SLS 3D Printer Cost

Selective Laser Sintering (SLS) 3D printers represent a significant advancement in additive manufacturing, offering the ability to create complex and durable parts. When considering the cost of SLS 3D printers, it’s important to understand that prices can vary widely based on factors such as size, speed, precision, and the brand.

Entry-Level Desktop SLS 3D Printers

For those new to SLS printing or with limited budgets, desktop SLS 3D printers are accessible. Prices for these machines start at around $6,000, making them suitable for small businesses, educational institutions, and hobbyists. These printers typically offer a smaller build volume and may have slower print speeds but still maintain a high level of detail and part strength.

Mid-Range Desktop SLS 3D Printers

Mid-range models, like the Sinterit Lisa, are priced at approximately $13,990. They strike a balance between affordability and professional capabilities, and they are suitable for design studios and engineers who require higher precision and a larger build volume.

Professional Desktop SLS 3D Printers

Professional-grade printers, such as the Sinterit Lisa Pro, offer enhanced features like larger build volumes and improved precision. These models are priced at about $17,990, catering to professionals who need production-quality in a desktop package.

Industrial SLS 3D Printers

At the top end of the market are industrial SLS 3D printers. These systems offer the largest build volumes, fastest print speeds, and a wide range of material options. They are designed for high-volume production and can cost upwards of $100,000, depending on the specifications and capabilities required.

How does SLS 3D printer work?

Selective Laser Sintering (SLS) builds parts by fusing powdered material layer by layer with a laser:

1. Preparing the Powder Bed: The process starts with a thin layer of powder material—typically nylon or other thermoplastics—spread evenly across the build platform.

2. Sintering with Laser: A high-powered laser selectively fuses the powder particles in accordance with the cross-sectional area of the design. The laser’s path is dictated by a digital file, ensuring precise adherence to the model’s geometry.

3. Layering: After a layer is sintered, the build platform lowers, usually by about 0.1 mm, and a new layer of powder is applied on top.

4. Repeating the Process: The sintering and layering steps are repeated, building the object up one layer at a time.

5. Cooling and Extraction: Once printing is complete, the build chamber is left to cool, after which the finished parts are extracted from the loose powder.

6. Post-Processing: Excess powder is removed, often with compressed air, and parts may undergo additional post-processing like vibratory smoothing or dyeing to improve their surface finishes and properties.

Top SLS 3D Printers

1. Formlabs Fuse 1+ 30W

The Formlabs Fuse 1+ 30W is a benchtop SLS 3D printer that combines industrial-grade capabilities with user-friendly design. It’s engineered for speed, with a 30W laser that can complete a typical print job in just seven hours, and features a streamlined workflow from setup to finished parts. The printer supports a wide range of materials, offers remote monitoring, and utilizes Surface Armor technology for consistent results.

Image Source: Formlabs

2. Sintratec S3

The Sintratec S3 offers a high-power 30W laser for precision and speed. It’s part of the Sintratec All-Material Platform, which allows for around-the-clock printing with a focus on flexibility and efficiency. The S3’s Fusion Module and multiple Build Modules enable quick material changes and continuous operation.

Image Source: Sintratec

3. EOS FORMIGA P 110 Velocis

The EOS FORMIGA P 110 Velocis is an advanced industrial 3D printer that stands out for its precision, speed, and cost-efficiency. It’s designed for the production of small to medium-sized parts and is renowned for its ability to produce parts with consistent quality and fine detail. The printer operates with a CO₂ laser and has a build volume of 200 x 250 x 330 mm.

Image Source: EOS

4. 3D Systems SLS 380

The 3D Systems SLS 380 is an industrial-scale, process-controlled additive manufacturing solution designed for selective laser sintering. It offers high levels of throughput, consistency, performance, and yield, making it suitable for integrating into factory-floor ecosystems. The printer features closed-loop process controls for repeatability, a water-cooled laser, and a custom-developed algorithm that manages thermal uniformity within the build chamber. It captures over 100,000 thermal data samples per second to ensure dimensional stability and mechanical performance of parts.

