What kind of 3D prints you want to make?

Choosing the right 3D printer starts with a fundamental question: What do you want to create?

You'll need to think of the purpose and functionality of your creations first.

When it comes to prototyping, a 3D printer that can produce models with fine details and dimensional accuracy is crucial for engineers, designers, and inventors who need to test form, fit, and function. Look for printers with high resolution and low-layer height capabilities. Additionally, consider the printer's ability to handle various materials, as prototypes often require different properties such as rigidity or heat resistance.

Suppose your goal is to print parts that will be put to practical use, especially those that need to withstand mechanical stress, temperature variations, or chemical exposure. In that case, you'll need a robust printer. Materials like ABS, Nylon, Polycarbonate, and PETG are known for their strength and durability. Printers designed for these materials often have heated beds and enclosed build chambers to ensure consistent quality.

3D printed art and decor are vibrant and diverse. Printers that offer a wide range of colors and material types are ideal for artists and hobbyists. Some printers allow for the use of flexible filaments, wood-filled composites, and even metal-infused materials, which can add a unique finish to your creations. For intricate designs and smooth finishes, a printer with a high resolution and the ability to print in multiple colors or materials simultaneously can be beneficial.

Types of 3D Printers

Understanding different 3D printing technologies is key to selecting the right printer.

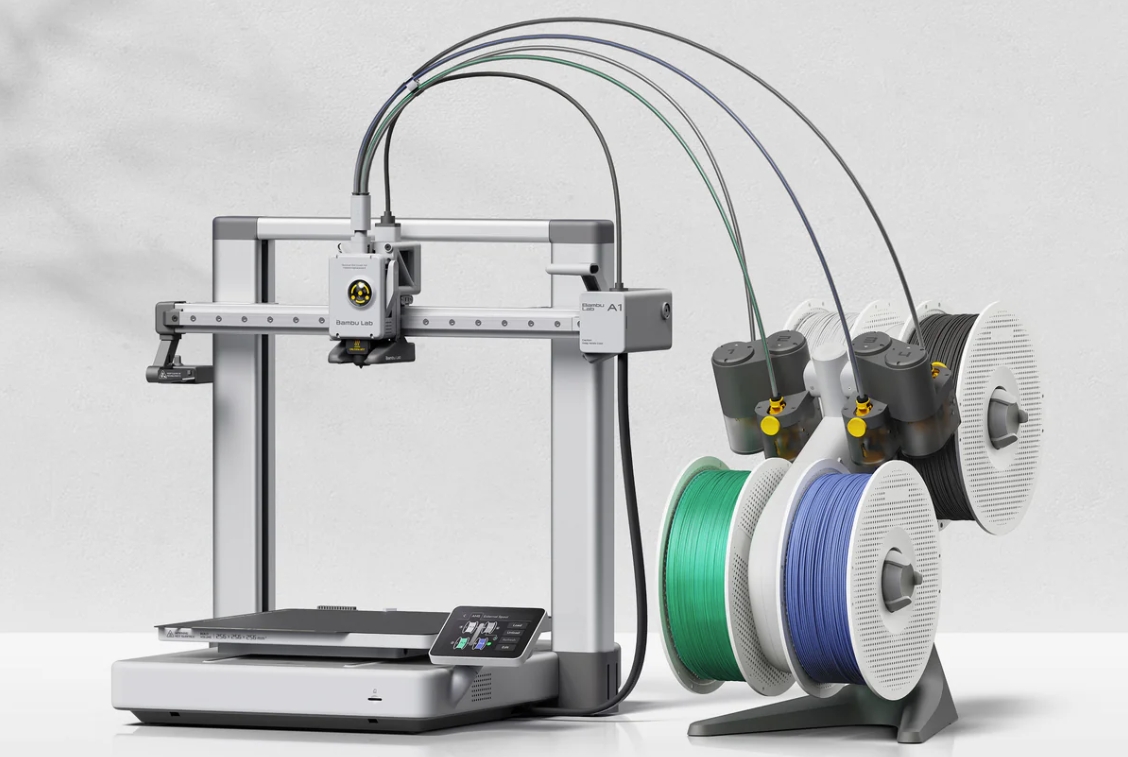

● FDM Printers

FDM is the most widely used form of 3D printing at the consumer level. FD 3D printers work by melting and extruding thermoplastic filament, which a print nozzle deposits layer by layer in the build area.

