SLM 3D Printing and Its Post-processing

Selective Laser Melting (SLM) 3D printing is a revolutionary additive manufacturing process that fuses fine metal powders using a high-powered laser. This technique is ideal for producing complex geometries and parts with high density and mechanical properties akin to CNC machining.

Post-processing in SLM is not just a necessary step but a key to unlocking the full potential of the technology. It is crucial for achieving the desired surface finish and mechanical characteristics, enhancing the value and quality of the final product.

SLM 3D Printing Post-processing Typically Involves:

1. Cooling: As SLM 3D printing melts parts in a high-energy laser, the printed metal parts have a relatively high temperature. Metal parts thus need cooling after printing.

2. Clean Residue Metal Powder: Metal powders may still exist and attach to the surface. It is necessary to clean residue before going to the next step.

3. Removal of Supports: Structures printed alongside the part to prevent warping are removed.

4. Heat Treatment: To relieve internal stresses and improve mechanical properties.

3. Surface Finishing: Methods like sandblasting or polishing are applied to enhance surface quality.

5. Quality Inspection: Parts are inspected for defects and dimensional accuracy.

Metal Finishing Types

Surface finishing plays a crucial role in enhancing the functionality and aesthetics of metal 3D printed parts. With a wide array of options available, including anodizing, hardening, annealing, spray painting, powder coating, and electroplating, choosing the right treatment can be overwhelming.

To simplify the process, we've categorized these treatments into concise and clear categories, making it easier for you to understand and select the best option for your metal parts. Let's explore your options and get started on achieving the perfect finish!

