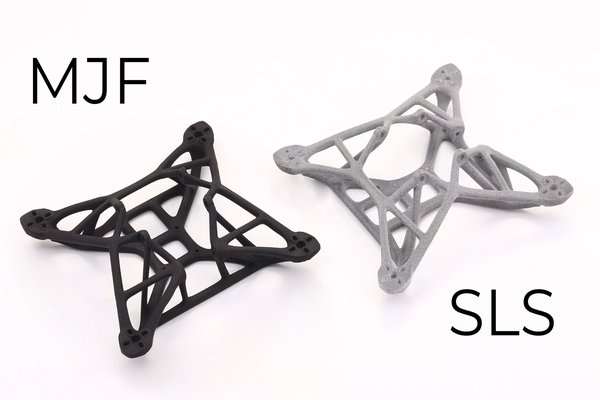

Powder-based 3D printing technologies, such as Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Selective Laser Melting (SLM), have transformed manufacturing by enabling complex geometries, rapid prototyping, and low-volume production. But before a printed part is ready for use, it must undergo a crucial post-processing step, depowdering.

Depowdering is a cleaning process that directly impacts part quality, safety, and production efficiency. In this article, we’ll explore what depowdering is, why it matters, how it’s done, the equipment involved, etc.

What is Depowdering?

Depowdering is the removal of unfused or unbound powder from a 3D printed part after the build process is complete.

In powder-based additive manufacturing, the build chamber is filled with fine powder material (nylon, metal, ceramic, etc.). The printer selectively fuses or binds particles layer by layer to form the part, while the surrounding powder acts as a support structure. Once printing finishes, the part is still buried in loose powder.

Depowdering involves:

• Extracting the part from the powder bed

• Removing excess powder from external and internal surfaces

• Recovering and recycling usable powder for future prints

Depowdering is essential for functional, aesthetic, and safety reasons, and it’s often the first stage in a broader post-processing workflow.

Image Copyright © 3DSPRO. All rights reserved.

Why Depowdering is Important?

Depowdering is a critical quality and safety step. Here’s why:

1. Dimensional Accuracy and Surface Quality

Residual powder can distort measurements, interfere with assembly, or create uneven surfaces. Proper depowdering ensures the part meets design tolerances.

2. Functional Performance

Powder trapped in internal channels can block airflow, fluid movement, or mechanical motion, especially in heat exchangers, manifolds, or medical devices.

3. Safety and Compliance

Fine powders, especially metals like titanium or aluminum, can be combustible or hazardous to inhale. Removing them reduces explosion risks and ensures compliance with workplace safety standards.

4. Powder Reuse and Cost Efficiency

Recovered powder can often be recycled into future builds, reducing material waste and lowering production costs.

5. Aesthetic and Customer Perception

For consumer-facing products, visible powder residue can make a part look unfinished or low-quality. Clean parts enhance brand reputation.

IImage Copyright © 3DSPRO. All rights reserved.

The Depowdering Process

While the exact workflow varies by technology and material, most depowdering processes follow these five key stages:

Step 1: Cooling the Printed Part

After printing, the build chamber and parts are often still hot. Cooling prevents warping and makes handling safer. Cooling times can range from a few hours to overnight, depending on material and build size.

Step 2: Bulk Powder Removal

The part is extracted from the build chamber, and the majority of loose powder is removed, often by shaking, brushing, or vacuuming. This step is typically done in a powder-handling enclosure to contain dust.

Step 3: Fine Powder Removal

For complex geometries, compressed air, vibration, or ultrasonic cleaning may be used to dislodge powder from small cavities and internal channels.

Step 4: Powder Recovery and Sieving

Collected powder is filtered to remove contaminants and oversized particles before being stored for reuse. Many facilities use automated sieving stations to maintain consistent powder quality.

Step 5: Final Inspection

The part is visually inspected (and sometimes scanned) to ensure no powder remains in critical areas before moving on to secondary post-processing like dyeing, coating, or machining.

Image Copyright © 3DSPRO. All rights reserved.

Depowdering Methods and Equipment

|

Method |

Description |

Best For |

Pros |

Cons |

|

Manual Brushing |

Hand tools to remove powder from surfaces |

Small batches, prototypes |

Low cost, flexible |

Labor-intensive, inconsistent |

|

Compressed Air Blasting |

High-pressure air dislodges powder |

Complex geometries |

Fast, effective |

Requires PPE, can waste powder |

|

Vacuum Extraction |

Industrial vacuums collect powder directly |

Medium to large parts |

Clean, reduces airborne dust |

Slower for intricate parts |

|

Vibratory Cleaning |

Parts placed in vibrating trays or tumblers |

Batch processing |

Consistent results |

May damage fragile parts |

|

Automated Depowdering Stations |

Enclosed systems with robotic arms, air jets, and sieves |

High-volume production |

Safe, efficient, repeatable |

High initial investment |

|

Ultrasonic Cleaning (for metals) |

Uses ultrasonic waves in liquid baths to remove powder |

Fine internal channels |

Extremely thorough |

Requires liquid handling and drying |

Image Copyright © 3DSPRO. All rights reserved.

Challenges and Innovations

Depowdering is evolving rapidly, but it still presents technical and operational challenges, especially as 3D printing moves toward mass production.

1. Complex Internal Geometries

Parts with lattice structures, deep channels, or blind holes can trap powder that’s nearly impossible to remove manually.

Innovation:

• Automated air-knife systems that direct high-velocity air into internal channels

• Rotational depowdering that spins parts to use gravity and vibration for powder removal

2. Powder Safety and Containment

Metal powders can be reactive, toxic, or explosive. Safe handling requires ATEX-rated equipment, proper ventilation, and strict PPE protocols.

Innovation:

• Fully enclosed depowdering stations with HEPA filtration

• Inert gas environments to prevent oxidation or combustion

3. Powder Quality Management

Recycled powder can degrade over time due to oxidation, contamination, or particle size changes.

Innovation:

• Automated sieving and blending systems that maintain a consistent particle size distribution

• Real-time powder monitoring using sensors and AI analytics

4. Labor and Throughput

Manual depowdering is slow and inconsistent, making it a bottleneck in production.

Innovation:

• Robotic depowdering arms that work continuously without fatigue.

• Integrated depowdering-printing systems that automate the entire workflow from build to clean part.

5. Sustainability

Powder waste and energy use are environmental concerns.

Innovation:

• High-efficiency powder recovery to reduce waste.

• Closed-loop systems that recycle nearly 100% of unused powder.

COMMENTS

- Be the first to share your thoughts!