Resin 3D printing is a perfect solution for miniatures, jewelry, dental models, and functional prototypes. However, anyone who has tried resin printing at home knows the process can be unforgiving. Failed prints, sticky surfaces, or warped parts are common frustrations that waste time, resin, and energy.

Professional 3D printing services exist to eliminate these headaches. By combining technical expertise, industrial-grade equipment, and strict quality control, they deliver consistent results that hobbyists and businesses alike can rely on. Let’s explore the most common resin 3D printing problems and when to choose resin 3D printing services.

Problem 1: Print Failures and Layer Separation

The Issue

One of the most frequent frustrations is when a print detaches from the build plate or layers peel apart mid-print. Causes include:

• Incorrect exposure times

• Poor build plate leveling

• Resin contamination or insufficient adhesion

The Consequences

Incomplete or warped parts, wasted resin, and hours lost.

How to Prevent

• Calibrated printers with dialed-in exposure settings for each resin type.

• Regular build plate maintenance and leveling checks.

• Resin filtering and tank inspections before every job.

• Pre-print simulations to predict adhesion risks.

Problem 2: Supports and Surface Quality

The Issue

Supports are essential in resin printing, but poor placement can ruin a model. Too few supports cause collapse; too many leave scars on delicate surfaces.

The Consequences

Fragile prints, visible blemishes, and excessive post-processing.

How to Prevent

• Expert orientation and support design using advanced software

• Hybrid approach: automated support generation plus manual refinement

• Careful removal and finishing techniques to minimize scarring

• Orientation strategies that balance strength with surface aesthetics

Problem 3: Warping, Shrinkage, and Dimensional Inaccuracy

The Issue

Resin naturally shrinks as it cures. Without compensation, parts may warp, distort, or fail to meet dimensional tolerances.

The Consequences

Misfitting components, unusable prototypes, and unreliable results for precision applications like dental or engineering.

How to Prevent

• Controlled print environments with stable temperature and humidity

• Resin-specific compensation factors are built into slicing profiles

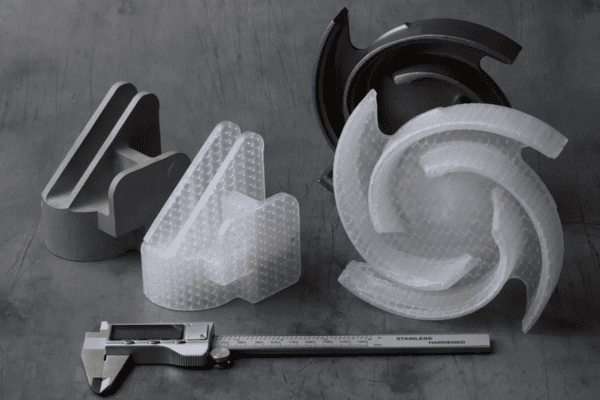

• Dimensional QA checks with calipers or 3D scanning

• Iterative testing to ensure accuracy across batches

Problem 4: Print Contamination and Resin Handling

The Issue

Dust, cured resin fragments, or improperly stored resin can compromise print quality.

The Consequences

Rough surfaces, failed adhesion, or inconsistent curing.

How to Prevent

• Resin filtration between every print

• Sealed, climate-controlled resin storage

• Strict handling protocols to avoid contamination

• Regular tank cleaning and inspection

Problem 5: Post-Processing Challenges

The Issue

Washing and curing are critical steps, but they’re easy to get wrong. Under-cured parts remain sticky; over-cured parts become brittle.

The Consequences

Fragile, unattractive, or dimensionally unstable parts.

How to Prevent

• Industrial wash and cure stations with consistent cycles

• Resin-specific curing profiles for optimal strength and finish

• Professional finishing techniques (sanding, polishing, painting)

• Quality checks to ensure parts meet both functional and aesthetic standards

When to Choose a Service vs. DIY

Resin 3D printing at home is rewarding for experimentation, small personal projects, or learning the craft. But when precision, reliability, or time-to-market matters, professional services are the smarter choice.