Methods to Enhance Mechanical Properties

1. Stress Relieving

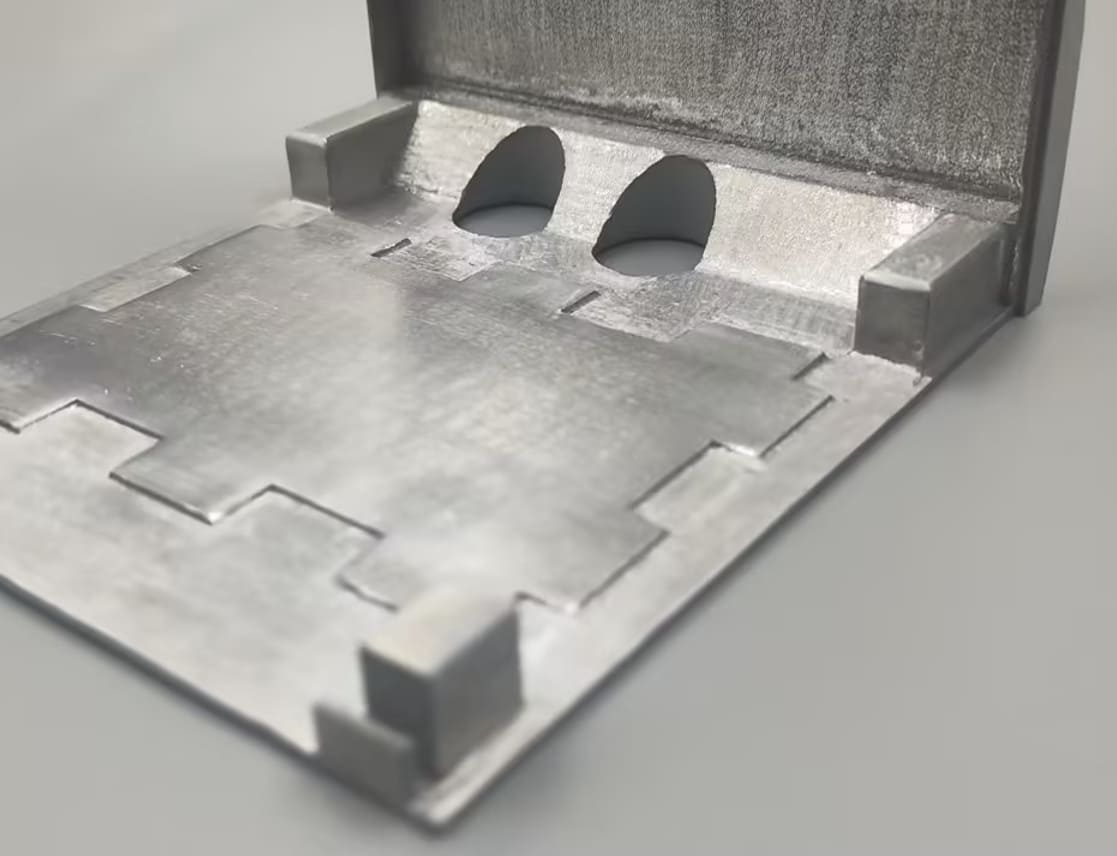

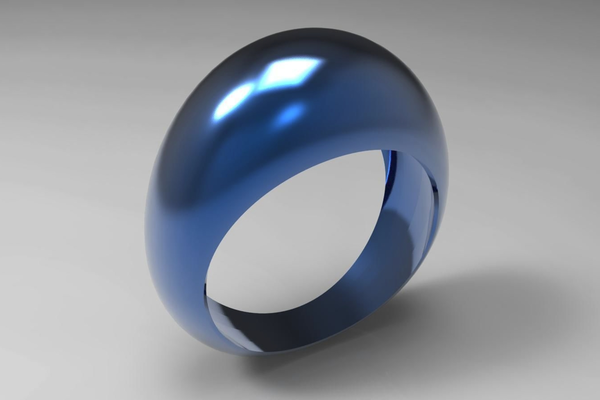

Stress relieving plays a crucial role in the post-processing of metal 3D printed parts. It is a method that significantly enhances the mechanical properties of these parts. The process involves subjecting the component to a specific thermal cycle, which effectively alleviates residual stresses induced during the printing process.

Stress relieving results in a more stable and robust part. It improves dimensional accuracy and significantly reduces the likelihood of warping or cracking during service. This treatment is especially beneficial for components that will be subjected to further machining or those that require a high degree of reliability. By implementing stress relieving, manufacturers can significantly extend the lifespan and performance of the metal 3D printed parts.

Image Sources: Industrial Metallurgists

Annealing

Annealing is a heat treatment process designed to alter the microstructure of materials to enhance their mechanical properties. The primary goal of annealing is to increase ductility, reduce hardness, and improve toughness. For instance, steel, copper, and aluminum are materials that often benefit from annealing. Annealing is particularly beneficial for these materials that have been work-hardened or altered by other manufacturing processes.

Annealing remains a cornerstone technique in materials engineering. It offers a versatile method for tailoring the mechanical properties of materials for specific applications. By understanding and controlling the annealing process, material performance can be significantly improved, extending the lifespan and functionality of components across numerous industries.

Image Source: Make it From Metal

Hardening

Hardening is a critical process in materials science that increases a material's resistance to deformation. This process is essential for applications that require high wear resistance and durability. Several methods exist to achieve hardening, each with its unique approach and benefits.

Work Hardening

Work hardening, also known as strain hardening, is a method of strengthening metal through plastic deformation. The process is achieved by applying stresses that exceed the yield strength of the material, causing dislocations within the crystal structure to multiply and become entangled. The increased dislocation density makes further deformation more difficult, thus increasing the hardness and strength of the material.

Heat Treatment Hardening

Heat treatment is a controlled process of heating and cooling metals to alter their physical and mechanical properties without changing the product shape. The most common heat treatment methods for hardening are:

● Quenching: Heating the metal to a high temperature and then rapidly cooling it in water, oil, or air to trap certain microstructures, such as martensite in steel, which are harder and stronger.

● Tempering: Often performed after quenching, tempering involves heating the material to a temperature below the critical point to reduce brittleness while maintaining the increased hardness.

Alloying

Alloying involves adding other elements to a base metal to improve its properties. For example, adding carbon to iron creates steel, which can be hardened significantly more than pure iron. Other alloying elements like chromium, nickel, and molybdenum can also enhance hardenability. The key difference between alloying and heat treatment is that alloying is a permanent change to the material's composition, while heat treatment is a reversible change to its microstructure.

