What is screen printing?

Screen printing, also known as silk screening, is a versatile printing technique that uses a mesh screen, ink, and a stencil to transfer designs onto various substrates. The screen acts as a stencil, allowing ink to pass through specific areas onto the material below. Screen printing is known for its adaptability, working on textiles, paper, plastics, metals, etc.

Benefits of Screen Printing

• Durability: Screen-printed designs are resistant to fading, cracking, and peeling, even after repeated washing or exposure to harsh environments.

• Vibrant Colors: Screen printing uses thick ink layers that produce bold, opaque colors that stand out on dark or textured surfaces.

• Versatility: Screen printing is suitable for flat, curved, or irregular surfaces, making it ideal for everything from T-shirts to industrial components.

• Cost-Effectiveness: It is economical for large batches due to low per-unit costs after the initial setup.

• Customization: Screen printing enables intricate designs, gradients, and multi-color prints with precise alignment.

How does screen printing work?

1. Design Preparation

The artwork is created digitally and separated into color layers. Each color requires a separate screen, so complex designs demand precise alignment planning.

2. Screen Preparation

A fine mesh screen (often polyester or nylon) is coated with a light-sensitive emulsion. Once dry, the stencil film (with the design) is placed on the screen and exposed to UV light. The light hardens the emulsion except where the design blocks it, creating a stencil after rinsing.

3. Setup and Alignment

The screen is mounted on a press, and the substrate (e.g., fabric, plastic, or metal) is positioned beneath it. Registration marks ensure perfect alignment for multi-color prints.

4. Ink Application

Ink is poured onto the screen. A squeegee is pulled across the mesh, forcing ink through the open stencil areas onto the substrate. This step is repeated for each color layer.

5. Curing

The printed item is dried using heat presses or UV lamps to solidify the ink, ensuring adhesion and durability.

6. Finishing

Excess ink or debris is removed, and quality checks are performed for consistency.

