Watching your 3D print slowly fall, warp, or peel off the bed mid-print is frustrating. Print failures waste time, filament, and patience. But don’t hit "cancel" just yet! In this guide, we break down what to do when 3d print is slowly falling. We’ll help you stop the slump and get back to flawless printing.

Immediate Steps to Save Your Print

1. Pause the Printer

• Inspect layers for warping, shifting, or poor adhesion.

• Look for filament blobs or nozzle drags that could knock the print loose.

2. Check Bed Adhesion

• Gently test if the print is lifting at the edges or corners.

• If partially detached, use a glue stick or tape to re-stick it temporarily.

3. Document the Problem

• Snap photos of the failure point and note settings (temperature, speed, layer height).

Troubleshooting Checklists

|

Checklists |

Why it happens? |

How to fix it? |

|

Poor Bed Adhesion |

Dirty beds, uneven leveling, or incorrect temperatures cause prints to detach. |

1. Use the “paper test” to ensure the nozzle is evenly spaced (0.1mm gap). 2. Print a bed leveling test to fine-tune. 3. Wipe with isopropyl alcohol (IPA) to remove oils and dust. 4. For glass beds, use soap and water for a deep clean. 5. Apply glue stick, hairspray, or painter’s tape (blue tape for PLA, PEI sheets for PETG). 6. Increase bed temperature: 60–70°C for PLA, 90–110°C for ABS. 7. Add a brim or raft in your slicer to widen the base. A 5–8mm brim can save tall, narrow prints. |

|

Incorrect Print Speed or Temperature |

Fast initial layers or cold nozzles weaken bonding. |

1. Set the first layer speed to 20–30 mm/s for better stickiness. 2. Increase by 5–10°C if layers aren’t bonding (e.g., PLA: 200–220°C). 3. Decrease if overheating causes drooping (use a cooling fan for PLA). |

|

Inadequate Cooling |

Poor cooling can cause the upper layer to sag and make the print unstable. |

1. Keep the fan off for the first 3–5 layers to improve adhesion. 2. PLA: 100% fan speed after layer 5. 3. ABS: 0–20% fan speed (or none) to prevent warping. |