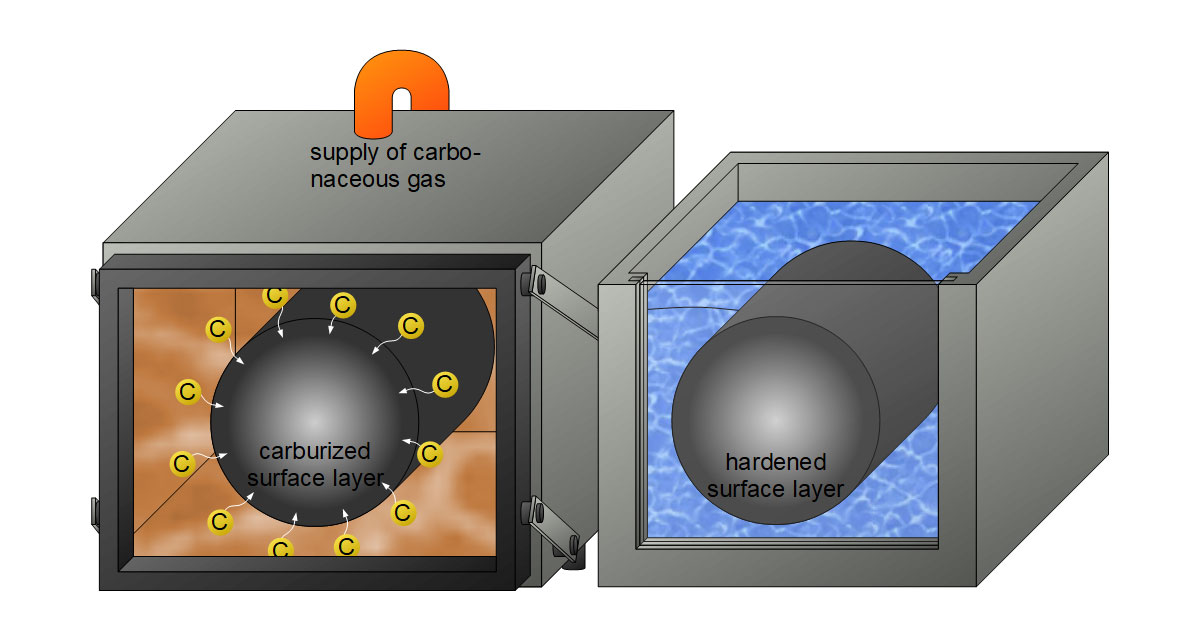

Case Hardening

Case hardening is a process that hardens the surface of metal while allowing the metal beneath to remain soft, thus creating a thin layer of harder metal at the surface called the "case." Techniques include:

● Carburizing: Adding carbon to the surface layer of low-carbon steel at high temperatures.

● Nitriding: Introducing nitrogen into the surface of steel to form a hard nitride layer.

Case Hardening Metals

Image Source: Double Stone Steel

Methods to Alter Surface Smoothness

Bead Blasting

Bead blasting is a surface finishing technique that enhances the smoothness of 3D printed metal parts. It involves propelling a stream of abrasive bead materials against the surface of a part under high pressure. This process not only improves the aesthetic appeal of the part but also contributes to its functional performance.

Bead blasting is performed using a variety of bead materials, such as glass, ceramic, or plastic. The choice of material depends on the desired finish and the material of the part being blasted.

Benefits of Bead Blasting

● Improved Surface Finish: Bead blasting smooths out the layer lines and imperfections, resulting in a uniform matte finish.

● Enhanced Paint Adhesion: The process creates a surface that is more conducive to paint or coating adhesion.

● Deburring: It effectively removes burrs and sharp edges, which is crucial for part safety and functionality.

● Cleaning: Bead blasting cleans the surface from contaminants, which is essential for parts used in sensitive applications.

Image Source: AT Machining

Tumbling

Tumbling, also known as barrel finishing, is a post-processing technique used to improve the surface finish of 3D printed metal parts efficiently. This process is essential for applications that require a high-quality surface with reduced roughness and enhanced aesthetic appeal.

Tumbling involves placing 3D printed parts in a barrel or container along with abrasive media, such as ceramic pellets, steel pins, or natural media like walnut shells. The barrel is then rotated, causing the media to slide past the parts, effectively smoothing and polishing their surfaces.

Benefits of Tumbling

● Uniform Finish: Tumbling provides a consistent finish over the entire part, including hard-to-reach areas.

● Versatility: Different media types can be used to achieve various finishes, from matte to high gloss.

● Deburring: It effectively removes burrs and rounds off sharp edges, which is crucial for safety and assembly.

● Efficiency: Tumbling can process many parts simultaneously, making it a time-saving option for batch finishing.

