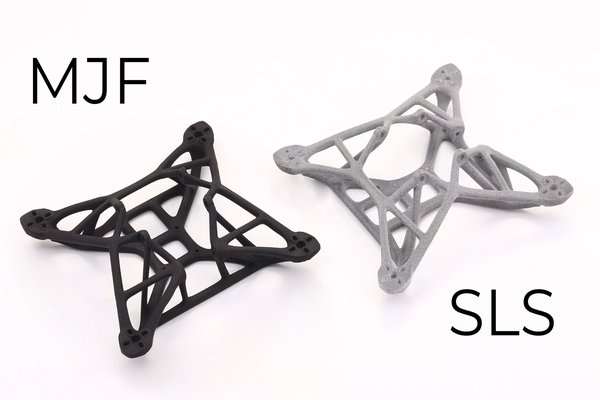

Selective Laser Sintering (SLS) Essentials

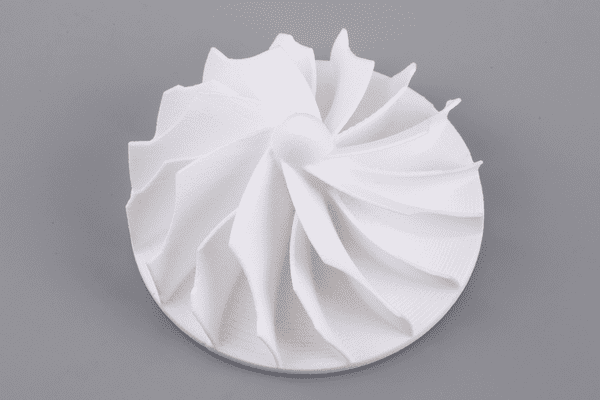

Selective Laser Sintering (SLS) operates by spreading a fine layer of polymer powder across a build platform and then selectively fusing regions of that powder with a high-powered laser. The laser energy raises the temperature of the particles just below their melting point, causing them to bond together into a solid structure. Once a layer is complete, the platform lowers slightly, a new layer of powder is applied, and the process repeats until the part is fully built.

• No support structures required: The surrounding unsintered powder acts as a natural support, enabling complex geometries.

• Layer-by-layer precision: Each pass of the laser ensures dimensional accuracy and repeatability, critical for robotics components.

Material Options Commonly Used

SLS is compatible with a range of engineering-grade polymers, each offering distinct mechanical properties:

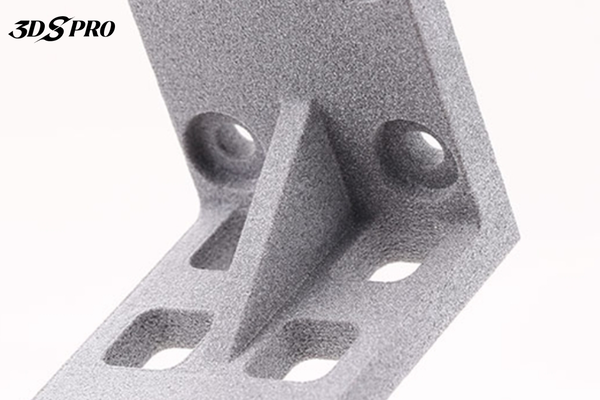

• PA 12 (Polyamide 12): Excellent balance of strength, toughness, and dimensional stability. Widely used for housings, brackets, and load-bearing parts.

• PA 11 (Polyamide 11): More flexible than PA12, with superior impact resistance and chemical durability. Ideal for dynamic robotic components.

• Composites (glass-filled or carbon-filled polyamides): Enhanced stiffness and reduced creep, making them suitable for structural frames and arms.

• Specialty polymers (PP, TPU): Polypropylene provides chemical resistance and lightweight flexibility, while TPU offers elasticity for shock-absorbing elements.

Key Engineering Properties

Robotics demands materials that can withstand mechanical stresses while minimizing weight. SLS polymers deliver:

• Tensile strength: Ensures components can resist pulling forces and maintain integrity under load.

• Stiffness: Provides rigidity for precision movements, critical in robotic arms and end-effectors.

• Fatigue resistance: Allows parts to endure repetitive motion cycles without cracking or deformation, extending service life in dynamic robotic systems.

Image Copyright © 3DSPRO Limited. All rights reserved.

Engineering Challenges in Robotics

Robotics is a field defined by constant trade-offs. Engineers must balance weight, strength, flexibility, and manufacturability to achieve optimal performance. Some of the most pressing challenges include:

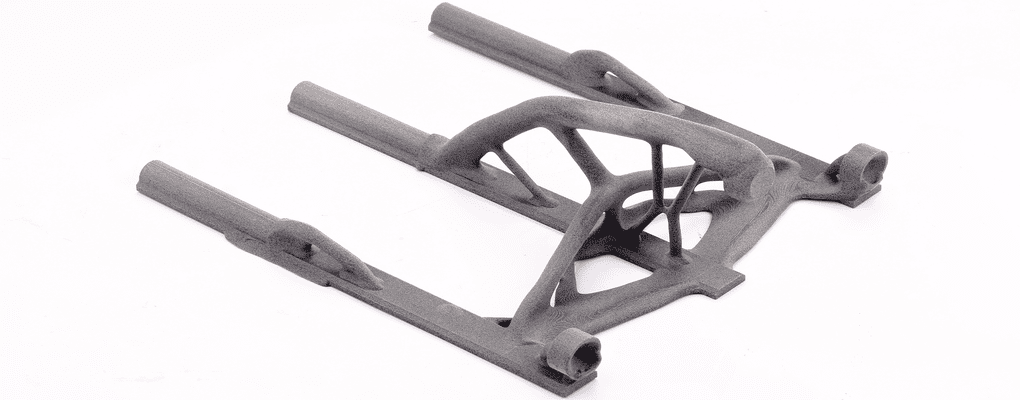

• Weight-to-strength ratio: Robotic arms, drones, and mobile platforms require components that are strong enough to withstand operational stresses but light enough to minimize energy consumption and maximize payload capacity.

