Metal 3D Printer Cost

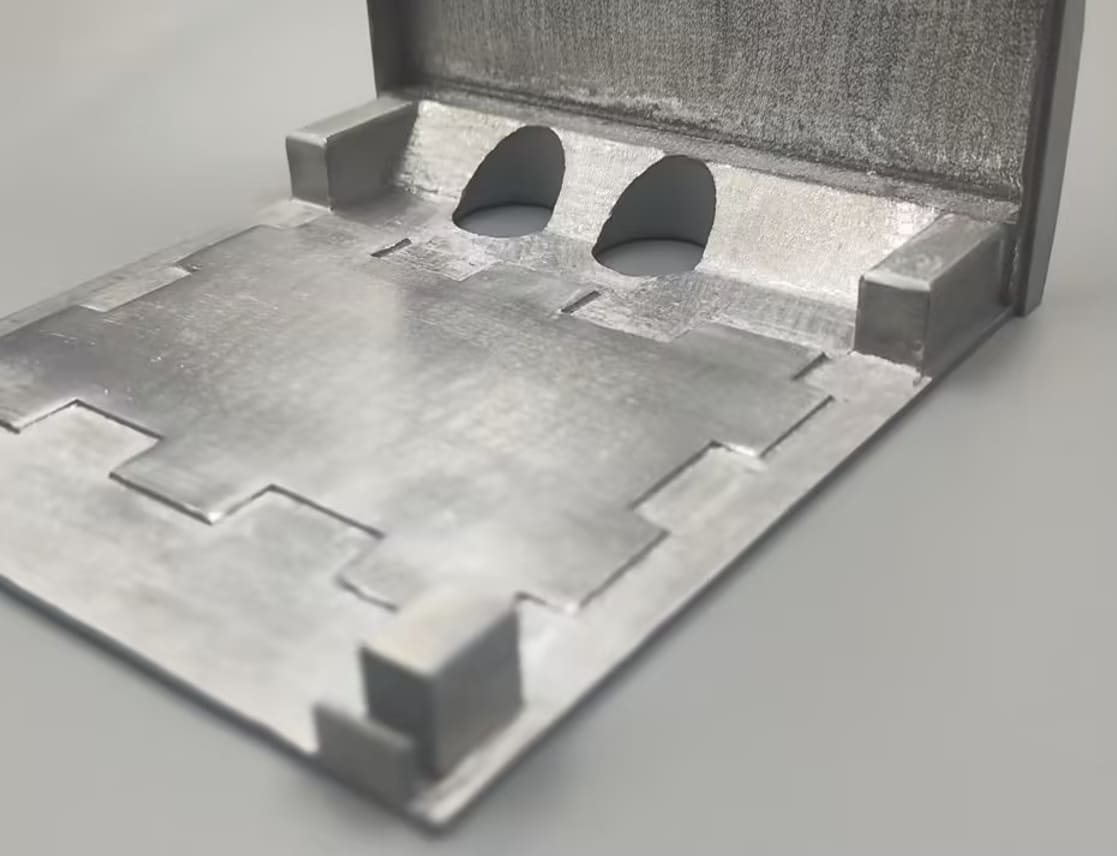

Investing in a metal 3D printer is a decision that can change your manufacturing process significantly. Understanding the metal 3D printer cost is crucial as it varies widely based on several factors.

The initial cost of metal 3D printers can range from $50,000 for entry-level systems to over $1 million for high-end industrial-grade printers. The price can be influenced by the printer’s build volume, laser power, precision, and automation features.

Beyond the purchase price, the total cost per piece for 3D printing metal typically ranges from $15 to $800, including the size and complexity of the model, finishing requirements, and the chosen printing technology.

Besides, there are hidden expenses such as machine maintenance, material costs, and the labor for post-processing. Machine time and finishing time are significant cost drivers.

For those not ready to commit to purchasing a machine, on-demand metal 3D printing services offer a cost-effective solution. These services allow you to pay for only what you need, when you need it, without the overhead of owning and maintaining a printer.