Image Source: INOVATEC MACHINERY

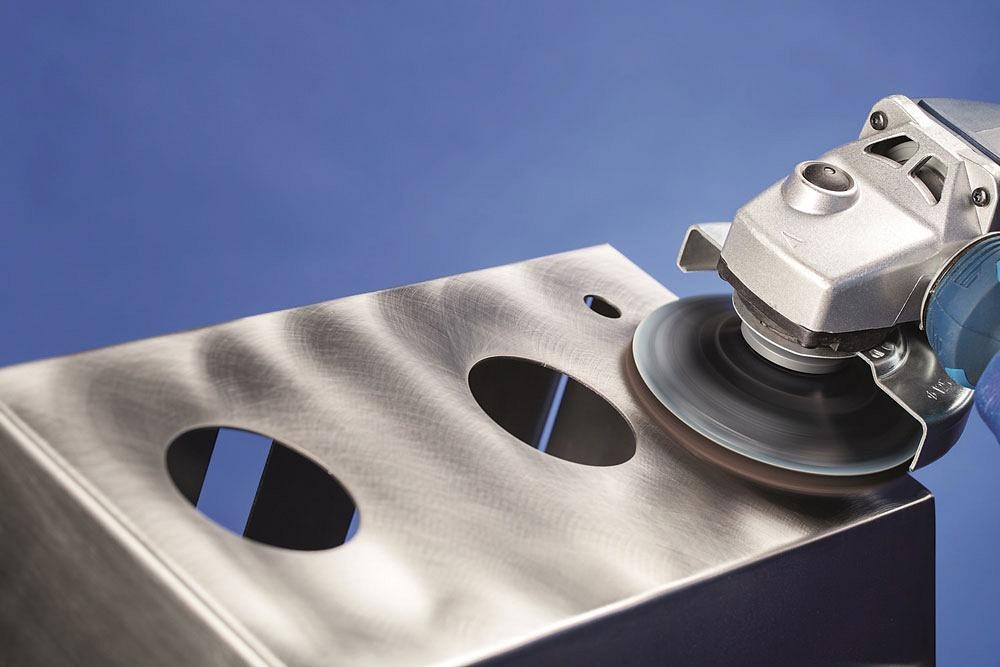

Brushing

Brushing is a cost-effective and straightforward method for deburring. It involves using a brush with wire bristles to remove surface irregularities and improve the overall texture of the part.

Benefits of Brushing

● Accessibility: Brushing can reach into recesses and intricate geometries that other finishing methods might miss.

● Flexibility: Different brush materials and stiffness levels can be used to achieve various finishes, from light cleaning to aggressive material removal.

● Deburring: It is particularly effective at deburring, ensuring that parts are safe to handle and fit for purpose.

● Surface Preparation: Brushing can prepare the surface for subsequent finishing processes, such as painting or coating.

Image Source: RAPID DIRECT

Methods to Alter Surface Finish Color While Improving Mechanical Properties

Spary Painting

Spray painting involves applying a coat of paint in a fine mist, ensuring a uniform and smooth finish every time.

Benefits of Spray Painting

● Aesthetic Enhancement: Spray painting can significantly improve the visual appeal of a part with a wide range of color options.

● Surface Protection: The paint layer provides additional protection against corrosion, wear, and environmental factors.

● Improved Mechanical Properties: Certain types of paint can add to the part’s structural integrity, making it more durable.

Spray Painting Stainless Steel SS316L Parts at 3DSPRO

Thermal Barrier Coating

Thermal barrier coatings (TBCs) are advanced materials systems usually applied to metallic surfaces operating at elevated temperatures, such as gas turbine or aero-engine parts. These coatings insulate components from large and prolonged heat loads by providing a layer of thermal resistance.

Benefits of Thermal Barrier Coatings

● Temperature Reduction: TBCs can reduce the surface temperature of the coated part by hundreds of degrees, extending the life of the part.

● Improved Efficiency: TBCs can improve the efficiency of engines and turbines by allowing parts to operate at higher temperatures without compromising their integrity.

● Enhanced Mechanical Properties: TBCs provide excellent thermal shock resistance and can help prevent oxidation and corrosion of the underlying metal.