DIY is best for:

• Hobby projects and one-off experiments

• Learning resin printing fundamentals

• Low-stakes parts where failure is acceptable

Services are best for:

• High-value prototypes or production parts

• Precision applications (dental, jewelry, engineering)

• Large or complex projects where failure is costly

• Businesses that need consistent, repeatable results

3DSPRO’s Resin 3D Printing Services

At 3DSPRO, we specialize in delivering professional-grade resin prints using three leading technologies:

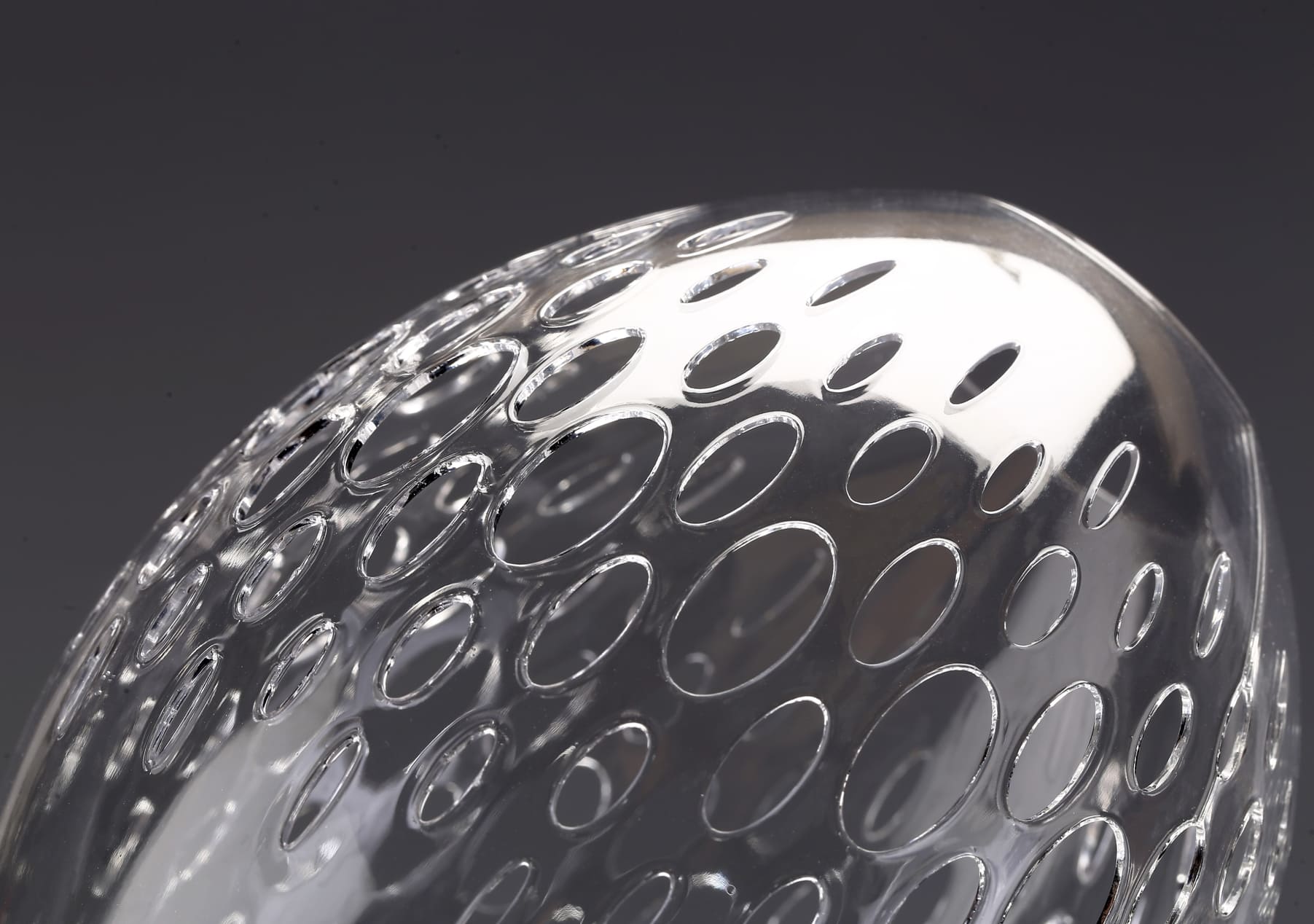

• SLA (Stereolithography): Exceptional accuracy and smooth surfaces, ideal for prototypes and models.

• LCD (Masked Stereolithography): High-quality, fast, and versatile for small-batch production.

• DLP (Digital Light Processing): High-speed printing with excellent detail, perfect for jewelry and dental applications.

By combining these technologies with expert technicians, rigorous quality control, and optimized workflows, we ensure your parts meet the highest standard.

Image Copyright © 3DSPRO Limited. All rights reserved.

COMMENTS

- Be the first to share your thoughts!