Image Source: Materialise

Types of Metal 3D Printers

Powder Bed Fusion (PBF)

Powder Bed Fusion printers, including Selective Laser Sintering (SLS), Selective Laser Melting (SLM), and Direct Metal Laser Sintering (DMLS), use a laser or electron beam to melt and fuse metal powder layer by layer.

Key Features of Powder Bed Fusion Metal 3D Printers:

● Precision: Capable of producing parts with complex geometries and fine details.

● Material Range: Compatible with a variety of metal powders.

● Surface Finish: Parts often have a smooth finish, reducing the need for post-processing.

Directed Energy Deposition (DED)

DED printers utilize a focused energy source, such as a laser or electron beam, to fuse materials as they are deposited. DED can work with both powder and wire feedstock.

Key features of Directed Energy Deposition Metal 3D Printers:

● Repair and Additive Manufacturing: Ideal for repairing parts or adding material to existing components.

● Material Efficiency: Minimizes waste by depositing material only where needed.

Binder Jetting

Binder Jetting involves depositing a liquid binding agent onto layers of metal powder, which is then sintered to form solid parts.

Key Features of Binder Jetting 3D Printers:

● Speed: Faster than PBF due to no need for melting metal during the printing process.

● Cost-Effectiveness: Generally lower cost per part, especially for large runs.

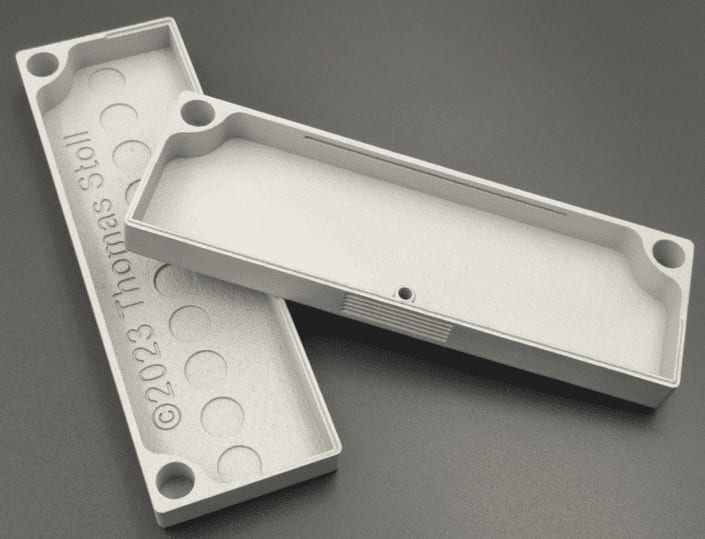

Material Extrusion

Material extrusion includes printers that extrude metal filament, similar to traditional FFF/FDM 3D printers, but with materials suitable for metal parts.

Key Features of Material Extrusion Metal 3D Printers:

● Accessibility: More affordable and user-friendly, making them suitable for smaller businesses and educational purposes.

● Versatility: Capable of printing with various metal-infused filaments.

Best Metal 3D Printers of 2025

1. Desktop Metal Studio System™ 2

The Desktop Metal Studio System™ 2 is a standout choice for in-house metal part production, offering a streamlined two-step workflow of printing and sintering that eliminates the need for solvent debinding. Designed for safety and accessibility in an office environment, it requires no special facilities or dedicated operators.

With its Bound Metal Deposition technology, the system produces high-quality parts suitable for a variety of industries, from manufacturing to consumer electronics. The Studio System™ 2 features a build volume of 300 x 200 x 200 mm, operates at sintering temperatures up to 1400°C, and is complemented by the user-friendly Fabricate software, which automates the transition from printing to sintering.