Image Source: 3D Systems

5. Nexa3D QLS230

The Nexa3D QLS230 is a breakthrough in the SLS 3D printing market, offering an affordable yet powerful solution for industrial applications. It boasts a fast cycle time of just 24 hours, with a required cooling period of only 2 hours, thanks to its efficient 30-watt CO2 laser. The printer’s build volume is a versatile 230 x 230 x 230mm, and it supports a wide range of materials, including 10+ qualified nylon powders and patented metal powders.

Image Source: Nexa3D

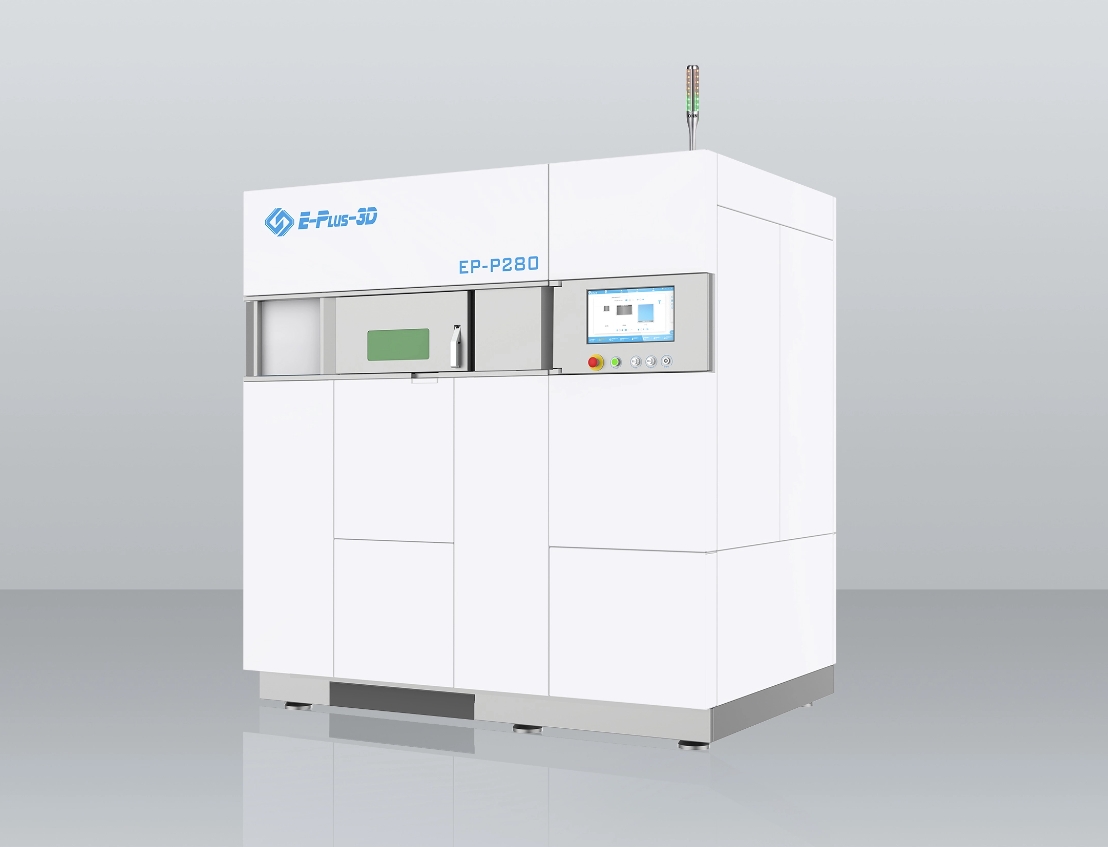

6. EPlus3D EP-P420

The EPlus3D EP-P420 is an innovative SLS 3D printer that utilizes polymer powder bed fusion (PPBF) technology to produce medium and large-sized parts. With a generous build cylinder of 420 x 420 x 465 mm, the EP-P420 is capable of printing customized products and small batch production efficiently. The EP-P420’s hardware and software are tailored to enhance the sintering process, reduce standby times, and ensure high-quality polymer parts.

