Selective Laser Sintering (SLS) has long been recognized as one of the most versatile and industrially relevant additive manufacturing technologies. By using a laser to fuse powdered materials layer by layer, SLS enables the creation of strong, functional parts without the need for support structures.

While polyamide (nylon) has traditionally dominated the SLS landscape, recent advances have opened the door to new polymers with unique properties. Among these, polypropylene (PP) stands out for its chemical resistance, low density, and flexibility. Yet, neat polypropylene presents challenges in SLS: shrinkage, warpage, and limited mechanical strength often restrict its use. To overcome these limitations, researchers and manufacturers have developed glass-filled polypropylene (PP-GF) powders. By reinforcing PP with glass fibers or beads, the material gains enhanced stiffness, dimensional stability, and durability, making it suitable for demanding industrial applications.

Polypropylene in SLS 3D Printing

Polypropylene is one of the most widely used thermoplastics in traditional manufacturing. It is found in packaging, automotive components, consumer goods, and medical devices thanks to its:

• Chemical resistance against acids, bases, and solvents

• Low density, making it lighter than many other plastics

• Flexibility and toughness, allowing for living hinges and snap-fit designs

However, translating these advantages into SLS printing has historically been difficult. PP’s semi-crystalline nature leads to high shrinkage during cooling, which causes warpage and dimensional inaccuracies. Its relatively low melting point also narrows the sintering window, making process control more challenging.

What is Glass-Filled Polypropylene (PP GF)?

Glass-filled polypropylene is a composite material in which PP powder is reinforced with glass fibers or beads. The filler content typically ranges from 10% to 40%, depending on the desired balance between strength and processability.

• Glass fibers: Long or short fibers embedded in the polymer matrix. They provide high tensile strength and stiffness, but can make the material more brittle.

• Glass beads: Spherical particles that improve dimensional stability and reduce warpage. They are less aggressive on machine hardware compared to fibers.

The addition of glass fillers alters the material’s behavior during sintering. The glass acts as a stabilizer, reducing shrinkage and improving heat resistance. It also enhances load-bearing capacity, making PP-GF suitable for functional prototypes and end-use parts.

In short, PP-GF combines the chemical resistance and low density of polypropylene with the rigidity and dimensional accuracy of glass reinforcement.

Mechanical & Thermal Properties

• Strength and stiffness: PP-GF offers nearly double the tensile modulus of neat PP, making it suitable for load-bearing applications.

• Dimensional stability: Reduced shrinkage and warpage allow for more accurate parts, especially in larger builds.

• Thermal resistance: Higher heat deflection temperature enables use in environments where neat PP would deform.

• Trade-off in ductility: The addition of glass reduces elongation at break, meaning PP-GF is less flexible and more brittle than neat PP.

SLS 3D Printed Glass-Filled Polypropylene Properties at 3DSPRO:

