Manufacturing is undergoing a profound transformation. Traditional methods like injection molding and CNC machining have long dominated the production landscape, but they come with limitations, especially when it comes to flexibility, cost, and speed for small-batch runs.

Enter Multi Jet Fusion (MJF), HP’s breakthrough additive manufacturing technology. Once considered primarily for prototyping, MJF is now being adopted as a serious production method for low-volume manufacturing. Its ability to deliver high-quality, functional parts at speed, without the burden of tooling, makes it a compelling alternative for industries under pressure to innovate faster and at lower cost.

The Shift Toward Low-Volume Production

The global manufacturing environment is changing, and several forces are driving the shift toward low-volume production:

• Shorter Product Life Cycles: Consumer demand evolves rapidly, making long tooling lead times impractical.

• Customization and Personalization: From medical devices to consumer goods, customers expect tailored solutions.

• Cost Pressures: Tooling for injection molding can cost tens of thousands of dollars, which is hard to justify for small runs.

• Supply Chain Resilience: On-demand, localized production reduces dependency on global logistics.

Industries such as automotive, healthcare, aerospace, and consumer products are leading the charge, using low-volume production to test markets, deliver custom solutions, and reduce risk.

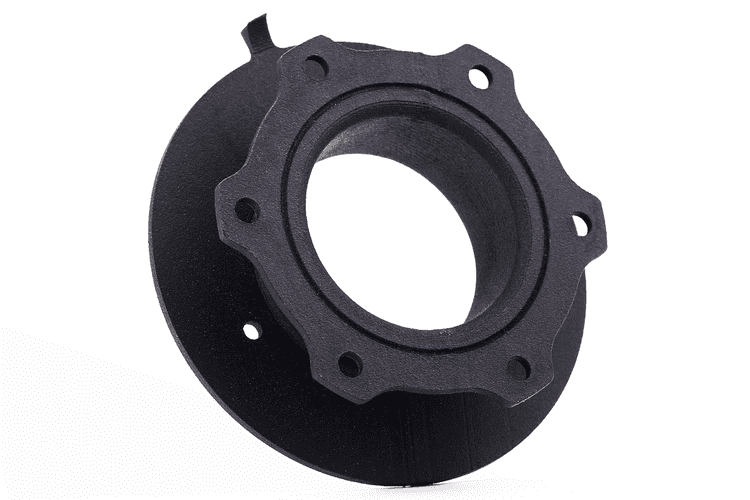

Image Copyright © 3DSPRO Limited. All rights reserved.

Why Manufacturers Are Choosing MJF

1. Cost Efficiency and Tooling Elimination

• No Upfront Tooling Costs: Traditional injection molding requires expensive steel or aluminum molds, often costing tens of thousands of dollars. For small runs, this cost is prohibitive. MJF eliminates tooling entirely.

• Lower Breakeven Point: MJF becomes cost-effective at volumes ranging from dozens to a few thousand parts, where injection molding would still be in the red.

• Iterative Savings: Because there’s no tooling, design changes don’t trigger new mold costs—manufacturers can update parts on the fly.

2. Speed to Market

• Rapid Turnaround: MJF can deliver production-ready parts in days, compared to weeks or months for tooling and machining.

• Agility in Product Launches: Companies can test markets with small batches, refine designs, and scale only when demand is proven.

• Bridge Manufacturing: MJF fills the gap between prototype and mass production, ensuring companies don’t lose momentum waiting for molds.

3. Design Freedom and Functional Integration

• Complex Geometries: MJF supports lattice structures, internal channels, and organic shapes that are impossible or costly with CNC or molding.

• Part Consolidation: Multiple components can be merged into a single printed part, reducing assembly time and potential failure points.

• Lightweighting: Optimized designs reduce material usage while maintaining strength, critical in aerospace and automotive.

4. Consistency, Accuracy, and Repeatability

• Isotropic Properties: Unlike many 3D printing methods, MJF produces parts with consistent strength in all directions.

• Dimensional Accuracy: Tolerances are tight enough for functional assemblies, making MJF viable for end-use parts.

