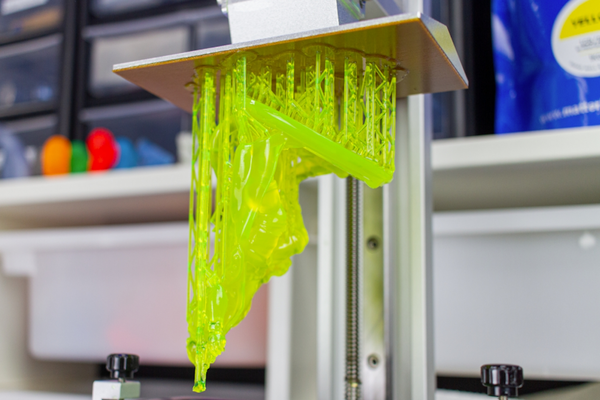

When nothing appears in your resin 3D printer, it can be frustrating. Here are some common reasons and troubleshooting steps to help you resolve the issue:

Check for Machine Malfunctions

1. First, ensure that the resin 3D printer itself is functioning correctly. Inspect the resin tank to see if there is any cured resin. If you find cured resin, it indicates that the machine is working properly, and the issue is likely due to human error.

2. Ensure the UV light source is functioning correctly. Perform an exposure test to see if the light is emitting properly.

3. If using an LCD or DLP printer, check if the screen is displaying correctly. A malfunctioning screen can prevent the resin from curing.

Leveling Issues with New Machines

For new machines, the problem might be related to leveling. Ensure that the contact plane and the printing platform are properly aligned and leveled.

Adjustments for Older Machines

1. If you have an older resin 3D printer and have yet to experience this problem before, try adjusting the model or changing the print direction or angle. Print a test piece to see if the problem persists. If it does, analyze the situation further as this may be caused by insufficient support structures.

2. Ensure that the model has adequate support. Inadequate support can lead to print failures.

3. Check the cleanliness and smoothness of the printing platform. Make sure the surface is clean. If there is any residue, the distance between the resin and the printing platform might be too large, preventing the resin from adhering properly after curing.

Resin Issues

1. Expired or contaminated resin. Ensure the resin is not expired or contaminated. Place a drop of resin under daylight to see if it cures. If it doesn't, consider replacing the resin.

2. Inappropriate resin storage temperature. Keep the resin at room temperature (around 20°C or 68°F) for optimal performance.

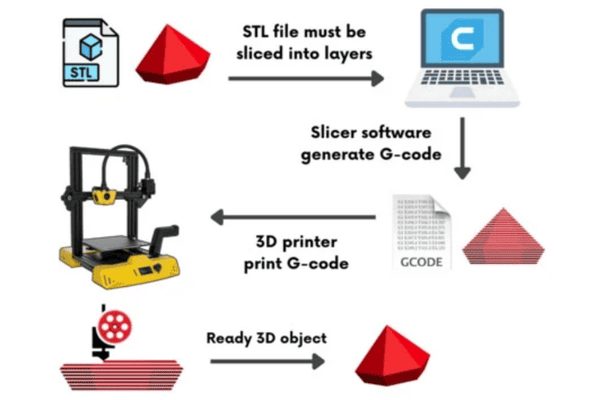

Slicer Settings

1. Increase the bottom layer exposure time by 10-20% to improve adhesion.

2. Adjust the number of bottom layers and the wait time before lifting the bottom layers, which can help in getting a stronger adhesion to the build plate.

By systematically checking these factors, you can often identify and resolve the problem that is preventing your resin 3D printer from printing. If the problem persists, it may be helpful to consult the printer's manual or contact the manufacturer for further assistance.

Successfully Printed and Painted Olympic Rings

COMMENTS

- Be the first to share your thoughts!