• Dynamic loading: Robots often operate under repetitive motion cycles, which introduce fatigue stresses. Materials must resist cracking and deformation over thousands of cycles.

• Compact design constraints: Space is limited in robotic assemblies. Components must integrate multiple functions—structural support, housing, and sometimes even cable routing—within tight envelopes.

• Customization and iteration speed: Robotics development is iterative. Engineers need rapid prototyping and small-batch production to refine designs without incurring high tooling costs.

Advantages of SLS for Lightweight Structures

SLS offers several engineering benefits that directly address the challenges of robotics:

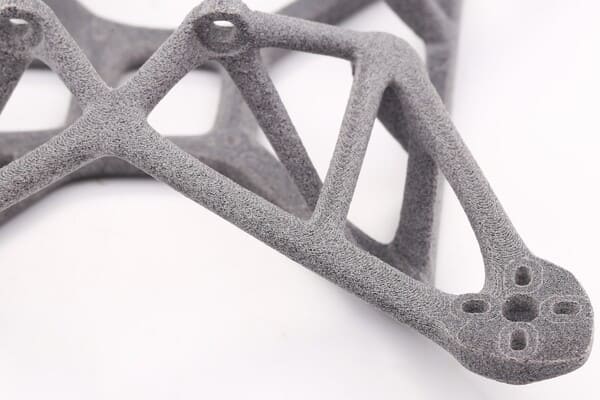

• Design freedom: Engineers can create intricate geometries, including lattice structures, hollow beams, and integrated joints. These designs reduce weight while maintaining stiffness.

• Material efficiency: Unused powder can often be recycled, making the process more sustainable compared to subtractive methods.

• Performance gains: Lightweight components improve robot agility, reduce energy consumption, and increase payload capacity.

• Rapid iteration: Prototypes can be produced quickly without tooling, enabling engineers to test multiple design variations in days rather than weeks.

• Durability: SLS parts exhibit excellent mechanical properties, including high tensile strength and resistance to wear, making them suitable for demanding robotic environments.

Structural Optimization Strategies

Finite Element Analysis (FEA)

Engineers employ Finite Element Analysis to simulate stresses, strains, and fatigue cycles, ensuring that SLS designs meet performance requirements before production. The predictive modeling validates structural integrity under real-world conditions, reducing costly iterations and failures.

Lattice Infills

Rather than relying on solid parts, lattice infills deliver strength with minimal material usage. These internal structures can be precisely tuned to achieve desired stiffness, flexibility, or shock absorption, making them ideal for robotics components that demand lightweight efficiency without compromising durability.

Topology Optimization

Through topology optimization, material is strategically removed from non-critical regions, leaving only the essential load-bearing framework. Topology optimization minimizes weight while maintaining mechanical performance, enabling robotics engineers to push the limits of design efficiency.

Hybrid Structures

By combining rigid SLS components with flexible TPU elements, engineers create hybrid structures that balance strength and adaptability, allowing robots to maintain precision in load-bearing areas while incorporating flexibility where shock absorption or movement compliance is required.

Industrial Applications

• Manufacturing robotics: End-of-arm tooling, jigs, and fixtures benefit from lightweight SLS components that reduce inertia and improve cycle times.

• Service robots: Lightweight casings and housings improve mobility and reduce power consumption in cleaning robots, delivery bots, and healthcare assistants.

• Aerospace robotics: UAVs and autonomous systems require lightweight yet durable components. SLS enables the production of aerodynamic housings and structural arms with optimized geometries.

• Defense robotics: Autonomous ground vehicles and drones benefit from rugged, lightweight parts that withstand harsh environments.

• Medical robotics: Surgical robots require precision components with complex geometries. SLS allows for sterile, lightweight housings and ergonomic designs.

3DSPRO SLS 3D Printing Service

For organizations seeking to leverage SLS without investing in expensive equipment, professional services like 3DSPRO provide a practical solution. Our SLS 3D printing service specializes in high-performance polymers tailored for robotics applications:

• Nylon (PA 12, PA 11, PA 6): Known for its excellent tensile strength, wear resistance, and dimensional stability. Ideal for structural components such as housings, brackets, and load-bearing arms.

• Polypropylene (PP) Glass-Filled: Offers chemical resistance and flexibility. Suitable for components exposed to harsh environments or requiring impact resistance.

• Thermoplastic Polyurethane (TPU): Provides elasticity and shock absorption. Perfect for flexible joints, vibration-dampening elements, and protective casings.

Why choose 3DSPRO?

• Engineering-grade quality: Our SLS parts meet stringent mechanical standards, ensuring reliability in robotics applications.

• Customization: Clients can submit CAD files and receive tailored components optimized for their specific robotic systems.

• Rapid turnaround: Prototypes and production parts are delivered quickly, supporting iterative design cycles.

• Scalability: From single prototypes to small-batch production, we adapt to project needs without requiring costly tooling.

By combining advanced SLS technology with material expertise, we empower robotics engineers to push the boundaries of design. Whether developing lightweight drone arms, flexible robotic grippers, or durable exoskeleton frames, our SLS 3D printing service provides the precision and reliability required for next-generation robotics.

Image Copyright © 3DSPRO Limited. All rights reserved.

COMMENTS

- Be the first to share your thoughts!