● Color Alteration: While the primary function of TBCs is to provide thermal protection, they can also be used to alter the color of the part’s surface. The ceramic materials used in TBCs can be pigmented to achieve a range of colors, which can be beneficial for coding parts or enhancing their aesthetic appearance.

Image Source: Metallisation

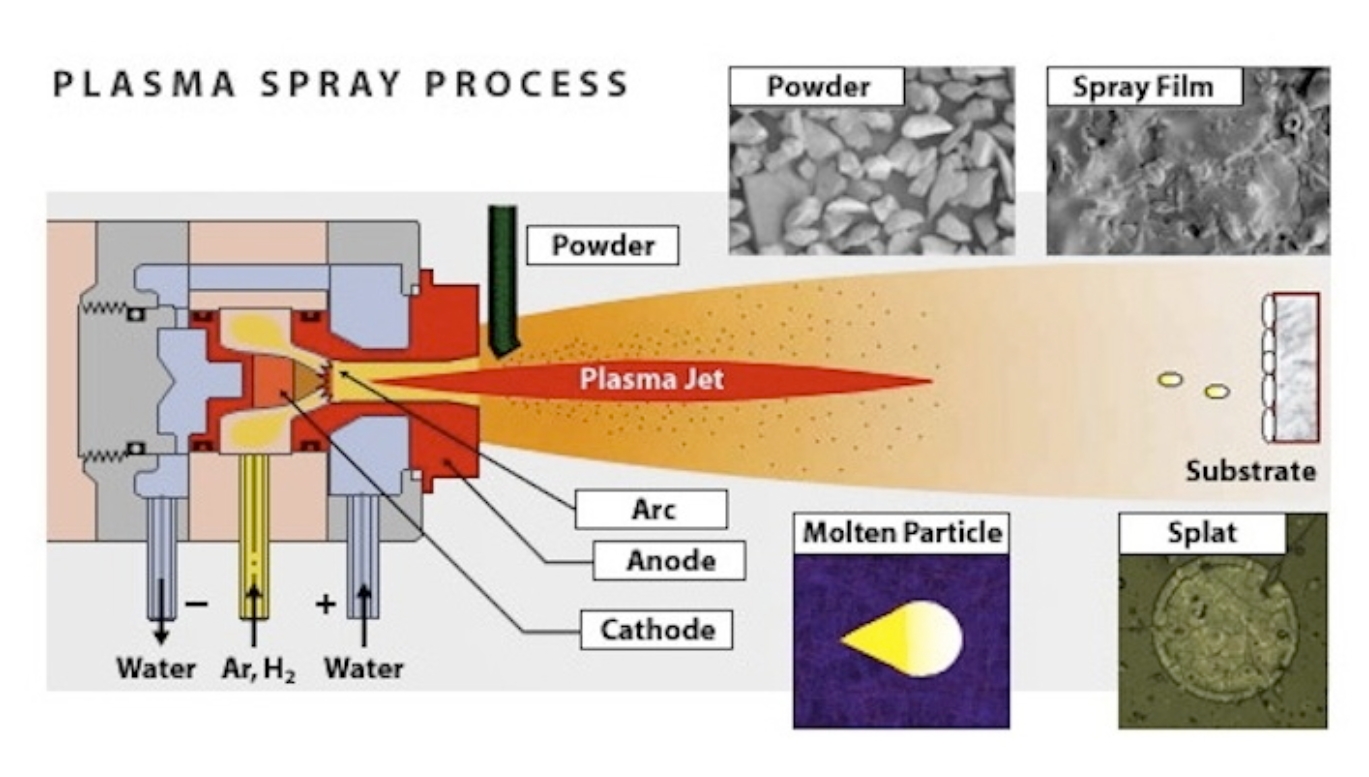

Plasma Spray Coating

Plasma spray coating is a surface treatment process that applies a protective layer to 3D-printed metal parts, enhancing both their aesthetic appeal and mechanical properties. It uses a plasma torch to melt powdered coating material, which is then sprayed onto the part’s surface.

Benefits of Plasma Spray Coating

● Enhanced Durability: The coating provides excellent wear and corrosion resistance, extending the lifespan of the part.

● Improved Performance: Coatings can be engineered to improve thermal and electrical properties, making them suitable for high-performance applications.

● Aesthetic Versatility: Different coating materials can achieve a wide range of colors, allowing for customization of the part’s appearance.

