What is Carbon-Fiber Reinforced PA6?

Carbon‑fiber reinforced PA 6 is a composite material made by dispersing short chopped carbon fibers into a polyamide 6 matrix, commonly known as Nylon 6. The carbon fibers act as a reinforcing phase that raises stiffness, improves dimensional stability, and increases heat deflection temperature compared with unfilled PA 6. In 3D printing, the composite is available in two primary forms: high‑temperature filament for fused deposition modeling (FDM/FFF) and sinterable powder for selective laser sintering (SLS).

The carbon fibers used are typically short and randomly oriented rather than continuous, which simplifies processing and reduces cost while still delivering substantial gains in modulus and thermal performance. Because the fibers are discontinuous, mechanical properties are influenced by fiber length, aspect ratio, orientation, and the quality of the fiber‑matrix interface. The result is a material that retains many of nylon’s useful traits, such as chemical resistance in dry conditions, toughness, and machinability, while trading some ductility for stiffness and thermal stability.

Image Copyright © 3DSPRO Limited. All rights reserved.

Key Properties

Mechanical Performance

PA 6 CF shows a marked increase in tensile modulus and flexural stiffness relative to neat PA 6, which makes it attractive for structural parts, fixtures, and tooling where rigidity is more important than elongation. Tensile strength often increases modestly, but elongation at break typically decreases, so parts become less ductile and more prone to brittle failure under concentrated loads.

Thermal Behavior

Carbon fibers raise the composite’s heat deflection temperature and reduce thermal expansion. That improves dimensional stability under elevated temperatures and reduces creep compared with unfilled nylon. For applications that see sustained heat, PA 6 CF can maintain stiffness where neat nylon would soften.

Moisture Sensitivity

Nylon 6 remains hygroscopic. It absorbs water from the environment, which plasticizes the polymer and reduces stiffness and glass transition temperature. Carbon fiber does not eliminate this behavior. Proper drying before printing and controlled storage are essential to preserve mechanical properties and avoid printing defects such as poor interlayer adhesion or hydrolysis during high‑temperature processing.

Wear and Abrasion

Carbon fibers improve dry wear resistance in many sliding or bearing applications, but the fibers are abrasive to tooling. Hardened nozzles, carbide cutters, and wear‑resistant end mills are recommended for FDM extrusion and post‑processing.

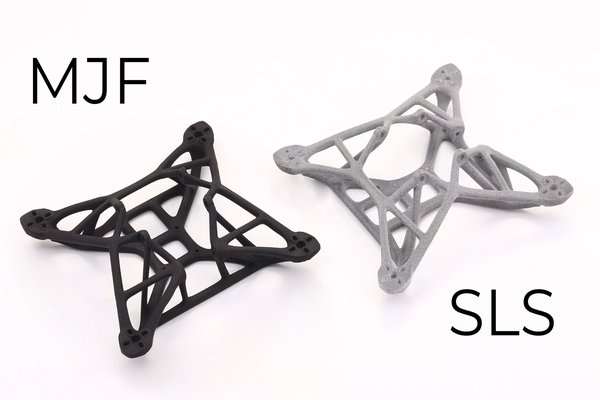

Printability and Anisotropy

In FDM, parts are anisotropic. Strength and stiffness vary with print orientation because fibers tend to align with the extrusion direction. In SLS, the powder bed and sintering process produce more isotropic behavior, though fiber orientation and distribution still influence local properties.

Pros and Cons

|

Pros |

Cons |

|

High stiffness and improved dimensional stability make PA 6 CF suitable for load‑bearing parts and tooling. |

Reduced ductility and increased brittleness compared with unfilled nylon; the design must avoid sharp stress concentrators. |

|

Better thermal performance than neat nylon allows use in hotter environments. |

The hygroscopic nature remains; drying and controlled storage are mandatory. |

|

Improved dry wear resistance for sliding or bearing surfaces. |

Abrasive to equipment, expect higher nozzle and tool wear and plan maintenance accordingly. |

|

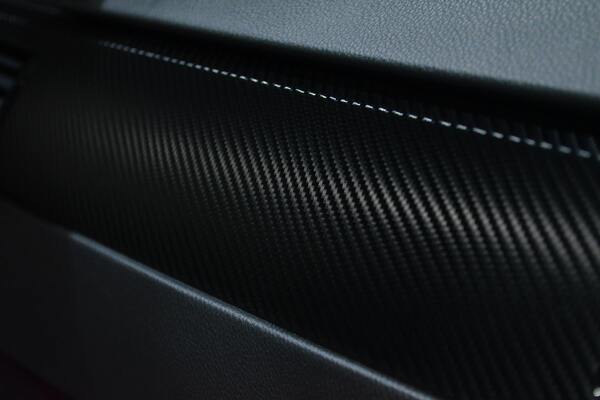

Industrial appearance and surface texture can be desirable for functional prototypes and end‑use parts. |