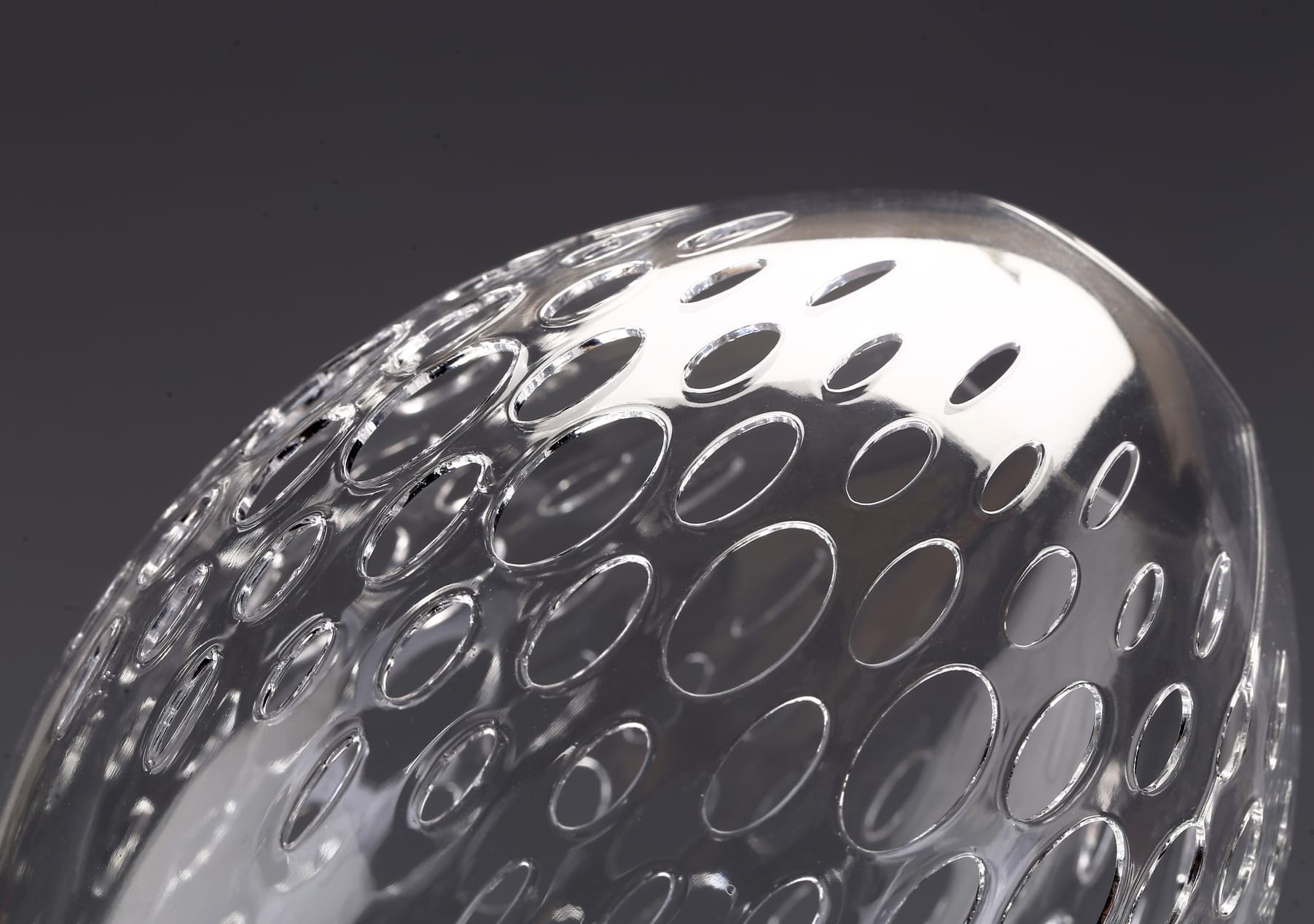

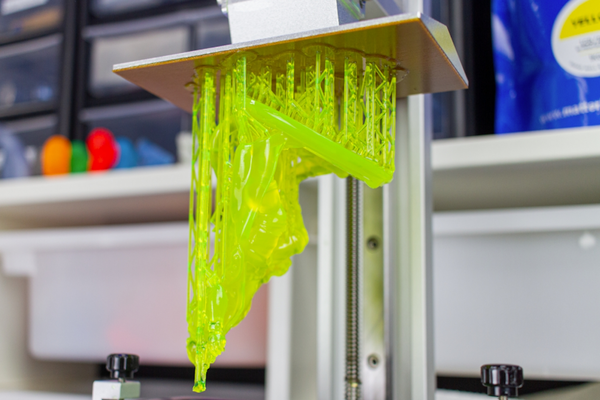

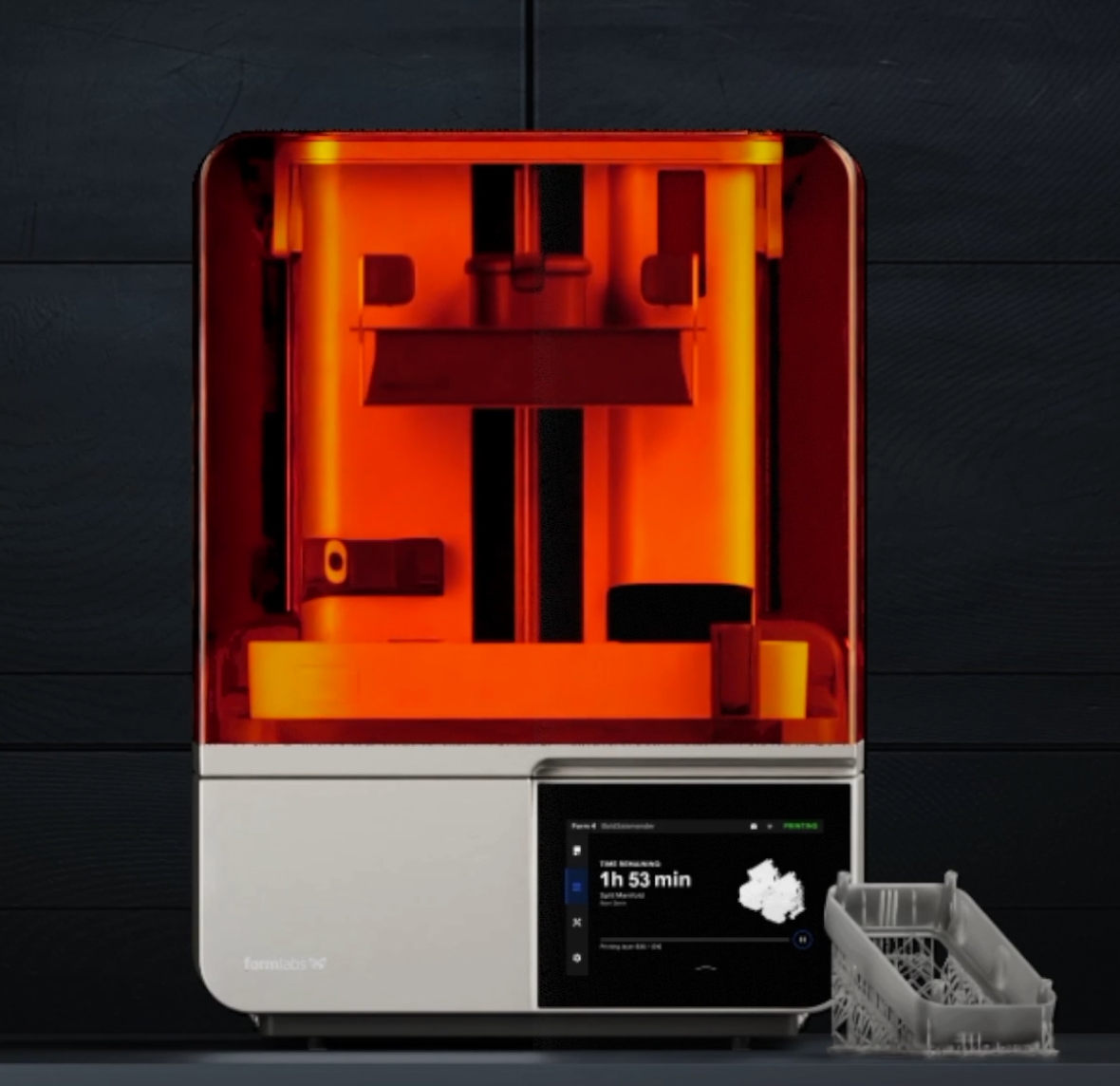

● SLA Printers

SLA 3D printers use an ultraviolet laser to cure liquid resin into hardened plastic in a process called photopolymerization, delivering high-resolution prints with excellent detail.

● DLP Printers

DLP printers also use photopolymerization, but instead of a laser, they use a digital projector to flash a single image of each layer across the entire platform, making it faster than SLA in some cases.

● SLS Printers

SLS doesn’t require support structures as SLS 3D printers use a laser to sinter powdered material, typically nylon, to form solid structures. This method is great for complex geometries and strong, functional parts.

● MJF Printers

Developed by HP, MJF 3D Printers use an inkjet array to apply fusing agents to a bed of nylon powder, which is then fused by heating elements. It’s known for its speed and ability to produce strong, detailed parts.