Image Source: Science Learning Hub

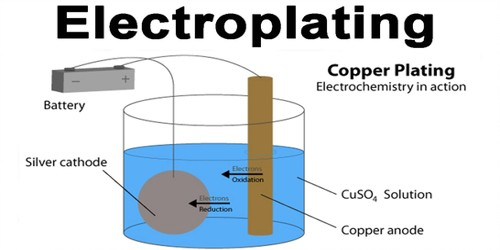

Electroplating

Electroplating involves the deposition of a thin, meticulously controlled layer of metal onto the surface of a part using an electric current.

Benefits of Electroplating

● Improved Wear Resistance: The metal coating, a key outcome of electroplating, can significantly increase the part’s resistance to abrasion and wear, thereby extending its lifespan and reducing maintenance costs.

● Enhanced Corrosion Protection: Electroplating can prevent oxidation and corrosion, particularly when using metals like nickel or chromium.

● Aesthetic Appeal: Electroplating can provide a shiny, reflective surface or a variety of colors depending on the metal used.

● Increased Strength: The added metal layer can contribute to the overall strength and durability of the part.

Image Source: RAPID DIRECT

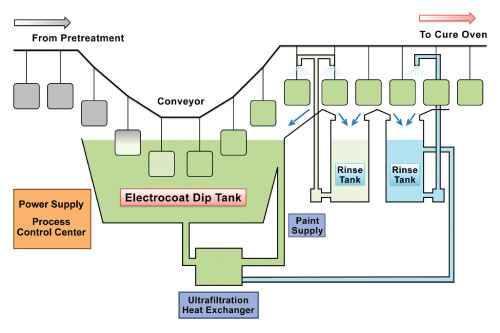

Electrocoating

Electrocoating, also known as e-coating or electrophoretic deposition, is a process that uses electrical current to deposit a paint or coating onto a part’s surface. This method is particularly effective for complex and intricate 3D-printed metal parts.

Benefits of Electrocoating

● Uniform Coverage: Electrocoating provides an even, consistent coating, even on parts with complex geometries.

● Enhanced Durability: The coating is resistant to chipping, corrosion, and UV damage, which improves the part’s mechanical properties.

● Color Customization: A wide range of colors can be achieved, allowing for aesthetic customization of the parts.

● Environmentally Friendly: Electrocoating uses less energy and produces less waste compared to other coating methods.

Image Source: AEROSPACE MANUFACTURING and DESIGN

Powder Coating

Powder coating involves applying a dry powder to the surface of the part, which is then cured under heat to form a skin-like layer.

Benefits of Powder Coating

● Durability: Powder coating creates a hard finish that is tougher than conventional paint, making it resistant to scratching, chipping, and wear.

● Uniform Finish: The electrostatic application ensures a consistent coating without drips or runs.

● Color Variety: A wide range of colors and textures is available, allowing for complete customization of the part’s appearance.

● Environmental Safety: Powder coating is an environmentally friendly process as it contains no solvents and emits minimal volatile organic compounds (VOCs).

Image Source: POWDERWERX

Anodizing

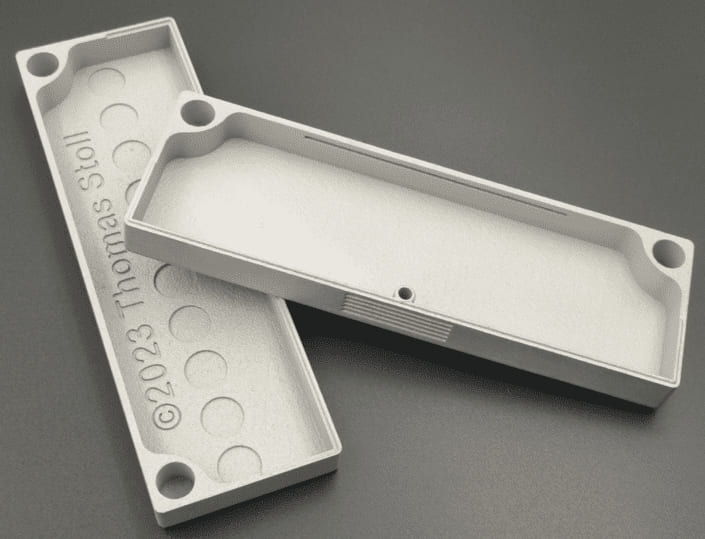

Anodizing is a surface finishing process that enhances the natural oxide layer on metal parts, particularly aluminum.