Image Source: EPlus3D

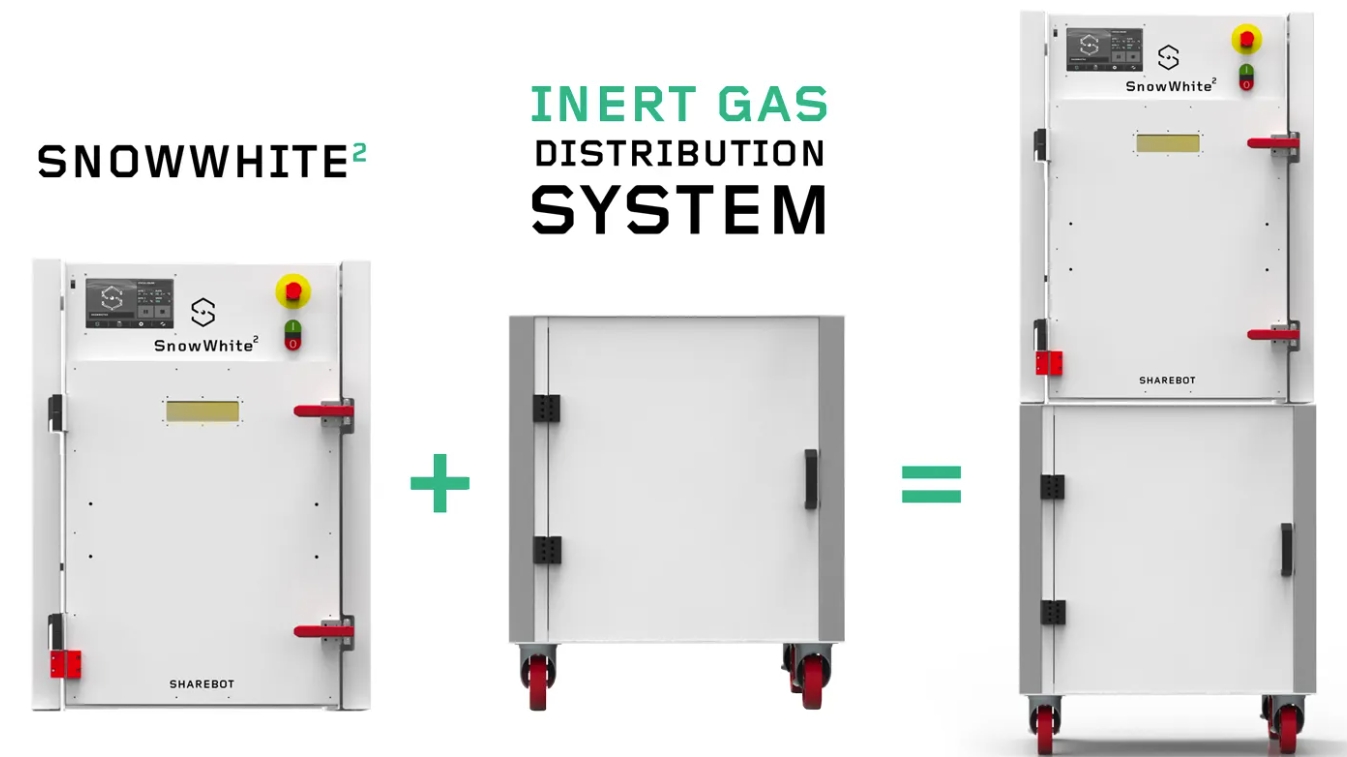

7. Sharebot SnowWhite 2

The Sharebot SnowWhite 2 is a professional SLS 3D printer that stands out for its compact size and precision. It’s equipped with a 14W CO2 laser and offers an optional nitrogen/argon modified atmosphere for advanced material handling. With a build volume of 100 x 100 x 100 mm and a layer resolution of 50 microns, it’s particularly suitable for universities and research centers focused on developing new polymers and composites. The SnowWhite 2 allows for quick start-up of print jobs, taking less than 15 minutes to begin printing, and requires only 300g of powder to start.

