure the parts fit perfectly. Furthermore, CNC machining offers high efficiency, high precision, and high quality for each part.

Discover the Full Potential of 3DSPRO

We invite you to upload your most complex and ambitious design projects to our platform. Our team of experts is ready to demonstrate our manufacturing capabilities, from 3D printing to traditional techniques. Whether your design involves complex geometries, detailed features or unique material requirements, we accept the challenge!

In addition to the manufacturing solutions mentioned in the case studies, we also provide a wide range of 3D printing services, including SLS, MJF, SLA and DLP 3D printing. Besides, we provide more than 20 post-processing services to meet the needs of better surface finish and quality. From resin and plastic materials to metal materials, we can create what you want.

Challenge us today by uploading your complex design, and discover how 3DSPRO can turn your innovative ideas into reality!

COMMENTS

- Be the first to share your thoughts!