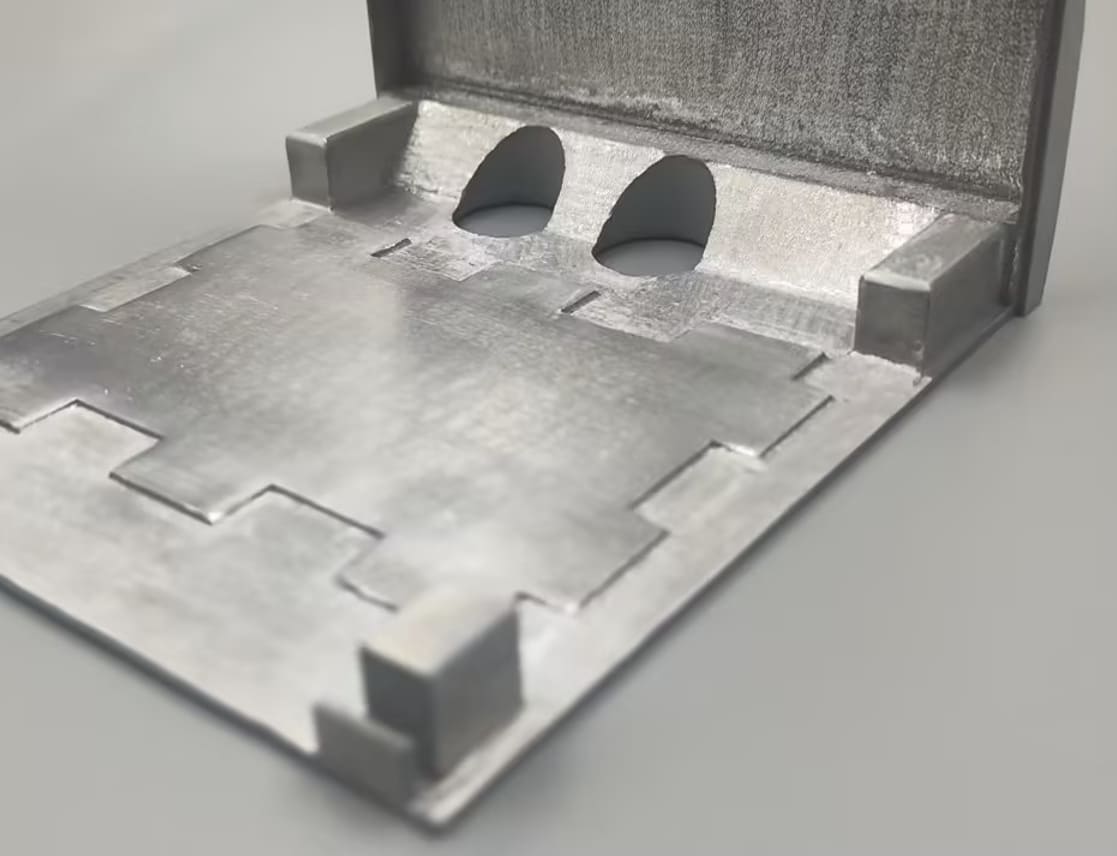

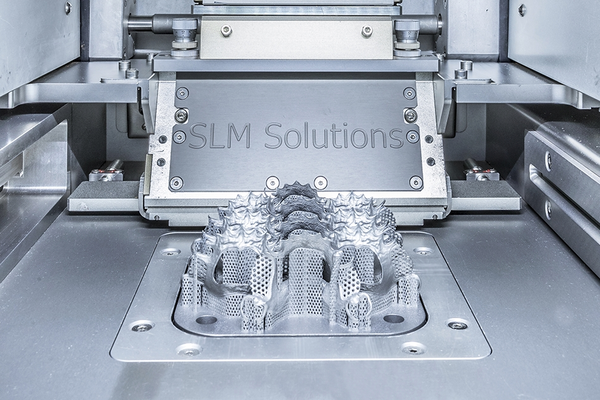

● SLM Printers

SLM is similar to SLS, but it fully melts the metal powder instead of just sintering it, resulting in very strong metal parts. It’s commonly used in the aerospace and automotive industries.

● Binder Jetting Printers

This technology spreads a thin layer of powder (metal, sand, or ceramic) and then selectively deposits a liquid binding agent in the cross-section of the part, layer by layer. It’s often used for full-color prototypes and large parts.

● PolyJet Printers

PolyJet printers work by jetting layers of curable liquid photopolymer onto a build tray. It can print in multiple materials and colors, offering incredible detail, precision, and a smooth surface finish.

Image Source: Bambu Lab

3D Printing Materials Compatibility

Each printing technology is compatible with specific materials, which in turn affects the properties of the final print. Understanding material compatibility is essential when choosing a 3D printer.

FDM Materials

FDM printers are known for their compatibility with a broad range of thermoplastic filaments, such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and TPU (Thermoplastic Polyurethane).

SLA and DLP Materials

SLA and DLP printers use photopolymer resins that harden upon exposure to UV light, such as standard resins, tough resins, flexible resins, and clear resins.

SLS and MJF Materials

SLS and MJF printers are known for their ability to print with powdered materials, including nylon (Polyamide), TPU powders, alumide, etc.

SLM Materials

SLM printers are specialized for metals and can work with a variety of metal powders, such as stainless steel, titanium, aluminum, etc.

Binder Jetting and PolyJet Materials

Binder Jetting can use a range of powders, including metal powders, sand, and ceramic.