Image Source: Desktop Metal

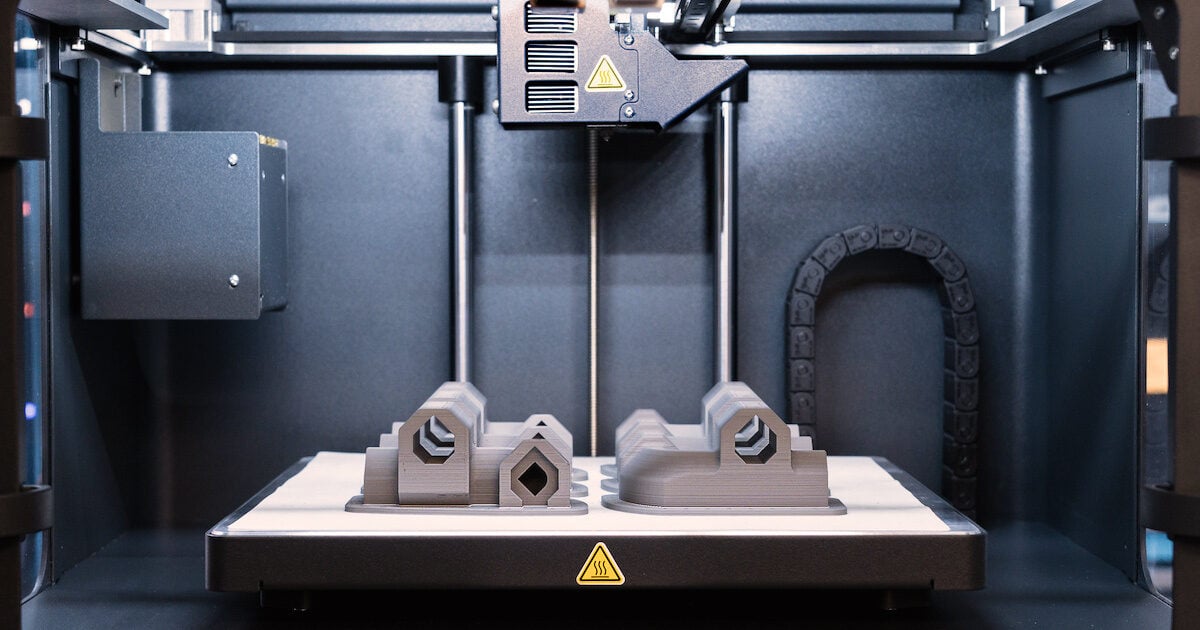

2. Raise3D Forge1 3D Printer

The Raise3D Forge1 is a versatile addition to the metal additive manufacturing market, offering a cost-effective solution for producing metal parts. Utilizing Fused Filament Fabrication (FFF) technology, the Forge1 is designed for reliability and ease of use. It boasts a generous build volume of 300 × 300 × 300 mm and features such as auto bed leveling and a glass build plate for enhanced printing performance.

Developed in collaboration with BASF, the Forge1 uses Ultrafuse® 316L and Ultrafuse® 17-4 metal filaments, ensuring high-strength green parts that are compatible with the Metal Injection Molding (MIM) industry’s catalytic debinding technology.

Image Source: Raise3D

3. Markforged Metal X™ System

The Markforged Metal X System is a comprehensive solution for metal 3D printing, designed to deliver industrial-grade parts with remarkable precision and reliability. It’s an accessible option for those looking to produce custom metal parts affordably. The system’s layer resolution ranges from 50 to 125 micrometers, allowing for clear, detailed parts. The Metal X System includes the Wash-1 and Sinter-1 and 2, streamlining the post-processing and increasing the print speed.