Benefits of Anodizing

● Improved Corrosion Resistance: The anodized layer protects the part from oxidation and environmental damage.

● Increased Wear Resistance: Anodizing hardens the surface, making it more resistant to scratches and wear.

● Enhanced Aesthetics: A wide range of colors can be achieved through dyeing, allowing for customization and branding.

● Electrical Insulation: The anodized layer can act as an insulator, which is beneficial for electronic components.

Image Source: Monster Builder

Methods to Alter Surface Roughness

Polishing

Polishing involves using various techniques to smooth the surface, thereby reducing roughness and enhancing the part’s aesthetic and functional qualities.

Benefits of Polishing

● Improved Surface Quality: Polishing reduces surface roughness, resulting in a smoother and more visually appealing finish.

● Enhanced Mechanical Properties: A polished surface can improve fatigue resistance by removing stress risers and micro-cracks.

● Increased Corrosion Resistance: Smoothing the surface can reduce the likelihood of corrosion initiation points.

Image Source: Markham Metals

Electropolishing

Electropolishing is a process that refines the surface of metal parts, enhancing their aesthetic and functional properties. It is particularly beneficial for 3D-printed metal parts, which may have surface irregularities due to the layer-by-layer construction process.

Benefits of Electropolishing

● Super Smoothness: Electropolishing can significantly reduce surface roughness, achieving a higher level of smoothness than many mechanical finishing methods.

● Complex Geometries: The process can polish parts with complex or irregular shapes, reaching areas that are inaccessible to other finishing methods.

● Corrosion Resistance: A smoother surface means fewer places for corrosive elements to take hold, potentially extending the life of the part.

● Consistent Finish: Electropolishing generally delivers a more consistent finish across the entire part surface without leaving marks or patterns.

Image Source: Cougartron

Methods to Assemble Large 3D Printed Metals

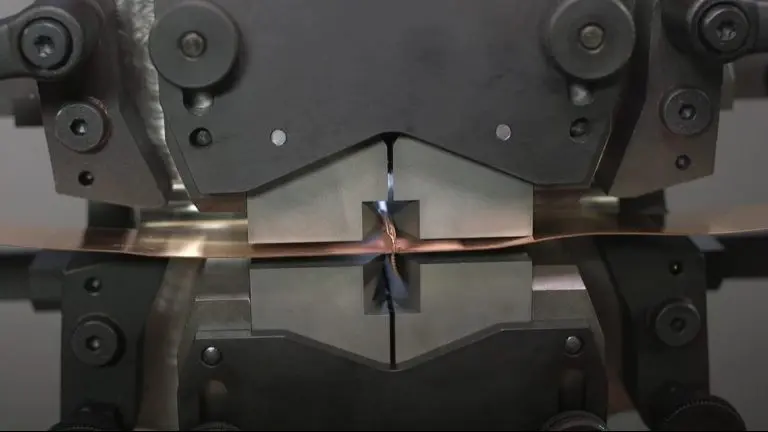

Cold Welding

Cold welding, also known as contact welding, is a solid-state welding process that joins two or more metal parts without the application of heat. This technique is particularly useful for assembling large 3D-printed metal parts where traditional welding methods might be challenging.

Benefits of Cold Welding

● No Heat Affected Zone (HAZ): Since no heat is applied, there is no risk of altering the mechanical properties of the parts due to thermal effects.

● Material Compatibility: Cold welding can be used to join dissimilar metals that may be incompatible with other welding techniques.

● Precision: The process allows for precise control over the joint, making it ideal for complex assemblies.

● Clean and Eco-Friendly: Cold welding produces no fumes, spatter, or radiation, making it a clean and environmentally-friendly process.

