Choosing the right material for your 3D printing project depends heavily on the manufacturing process and your application’s requirements. Below, we break down materials by technology, highlighting their strengths, limitations, and ideal uses. Check out these 3D printing materials cheat sheets!

FDM (Fused Deposition Modeling)

√ Process Pros: Low cost, wide material variety, user-friendly.

× Process Cons: Visible layer lines, limited precision.

|

Material |

Key Properties |

Best Uses |

|

PLA |

Biodegradable, easy to print |

Prototypes, decorative items |

|

PETG |

Durable, water-resistant |

Functional parts, outdoor tools |

|

ABS |

Heat-resistant, tough |

Automotive parts, enclosures |

|

TPU |

Flexible, shock-absorbing |

Phone cases, seals, grips |

|

Nylon |

Strong, abrasion-resistant |

Gears, hinges, mechanical parts |

SLA/DLP (VAT Photopolymerization)

√ Process Pros: Ultra-high precision, smooth surfaces.

× Process Cons: Brittle if uncured, limited longevity.

|

Material |

Key Properties |

Best Uses |

|

Standard Resin |

High detail, smooth finish |

Jewelry, dental models |

|

Tough Resin |

Mimics ABS strength |

Functional prototypes |

|

Flexible Resin |

Rubber-like elasticity |

Soft grips, wearable prototypes |

|

Biocompatible Resin |

Safe for medical use |

Surgical guides, implants |

|

Ceramic-Filled Resin |

Heat-resistant |

Molds, engineering tools |

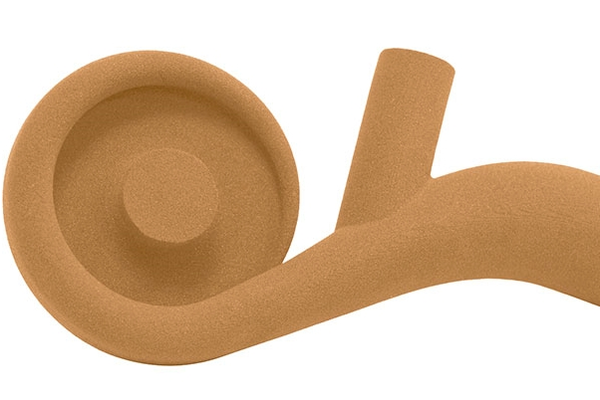

SLS (Selective Laser Sintering)

√ Process Pros: No supports needed, strong functional parts.

× Process Cons: Rough surface finish, expensive machines.

|

Material |

Key Properties |

Best Uses |

|

PA 12 (Nylon 12) |

Durable, chemical-resistant |

Hinges, prosthetics, ducts |

|

PA 11 |

Flexible, bio-based (castor oil) |

Snap-fit parts, eco-designs |

|

TPU Powder |

Elastic, wear-resistant |

Shoe midsoles, seals |

|

Glass-Filled |

Stiff, heat-resistant |

Automotive components |

MJF (Multi Jet Fusion)

√ Process Pros: Faster than SLS, consistent quality.

× Process Cons: Limited material options.

|

Material |

Key Properties |

Best Uses |

|

PA 12 |

Smooth finish, high reusability |

Industrial end-use parts |

|

PA 11 |

Bio-based, flexible |

Consumer product snap-fits |

|

PP |

Chemical-resistant, lightweight |

Fluidic systems, containers |

|

TPU Powder |

Elastic, wear-resistant |

Industrial gasket, seals |

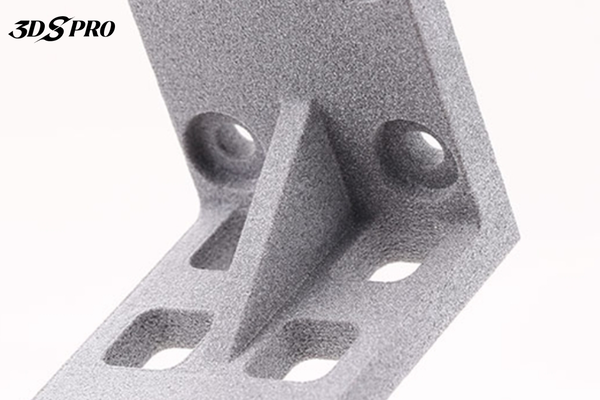

SLM/DMLS (Metal 3D Printing)

√ Process Pros: Complex metal parts, unmatched strength.

× Process Cons: Expensive, requires post-processing.

|

Material |

Key Properties |

Best Uses |

|

Stainless Steel |

Corrosion-resistant |

Industrial tools, marine parts |

|

Aluminum |

Lightweight, strong |

Aerospace components |

|

Titanium |

Biocompatible, high strength |

Medical implants, aerospace |

|

Inconel 718 |

Heat-resistant (up to 700°C) |

Jet engine parts |

|

Copper |

High thermal/electrical conductivity |

Heat exchangers, electronics |

Binder Jetting

√ Process Pros: Fast, scalable for large batches.

× Process Cons: Lower strength, requires infiltration.

|

Material |

Key Properties |

Best Uses |

|

Sand |

Heat-resistant, porous |

Foundry molds, casting cores |

|

Stainless Steel |

Low-cost metal parts |

Decorative items, prototypes |

|

Ceramics |

Heat-resistant, intricate designs |

Art, architectural models |

Material Jetting (PolyJet)

√ Process Pros: Multi-material/color prints, ultra-fine detail.

× Process Cons: Fragile, limited to small parts.

|

Material |

Key Properties |

Best Uses |

|

Digital ABS |

Combines rigidity and toughness |

Functional prototypes |

|

Rubber-Like Resin |

Shore A flexibility (e.g., 50A) |

Soft grips, gaskets |

|

Transparent Resin |

Optical clarity |

Lenses, light guides |

|

Multi-Material |

Mix rigid/flexible/color in one print |

Product design prototypes |

DED (Directed Energy Deposition)

√ Process Pros: Ideal for repairing large metal parts.

× Process Cons: Low resolution, requires expert operation.

|

Material |

Key Properties |

Best Uses |

|

Titanium |

High-strength repairs |

Aerospace part restoration |

|

Stainless Steel |

Durable, corrosion-resistant |

Industrial machinery repairs |

Quick Comparison Chart

|

Process |

Best For |

Strength |

Precision |

Cost |

|

FDM |

Prototyping, hobbyists |

Medium |

Low-Medium |

$ |

|

SLA/DLP |

Detailed models, dental |

Low-Medium |

High |

$$ |

|

SLS/MJF |

Functional nylon parts |

High |

Medium |

$$$ |

|

SLM/DMLS |

Aerospace/medical metal |

Very High |

High |

$$$$ |

|

Binder Jetting |

Casting molds, ceramics |

Low-Medium |

Medium |

$$ |

|

Material Jetting |

Multi-material prototypes |

Medium |

Ultra-High |

$$$$ |

COMMENTS

- Be the first to share your thoughts!