• Batch Reliability: Manufacturers can trust that parts from one build will match the next, a key requirement for production.

5. Material Properties and Expanding Portfolio

• Durable Polymers: PA 12 and PA 11 are widely used for their toughness, chemical resistance, and stability.

• Specialty Materials: Flame-retardant, glass-filled, and flexible TPU options are expanding MJF’s reach into regulated industries.

• Application-Specific Performance: From impact resistance in automotive to biocompatibility in healthcare, material innovation is broadening adoption.

6. Sustainability and Waste Reduction

• Powder Reuse: MJF reuses a high percentage of unfused powder, reducing waste compared to SLS.

• On-Demand Manufacturing: Reduces shipping and warehousing needs, lowering carbon footprint.

• Circular Economy Potential: As recycling streams for polymers improve, MJF aligns with sustainability goals.

Comparing MJF with Other Manufacturing Methods

|

Method |

Strengths |

Limitations |

Best Use Case |

|

Injection Molding |

Low per-part cost at scale, excellent surface finish |

High upfront tooling cost, long lead times |

Mass production (10,000+ parts) |

|

No tooling, good for prototypes |

Slower, less consistent surface finish |

Prototyping, small runs |

|

|

CNC Machining |

High precision, wide material range |

Material waste, costly for complex geometries |

Metal parts, tight tolerances |

|

MJF |

Fast, repeatable, cost-effective for low volumes |

Limited to polymers (for now), may need post-processing |

Low-volume production, functional parts |

Challenges and Considerations

Material Range

Currently focused on polymers, though composites and new materials are emerging.

Parts may require post-processing (e.g., bead blasting, dyeing, or coating) for aesthetics.

Scaling Up

For very high volumes, injection molding remains more cost-effective.

Learning Curve

Engineers and designers must adapt to design-for-additive principles to maximize benefits.

FAQs

Q: What industries benefit most from MJF?

A: Automotive, healthcare, aerospace, and consumer goods are leading adopters, especially where customization and speed are critical.

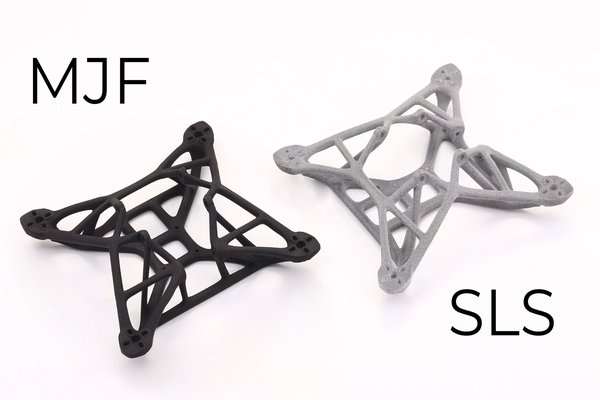

Q: How does MJF differ from SLS?

A: Both are powder-bed fusion technologies, but MJF uses fusing and detailing agents with infrared energy, resulting in faster builds, smoother surfaces, and more consistent mechanical properties.

Q: Is MJF suitable for end-use parts?

A: Yes. Unlike many 3D printing methods limited to prototyping, MJF produces strong, functional parts that can be used directly in production.

Q: Can MJF reduce costs compared to injection molding?

A: For low volumes, absolutely. By eliminating tooling, MJF often delivers significant cost savings and faster ROI.

Q: What materials are available for MJF?

A: The most common materials include:

• PA 12 (Nylon 12): Strong, versatile, and cost-effective for general applications.

• PA 11 (Nylon 11): More ductile and impact-resistant, ideal for living hinges and flexible parts.

• PA 12 Glass Beads: Reinforced with glass for higher stiffness and dimensional stability.

• TPU (Thermoplastic Polyurethane): Flexible, durable, and elastic, used for seals, gaskets, and footwear.

• Specialty Grades: Flame-retardant and ESD-safe materials are emerging for regulated industries.

Q: What post-processing is required for MJF parts?

A: Common steps include painting, dyeing, vapor smoothing, or coating. These improve surface finish, aesthetics, and sometimes performance.

COMMENTS

- Be the first to share your thoughts!