Image Source: Markforged

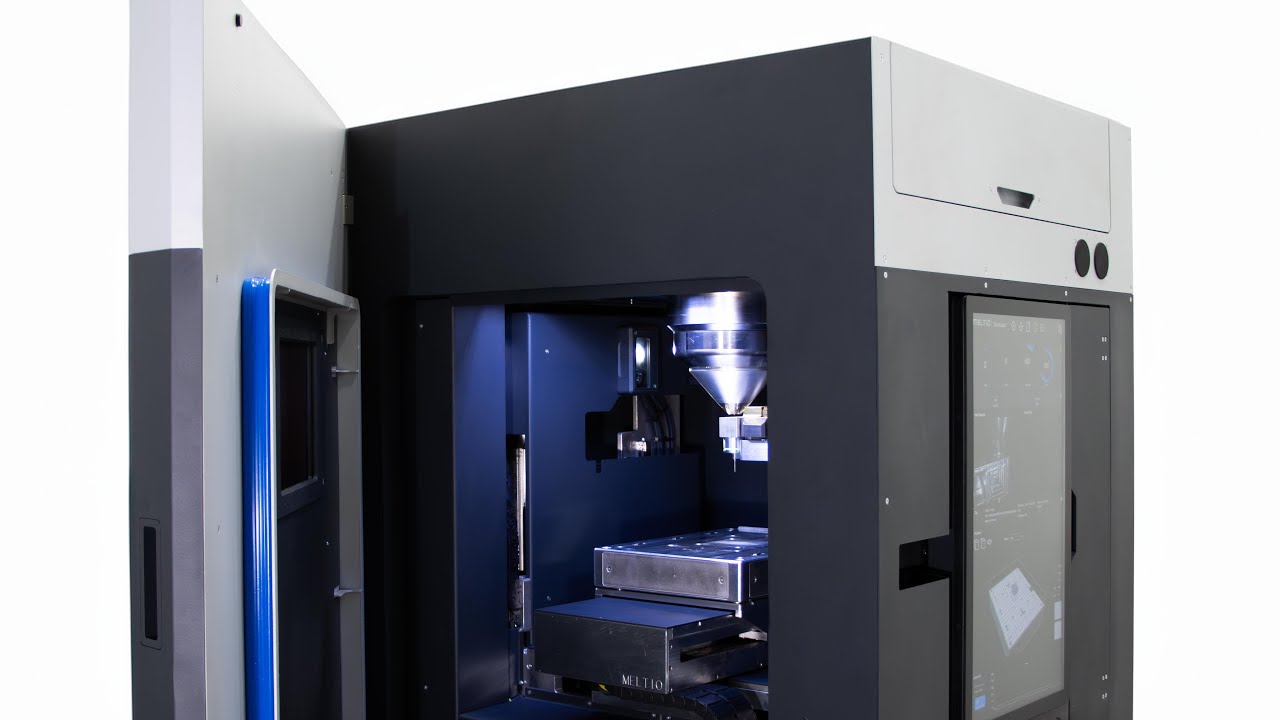

4. Meltio M600

The Meltio M600 is an industrial metal 3D printer that stands out for its ability to expand manufacturing capabilities with its blue laser technology, large build volume, and fully inert chamber, ensuring optimal material properties. It’s designed for ease of use with improved process control, advanced sensors, and live monitoring, which allows for consistent part production around the clock.

The M600 boasts a built-in 3-axis probing system and work-holding solutions, making it a robust addition to manufacturing operations. Its autonomous nature requires minimal operator interaction, and common tasks like manual laser alignment have been eliminated, increasing reliability and efficiency.

Image Source: Meltio

5. SLM®125

The SLM®125 is an industrial-grade metal 3D printer designed for the production of small to medium-sized parts with high precision and surface quality. It utilizes Selective Laser Melting (SLM) technology to fuse metallic powders layer by layer with a powerful laser beam.

The SLM®125 offers a build envelope of 125 mm x 125 mm x 125 mm. It’s praised for its ability to produce complex parts and functional prototypes with a closed-loop powder handling unit that ensures material efficiency and safety. Despite its smaller build volume compared to some competitors, the SLM®125 is recognized for its high-quality output and good print speed, making it a valuable asset for precision manufacturing.

Image Source: SLM Solutions

6. 3D Systems DMP Flex 100

The 3D Systems DMP Flex 100 is a precision metal 3D printer known for its exceptional surface finish and resolution, ideal for manufacturing small, complex parts. It boasts a build volume of 100 x 100 x 90 mm and utilizes a 100W laser to sinter fine metal powders, achieving surface quality of up to 5 Ra μm.

The printer’s proprietary powder deposition system allows for building angles down to 20° without supports, which, along with its patented layer compacting technology, enables the creation of intricate details and the thinnest wall thicknesses. The DMP Flex 100 is versatile, processing a broad spectrum of materials, including various grades of titanium and stainless steel, and comes with 3DXpert software to streamline the printing process.