|

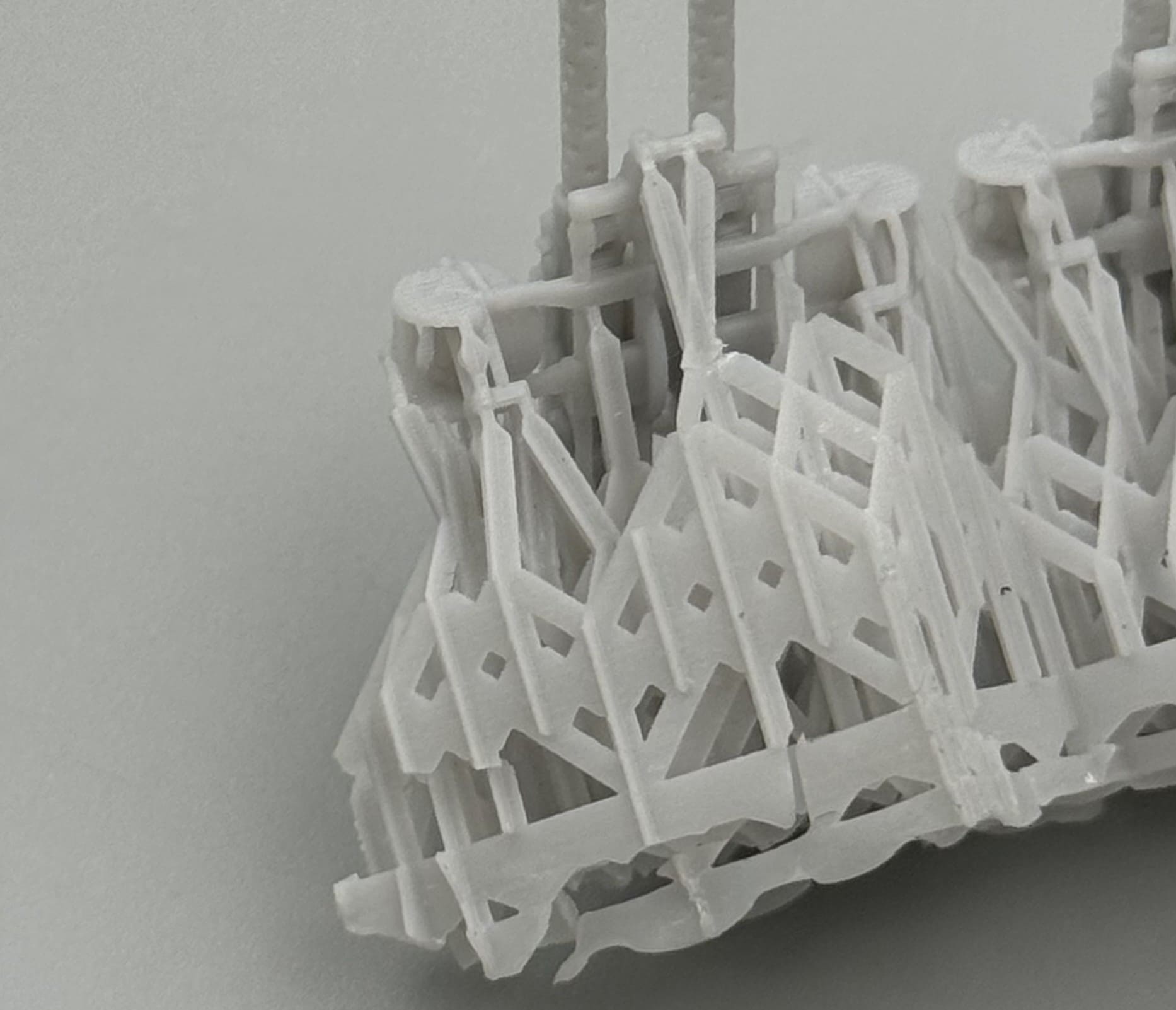

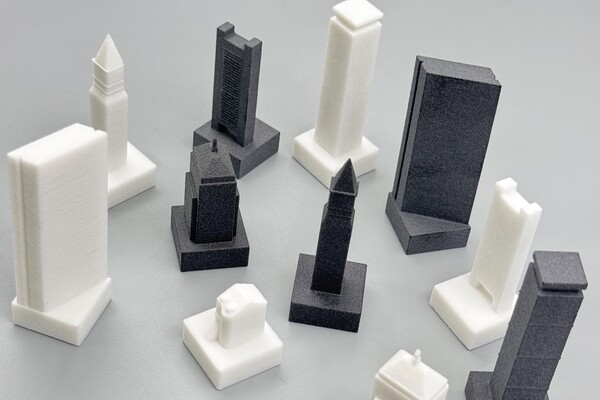

Weak Support Structures |

Overhangs or bridges collapse without proper supports. |

1. Use “touching build plate” supports in Cura or PrusaSlicer. 2. Try tree supports to reduce filament waste and improve stability for complex shapes. |

|

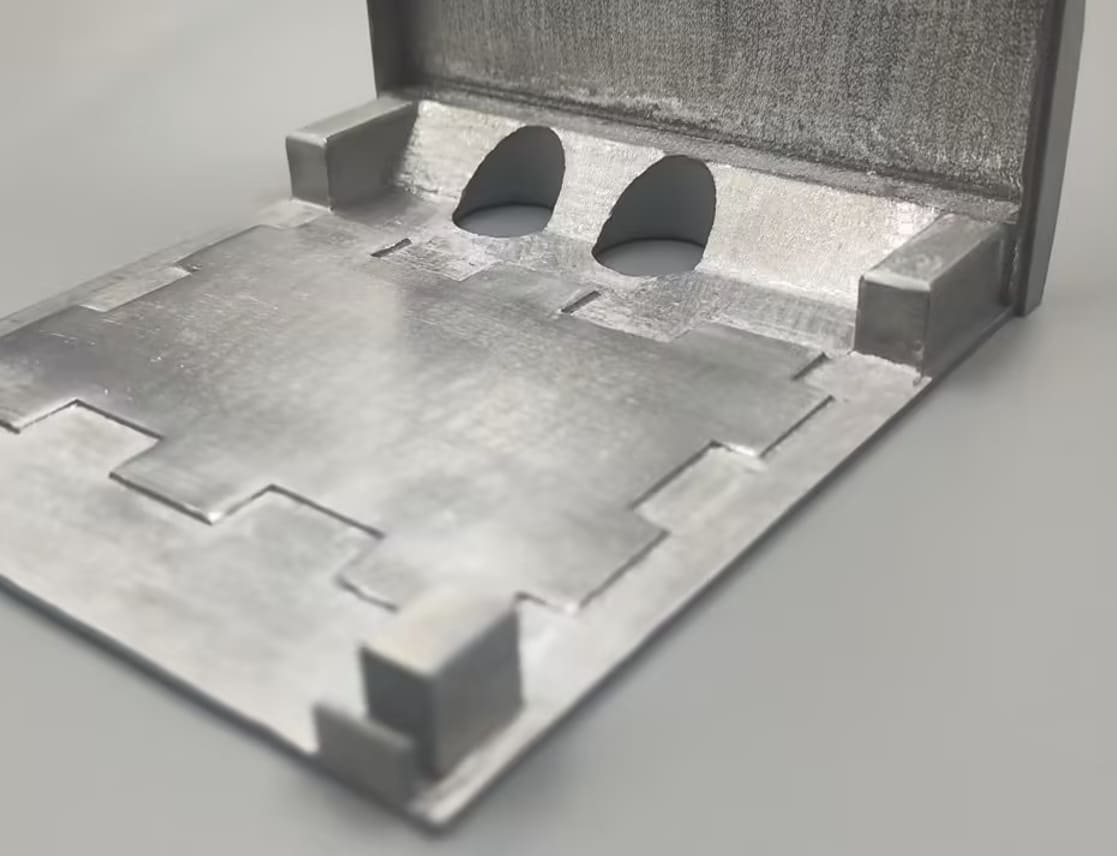

Design Flaws |

Top-heavy models or sharp corners create stress points. |

1. Modify the model in Tinkercad or Fusion 360 to add a larger base. 2. Add chamfers or fillets as rounded edges reduce lifting forces and improve layer bonding. |

Prevention Checklist

1. Level the bed before every print.

2. Clean the build plate with IPA.

3. Use a brim/raft for tall models.

4. Store filament in a dry box. (Make sure the material is in good condition.)

5. Run calibration tests monthly (e.g., XYZ cube, temp towers).

A slowly falling 3D print isn’t doomed! Start with bed adhesion fixes, then tweak temperature, cooling, and supports. Regular maintenance and smart design choices prevent most failures. Remember, even pros face print disasters—each one is a chance to learn.

COMMENTS

- Be the first to share your thoughts!

![STL File Guide [Updating]](/Uploads/202412/677216e3ed6e2.jpg)