Image Source: Sharebot

8. XYZprinting MfgPro236 xS

The XYZprinting MfgPro236 xS is a versatile SLS 3D printer that caters to the needs of industrial users by offering a blend of performance, material range, and cost efficiency. It features a 60W CO2 laser that enhances its printing speed up to 22 mm per hour, and it supports a wide array of materials, including various grades of polyamide and TPU. The printer’s build volume is 230 x 230 x 250 mm. Equipped with intuitive software suites like Buildware and XYZprint AM SLS, the MfgPro236 xS simplifies the sintering process and allows for remote project management.

Image Source: XYZprinting

9. Prodways ProMaker P1000 X

The Prodways ProMaker P1000 X is an SLS 3D printer that offers a perfect blend of affordability, flexibility, and speed, making it suitable for the industrial production of series parts. It boasts a 300 x 300 x 360 mm build chamber and a 60W CO2 laser. The printer’s bi-directional counter-rotating roller system and 10-zone infrared heating system optimize mechanical properties and process repeatability across a wide range of materials. With a 24-point grid thermal control system, the P1000 X can achieve a build rate of 2 liters/hour at a layer thickness of 60/100/120 μm.

Image Source: Prodways

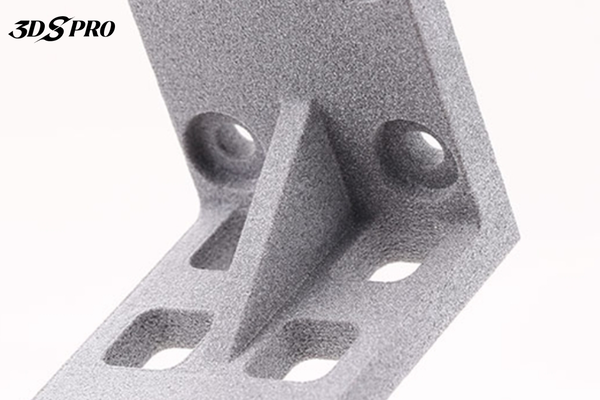

3DSPRO SLS 3D Printing Services

If you don't want to invest in a SLS 3D printer, 3DSPRO offers online SLS 3D printing services that delivers a seamless experience from digital design to physical parts.

You can upload your 3D models directly to our online quoting platform, receive an instant quote, and proceed with the printing process. Utilizing the latest in SLS technology, we provide high-quality prints with remarkable detail and strength. We are capable of handling a diverse range of materials, catering to various industry needs.

Moreover, we offer a suite of post-processing services to enhance the final product, including:

● Vapor Smoothing: By exposing the parts to a controlled vapor of a solvent, the surface layer melts slightly, smoothing out layer lines and imperfections.

● Vibratory Smoothing: By using vibrating machinery filled with abrasive media, this method gently polishes the parts, removing layer lines and imperfections.

● Spray Painting: A touch of color can be added with professional spray painting, providing a uniform coat that brings designs to life.

● Dyeing: For more vibrant and lasting color, we offer dyeing services that penetrate the entire part, ensuring color consistency throughout.

Every part produced by 3DSPRO goes through a rigorous quality control process to ensure that it meets the high standards expected by our clients. Our team of 3D printing experts is available to assist with any questions or custom requests, ensuring that clients receive the best possible outcome for their projects.

SLS 3D Printed Nylon Parts at 3DSPRO:

COMMENTS

- Be the first to share your thoughts!