Image Source: Fractory

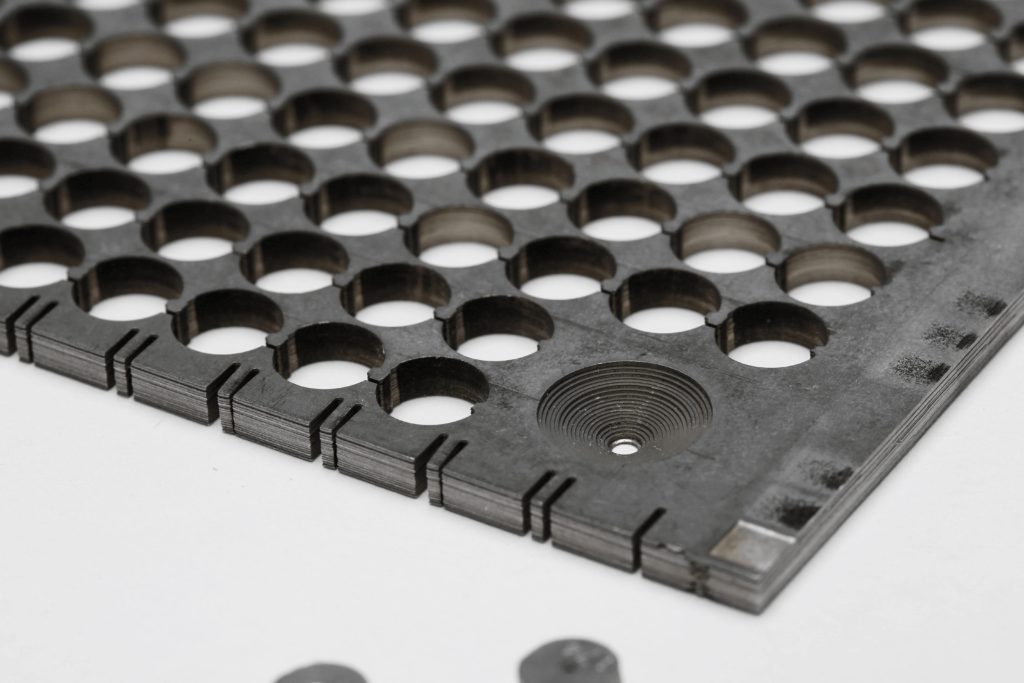

Diffusion Bonding

Diffusion bonding is a solid-state joining process that creates a bond between two surfaces at the atomic level.

Benefits of Diffusion Bonding

● Strength: The joint created by diffusion bonding is typically as strong as the parent material, providing excellent structural integrity.

● Precision: This method allows for the joining of complex and intricate shapes with high dimensional accuracy.

● Material Versatility: Diffusion bonding can be used with a wide range of metals and alloys, including those that are difficult to weld using conventional methods.

● Cleanliness: The process does not introduce contaminants or additional materials, such as filler metals, ensuring the purity of the assembly.

Image Source: FOTOFAB

3DSPRO SLM 3D Printing Services

At 3DSPRO, we specialize in Selective Laser Melting (SLM) 3D printing services, offering cutting-edge solutions to turn your innovative ideas into high-quality metal parts.

We offer:

● AI-powered Instant Quoting System: Begin by uploading your 3D model to our platform. We support mainstream 3D formats, ensuring a seamless transition from design to production.

● Customization: Tailor your project with our customization options. Choose from a variety of metals, including titanium, stainless steel, and aluminum, to match the specific needs of your application.

● Rapid Production & Delivery: With an average production time of just 17.5 hours and expedited shipping options, you'll have your parts within days, not weeks.

● Diverse Surface Finishing Choices: We offer more than ten surface finishing options to enhance the final performance of your parts, including tumbling, polishing, spray painting, powder coating, electroplating, electrocoating, anodizing, etc.

You'll get:

● Economical Pricing for Every Scale: At 3DSPRO, we understand the importance of cost-efficiency for your projects. Whether you're printing a single prototype or gearing up for mass production, our pricing model is designed to be budget-friendly. We ensure that even individual part production is economically viable, providing you with affordable unit prices without compromising on quality.

● High-quality and Precise Parts: Our SLM printing tolerance is 0.5%mm, resulting in parts with exceptional detail and accuracy. SLM-produced parts feature superior mechanical properties It is ideal for functional prototypes and end-use applications in demanding environments.

● Efficient Innovation: Leverage our SLM services to produce complex designs that are difficult or impossible to create using traditional manufacturing methods.

Our Commitment to Quality

At 3DSPRO, our one-stop service matches all types of quality and quantity requirements at every stage of product development. You get exactly what you imagined—a perfect realization of your creative vision, backed by our professional warranty.

COMMENTS

- Be the first to share your thoughts!