Higher material and processing costs than standard nylon or PLA, and some printers require high‑temperature hotends or SLS systems. |

SLS 3D Printed PA 6 CF

Why SLS Is Often Preferred For PA 6 CF

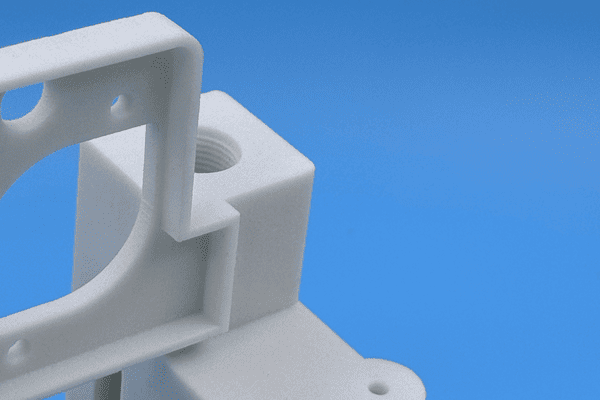

Selective Laser Sintering produces parts by fusing powder in a heated bed, which supports geometry during build and reduces warping. For PA 6 CF, SLS powders are engineered to achieve good flow, consistent packing, and reliable sintering despite the presence of carbon fibers. The powder bed environment and layerwise sintering yield parts that are closer to isotropic in mechanical response than FDM prints, and SLS parts typically have better dimensional accuracy and finer feature fidelity.

Processing Considerations

Laser parameters must be tuned to account for the thermal conductivity and absorptivity changes introduced by carbon fibers. Powder recycling strategies need careful controlfiber, content and particle size distribution can change with reuse, affecting mechanical properties and surface finish. Porosity and fiber pull‑out are potential failure modes; optimizing energy density and powder handling reduces these defects. Post‑build conditioning, such as heat treatment or infiltration, can further improve density and mechanical performance.

Typical Outcomes

SLS PA 6 CF parts are commonly used where dimensional stability, isotropy, and surface finish matter, for example, functional prototypes, end‑use housings, and tooling components that require consistent mechanical behavior in multiple axes.

Post-Processing Options

Drying and Conditioning

Always dry filament or powder before printing, and consider post‑build drying to remove absorbed moisture. Moisture can cause hydrolysis during high‑temperature processing and degrade mechanical properties.

Smoothing

Bead blasting, tumbling, or sanding can smooth surfaces and remove powder residue. Because nylon is not readily solvent‑smoothed, mechanical finishing or thin conformal coatings (epoxy, polyurethane) are common to improve appearance and seal the surface against moisture.

Sealing and Infiltration

Epoxy or resin infiltration can increase surface hardness, reduce porosity, and lower moisture uptake. It is especially useful for SLS parts intended for structural use or for parts exposed to humid environments.

Machining and Secondary Operations

PA 6 CF machines well but accelerates tool wear. Use carbide or coated tools, slower feed rates, and frequent tool inspection. Tapping and threaded inserts are common for assembly; heat‑set inserts can provide durable threads in nylon composites.

Protective Coatings

For wear or chemical exposure, consider conformal coatings or specialized paints that adhere to nylon. Coatings can also improve UV resistance and reduce surface friction.

Applications

Industrial Tooling and Fixtures

Jigs, fixtures, and assembly aids benefit from PA 6 CF’s stiffness and dimensional stability. The material’s thermal resistance helps when fixtures are exposed to elevated temperatures during manufacturing.

Structural Components and Brackets

Lightweight structural parts, mounting brackets, and housings that require rigidity and thermal stability are common uses. Designers should avoid thin cantilevers and instead use ribs and fillets.

Automotive and Transportation

Under‑hood components in dry zones, sensor housings, and interior structural parts can leverage PA 6 CF’s thermal and dimensional advantages. Corrosion resistance and weight savings are additional benefits.

Tooling Inserts and Low‑Volume Production

SLS PA 6 CF can produce tooling inserts and short‑run production parts that need stiffness and heat resistance without the lead time of metal tooling.

Prototyping for Functional Validation

When prototypes must reflect final stiffness and thermal behavior, PA 6 CF provides a closer match to metal or high‑performance thermoplastics than unfilled nylons.

COMMENTS

- Be the first to share your thoughts!