Image Source: 3D Systems

7. HP Metal Jet S100 Solution

The HP Metal Jet S100 Solution is a professional metal 3D printing system designed for mass production of high-quality metal parts. It’s engineered to provide industrial-grade output with operational efficiency and maximum uptime, suitable for 24/7 manufacturing conditions.

The Metal Jet S100 is particularly noted for its integrated end-to-end digital system, which includes the HP Digital Production Suite for supply chain solutions and analytics. With a focus on the total cost of ownership, it aims to reduce the variable cost per part, enabling scalable production.

Image Source: HP

8. Velo3D Sapphire & Sapphire 1MZ

The Velo3D Sapphire & Sapphire 1MZ are advanced metal 3D printers designed for production-scale manufacturing, offering large build volumes and increased throughput. The Sapphire series is known for its ability to print complex geometries without the need for supports, thanks to its unique low-angle printing capabilities. Both models utilize eight 1kW lasers, ensuring faster printing at scale, and feature a proprietary non-contact recoater for improved build quality and reduced risk of part collisions.

The Sapphire printers are equipped with nearly 1,000 sensors for real-time quality monitoring and come with integrated software solutions for print preparation and quality assurance. The Sapphire 1MZ, in particular, boasts a build volume of 600 mm Ø by 1000 mm z-height, making it suitable for large, high-performance parts in industries such as aerospace, energy, and defense.

Image Source: Velo3D

9. EOS M 290

The EOS M 290 is a robust and reliable industrial 3D printer renowned for its Direct Metal Laser Sintering (DMLS) technology. The M 290 boasts a 400-watt fiber laser that fuses fine metal powder, layer by layer, to create objects with intricate geometries and precise dimensions. It offers a build volume of 250 x 250 x 325 mm, and its high beam quality and detail resolution make it ideal for manufacturing complex DMLS components with consistent properties across different jobs and machines.

The system is complemented by an intuitive management system, EOSPRINT, which optimizes CAD data for efficient job and workflow management. With a broad portfolio of materials and a comprehensive monitoring suite, the EOS M 290 sets the industry standard for producing qualified metal parts.

Image Source: EOS

3D Printed Metal Parts Applications

Aerospace and Defense

Components for aerospace and defense, such as turbine blades, fuel nozzles, and engine components, are being produced with complex internal structures that enhance performance while reducing weight.

Medical Devices

The medical field benefits from the customization capabilities of metal 3D printing. Implants, surgical tools, and prosthetics can be tailored to individual patient anatomy, improving outcomes and patient comfort.

Automotive Industry

The automotive sector utilizes metal 3D printing for prototyping and end-use parts. From intricate gearbox components to lightweight structural elements, metal 3D printing is driving innovation and efficiency in automotive design and manufacturing.

Energy Sector

In energy, particularly in oil and gas, metal 3D printing is used to produce parts that can withstand extreme conditions, including components like drill bits and heat exchangers.

Tooling and Robotics

Metal 3D printing is revolutionizing tooling by allowing for the creation of custom, complex tools that improve manufacturing processes. In robotics, it enables the production of unique end-of-arm tooling that can adapt to various tasks.

Consumer Products

The consumer goods industry is embracing metal 3D printing for its ability to create bespoke jewelry, watches, and luxury items, as well as functional components for electronics that require thermal and electrical conductivity.

Education and Research

Educational institutions and research organizations use metal 3D printing for prototyping and experimenting with new designs and materials.

3DSPRO Custom Metal 3D Printing Services

3DSPRO delivers professional custom metal 3D printing services, providing a seamless process from digital design to functional parts with our comprehensive SLM 3D Printing Solutions. We have an experienced technical and general support team that can respond to your project quickly and efficiently. In addition to metal 3D printing services, we offer advanced metal post-processing with 3D Plus™ that ensures the highest quality for finished parts.

COMMENTS

- Be the first to share your thoughts!