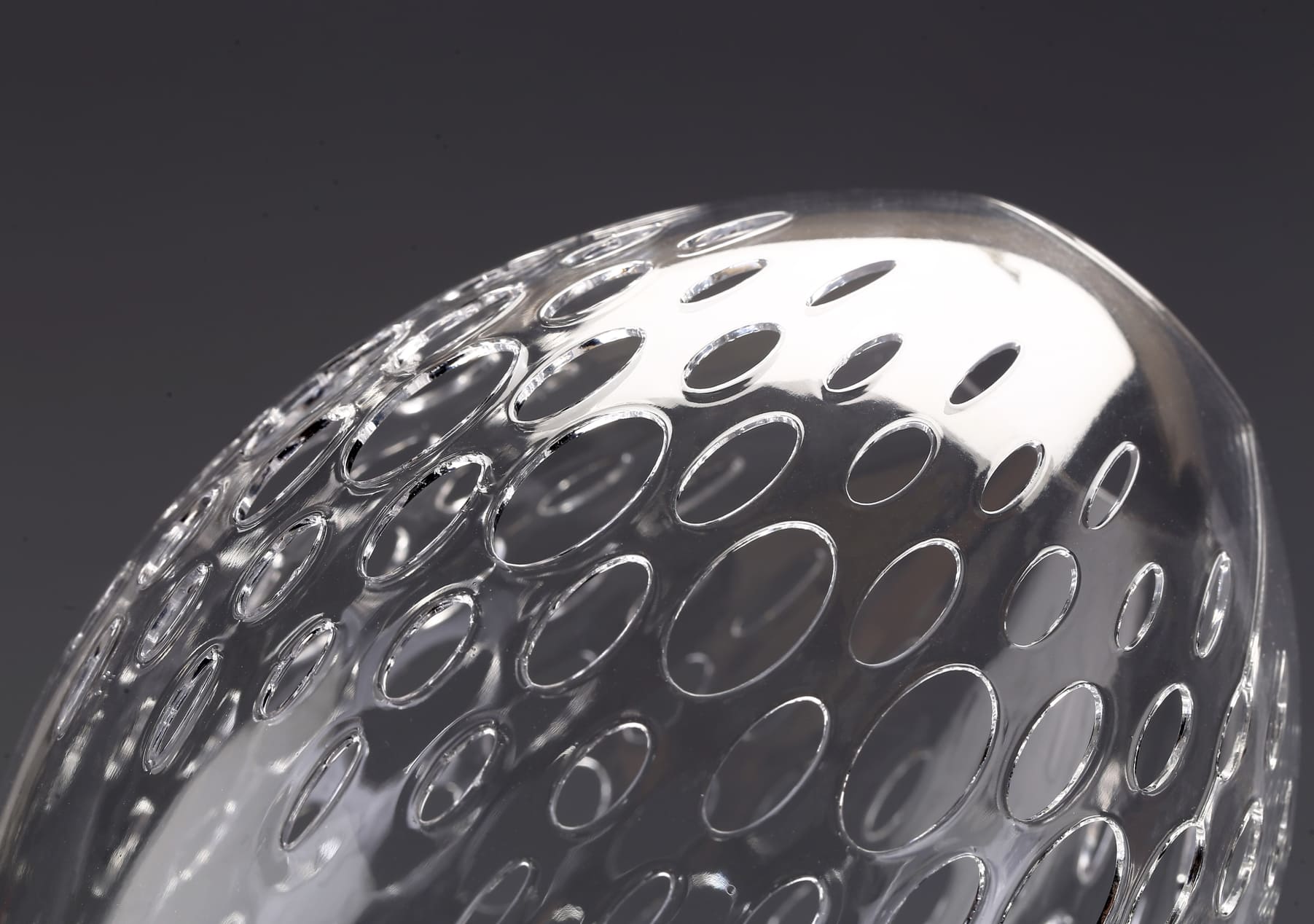

Can screen printing be applied on 3D printed parts?

Yes, screen printing can enhance 3D printed parts, but challenges arise due to their unique textures and shapes:

Challenges

1. Surface Texture: Layer lines from 3D printing can cause uneven ink application.

2. Material Compatibility: Plastics like PLA or ABS may require specialized inks for adhesion.

3. Complex Geometries: Curved or irregular surfaces complicate screen alignment.

Solutions

1. Surface Smoothing: Sanding, chemical treatments (e.g., acetone vapor for ABS), or epoxy coatings create a uniform printing surface.

2. Specialized Inks: Flexible or solvent-based inks adhere better to plastics.

3. Custom Fixtures: Jigs and adjustable screens ensure precise alignment on curved parts.

Applications

Adds logos, instructions, or decorative elements to 3D prototypes, medical devices, or consumer products. It can also apply conductive inks for functional electronics integration.

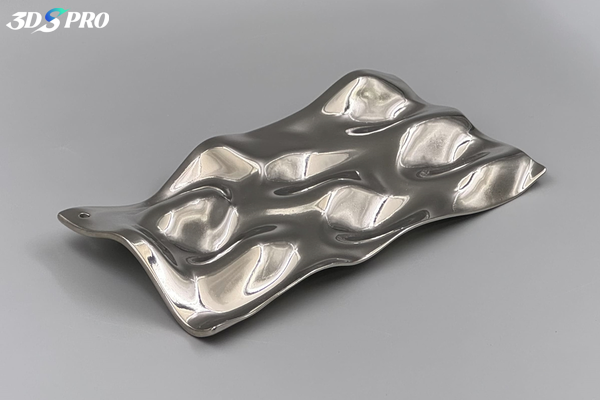

We Offer Screen Printing Service for 3D Printed Parts

At 3DSPRO, our 3D Plus™ Solutions offer professional screen printing to 3D printed parts and deliver unmatched quality.

Our Services Include:

• Surface Preparation: Post-processing to smooth 3D parts for flawless printing.

• Custom Ink Formulations: Inks tailored for resin, nylon, and flexible material.

• Multi-Color and Gradient Printing: Advanced registration techniques for complex designs.

• Durable Curing: Heat or UV methods to ensure long-lasting results.

Why Choose 3DSPRO?

• Dedicated Services: "comments from our customer: The 3DSPRO team is professional, knowledgeable and experienced. They respond quickly and efficiently whether it be technical questions or just general support. We do feel they value our business and genuinely care about manufacturing the best parts they can for us. We would highly recommend working with them and will continue to leverage their team for our projects."

• Expert Team: Experienced in hybrid manufacturing solutions. (read hybrid manufacturing case study)

• Rapid Turnaround: From prototyping to mass production with quick lead times. (read case study)

Whether you need branded prototypes, functional components, or artistic creations, we are here to help!

COMMENTS

- Be the first to share your thoughts!