Among the many metal alloys available for 3D printing, stainless steels stand out for their balance of strength, corrosion resistance, and versatility. One particular grade, Stainless Steel 17-4 PH, has become a key material in industries ranging from aerospace to medical devices. Known for its precipitation-hardening properties, 17-4 PH combines high mechanical strength with excellent corrosion resistance, making it ideal for demanding environments.

In this article, we’ll explore what makes 17-4 PH unique, how it performs in Selective Laser Melting (SLM) 3D printing, its mechanical properties, applications, and pros and cons.

What is Stainless Steel 17-4 PH?

Stainless Steel 17-4 PH, also known as Type 630, is a precipitation-hardening martensitic stainless steel. Its name reflects its composition: approximately 17% chromium and 4% nickel, along with copper, niobium, and trace elements.

Key Characteristics:

• High strength and hardness: Achieved through heat treatment (precipitation hardening).

• Corrosion resistance: Comparable to other stainless steels, suitable for mildly corrosive environments.

• Heat treatability: Mechanical properties can be tuned by applying different heat treatment conditions (H900, H1025, etc.).

• Versatility: Used in aerospace, petrochemical, medical, and energy industries.

Unlike austenitic stainless steels such as 316L, 17-4 PH offers superior strength while maintaining good corrosion resistance, which makes it particularly attractive for parts that must withstand high stress and exposure to harsh conditions.

17-4 PH in SLM 3D Printing

Selective Laser Melting (SLM), also known as Laser Powder Bed Fusion (LPBF), is one of the most common processes for printing 17-4 PH. In SLM, a high-powered laser selectively melts layers of fine stainless steel powder to build complex geometries.

Why 17-4 PH Works Well in SLM:

• Near-wrought density: Printed parts can achieve >99% density, rivaling conventionally manufactured components.

• Dimensional stability: Maintains precision even after heat treatment.

• Complex geometries: Enable designs that are impossible with subtractive manufacturing.

• Surface finish: With optimized parameters, SLM delivers smooth surfaces suitable for functional parts.

SLM of 17-4 PH requires careful control of parameters to minimize residual stresses, porosity, and distortion. Post-processing steps such as heat treatment, machining, and polishing are often necessary to achieve final specifications.

Mechanical Properties of 3D Printed 17-4 PH

• Strength and hardness: Printed 17-4 PH offers high tensile strength and hardness, especially after heat treatment, which makes it suitable for load-bearing and high-stress applications.

• Corrosion resistance: Its resistance to corrosion is comparable to wrought stainless steels, allowing use in marine, chemical, and medical environments.

• Heat treatability: One of its standout features is the ability to tailor properties through heat treatment. Different conditions (like H900 or H1025) can adjust strength, hardness, and ductility to match specific needs.

• Density and integrity: With optimized printing parameters, parts can achieve near-full density, minimizing porosity and ensuring reliability.

• Microstructure: The fine martensitic structure formed during printing contributes to its strength, while precipitation hardening enhances toughness.

• Ductility: While strong, it is less ductile than austenitic stainless steels like 316L, meaning it sacrifices some flexibility for higher strength.

SLM 3D Printed Stainless Steel 17-4 PH Properties at 3DSPRO:

|

Properties |

Test Methods |

Parameters |

|

Hardness |

ASTM E18 |

38 HRC |

|

Relative Density |

ASTM B923 |

96.4% |

|

Tensile Strength |

ASTM E8 |

1230MPa |

|

Tensile Modulus |

ASTM E8 |

170GPa |

|

Elongation at Break |

ASTM E8 |

13% |

|

Yield Strength |

ASTM E8 |

1050MPa |

|

Corrosion |

ASTM F1089 |

PASS |

Applications of 3D Printed 17-4 PH

Aerospace

• Structural brackets and housings: Lightweight yet strong, reducing aircraft weight while maintaining reliability.

• Turbine blades and engine components: Withstand high temperatures and stresses, critical for propulsion systems.

Medical

• Surgical instruments: Corrosion-resistant tools that maintain sharpness and strength after repeated sterilization.

• Dental implants and orthodontic devices: Biocompatibility and mechanical strength make 17-4 PH suitable for long-term use.

• Custom prosthetics: Additive manufacturing allows patient-specific designs, improving comfort and functionality.