|

Properties |

Methods |

Parameters |

|

Density |

DIN 53466 |

1.26 g/cm³ |

|

Heat Deformation (0.45 MPa) |

ASTM D648 |

179℃ |

|

Heat Deformation (1.8 MPa) |

ASTM D648 |

129℃ |

|

Tensile Strength |

ASTM D638 |

41MPa |

|

Tensile Modulus |

ASTM D638 |

2000MPa |

|

Elongation at Break |

ASTM D638 |

9% |

|

Flexural Strength |

ASTM D790 |

70MPa |

|

Flexural Modulus |

ASTM D790 |

2100MPa |

|

Notched Impact Strength |

ASTM D256 |

48 J/m |

|

Unnotched Impact Strength |

ASTM D256 |

240 J/m |

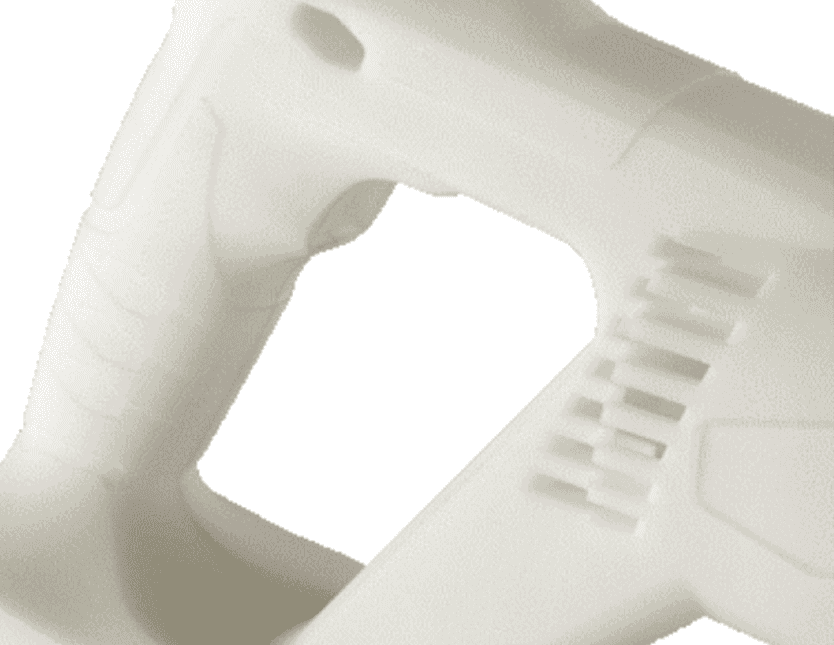

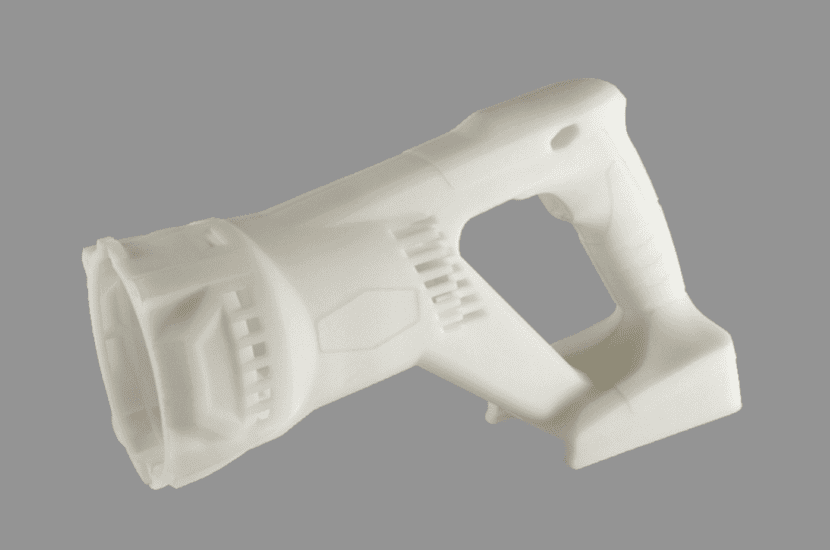

Applications of SLS 3D Printed PP-GF

The unique balance of properties makes PP-GF a strong candidate for various industries:

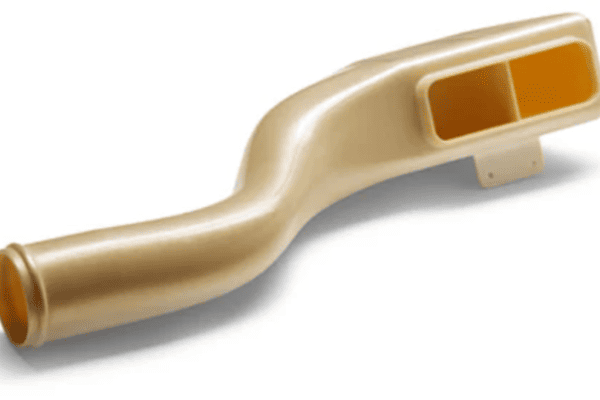

Automotive

• Brackets, housings, and clips requiring rigidity and chemical resistance

• Lightweight components that reduce overall vehicle mass

• Prototypes for fuel system parts where solvent resistance is critical

Medical

• Sterilizable surgical guides and reusable medical devices

• Components exposed to autoclave cycles thanks to improved heat resistance

• Chemical-resistant housings for diagnostic equipment

Industrial

• Jigs and fixtures that must withstand mechanical stress

• Fluid-handling parts exposed to aggressive chemicals

• Durable housings for sensors and electronics in harsh environments

Consumer Goods

• Functional prototypes of household items

• Snap-fit assemblies requiring dimensional accuracy

• Durable parts for appliances and tools

By combining lightweight design, chemical resistance, and improved stiffness, PP-GF enables SLS to move beyond prototyping into true production applications.

Pros and Cons

|

Pros |

Cons |

|

High stiffness and strength compared to neat PP |

Reduced ductility and impact resistance (more brittle) |

|

Excellent chemical resistance |

Abrasive fillers can increase wear on machine components |

|

Improved dimensional stability and reduced warpage |

Higher material cost compared to neat PP powders |

|

Higher heat deflection temperature |

Recycling challenges: mixed polymer-filler powders are harder to reuse efficiently |

3DSPRO SLS 3D Printing PP GF Service

At 3DSPRO, we believe that materials are the foundation of innovation. Choosing the right polymer can mean the difference between a prototype that merely demonstrates form and a finished part that performs reliably in the field. That’s why we’ve invested in specialized SLS capabilities for Glass-Filled Polypropylene (PP-GF), a material that blends chemical resistance, lightweight design, and enhanced stiffness.

We Have

• Precision SLS 3D Printing Service: Our equipment is calibrated specifically for PP-GF powders, ensuring consistent sintering and dimensional accuracy.

• Material Expertise: We understand the nuances of PP-GF, such as its sintering window, shrinkage behavior, and filler impact, and apply that knowledge to optimize every build.

• Design for Additive Manufacturing (DfAM) Support: Our engineers collaborate with you to adapt designs for PP-GF, maximizing strength while minimizing brittleness.

• Quality Assurance: Each part undergoes inspection for dimensional accuracy, mechanical performance, and surface finish.

We don’t just print parts; we help you transform ideas into durable, production-ready solutions. With PP-GF, your designs gain the strength and stability needed to thrive in real-world conditions, and with 3DSPRO, you gain a partner committed to accuracy, reliability, and innovation.

Use SLS 3D Printing Glass-Filled Polypropylene Service Today >>

COMMENTS

- Be the first to share your thoughts!