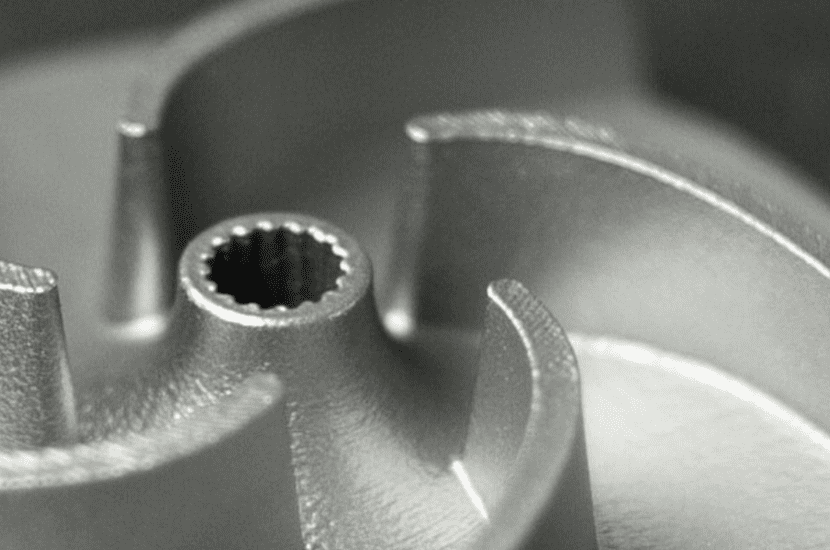

Energy

• Valves, pumps, and impellers: Operate in corrosive environments such as offshore platforms and chemical plants.

• Pipeline components: High strength and corrosion resistance extend service life in harsh conditions.

• Turbomachinery parts: Reliable under high stress and temperature, essential for power generation.

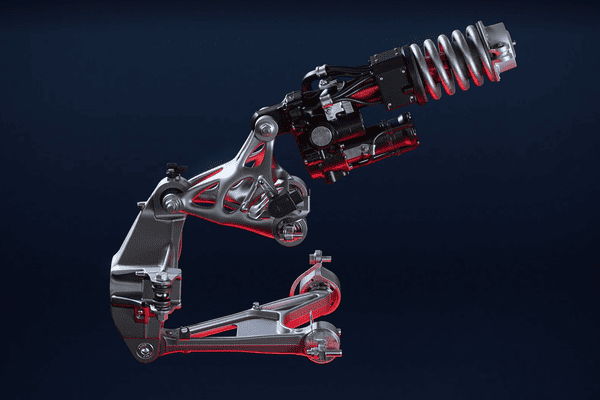

Automotive

• High-performance engine parts: Strong, heat-resistant components for racing and performance vehicles.

• Brackets, fasteners, and housings: Durable parts that withstand vibration and mechanical stress.

• Rail and marine applications: Corrosion resistance makes it suitable for coastal and humid environments.

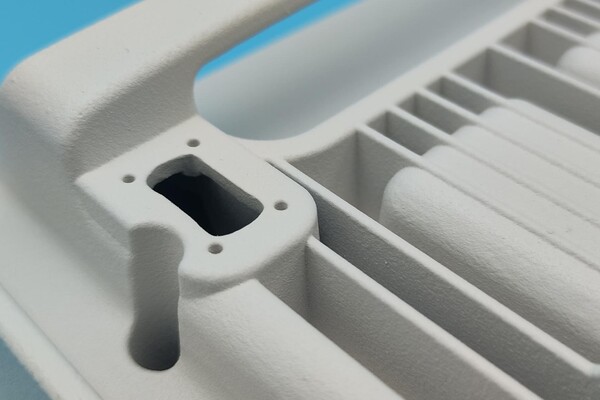

Industrial Equipment and Tooling

• Jigs and fixtures: Strong, durable tools for manufacturing environments.

• Custom tooling: Tailored designs reduce production time and improve precision.

• Wear-resistant components: Handles repetitive stress in industrial machinery.

Pros and Cons

|

Aspect |

Pros |

Cons |

|

Strength & Hardness |

High tensile strength and hardness, especially after heat treatment |

Less ductile than austenitic stainless steels (e.g., 316L) |

|

Corrosion Resistance |

Comparable to wrought stainless steels, suitable for marine and chemical environments |

Not as resistant as specialized alloys like duplex stainless steels |

|

Heat Treatability |

Properties can be tailored through precipitation hardening (H900, H1025, etc.) |

Requires careful heat treatment to avoid brittleness |

|

Density & Integrity |

Near-wrought density (>99%) achievable with optimized SLM parameters |

Residual stresses and porosity possible if parameters are not well controlled |

|

Design Freedom |

Enables complex geometries and lightweight structures not possible with traditional methods |

Surface finish may require polishing or machining for critical applications |

|

Cost & Accessibility |

High-performance material available through additive manufacturing services |

More expensive than common stainless steels like 304 or 316L |

|

Reliability |

Stable mechanical properties after post-processing, suitable for critical industries |

Post-processing (heat treatment, machining) adds time and cost |

3D Printing Stainless Steel 17-4 PH at 3DSPRO

At 3DSPRO, we deliver advanced Selective Laser Melting (SLM) 3D printing services designed for high-performance applications, specializing in materials like 17-4 PH stainless steel for exceptional strength, durability, and corrosion resistance. Our proprietary 3D Plus™ solution enhances precision, efficiency, and consistency across complex geometries, enabling clients to achieve production-ready parts with superior mechanical properties and surface quality. Whether for aerospace, medical, or industrial innovation, 3DSPRO combines cutting-edge technology with expert engineering to transform ideas into reliable, high-value components.

Upload 3D Files to 3D Print 17-4 PH Today >>

COMMENTS

- Be the first to share your thoughts!