PolyJet printers can print with multiple materials simultaneously, such as rigid and flexible photopolymers and full-color materials.

Image Source: MatterHackers

Budget

Initial Investment

1. Entry-Level Printers: Starting at around $200, these printers are suitable for beginners and offer basic functionality, ideal for small, non-complex items.

2. Mid-Range Printers: Ranging from $1,000 to $5,000, these offer better build quality, reliability, and finer resolution, suitable for serious hobbyists or small businesses.

3. Professional Printers: Prices can soar above $10,000, providing exceptional precision, material versatility, and larger build volumes for professional-grade prototypes and products.

Operating Costs

1. Material Expenses: The cost of filaments or resins can add up, especially if you’re printing frequently or in large volumes. Bulk purchases or generic brands can offer savings.

2. Maintenance and Repairs: Regular maintenance is crucial for printer longevity. Factor in the cost of replacement parts and potential professional servicing.

3. Electricity Consumption: While not a major expense, the energy requirements of your printer should be considered, particularly for models that need to run for long hours.

Software and Upgrades

1. Slicing Software: Some printers come with proprietary software, while others may require purchasing third-party applications, which can range from free to several hundred dollars.

2. Hardware Upgrades: To improve performance or maintain compatibility with new materials, you might need to invest in hardware upgrades like new nozzles or heating elements.

Post-Processing Equipment

1. Tools and Supplies: Depending on the complexity of your projects, you may need to invest in sanding tools, paints, or other finishing supplies.

2. Safety Equipment: Proper ventilation, gloves, and eye protection are essential for handling certain materials and post-processing tasks.

Hidden Costs

1. Time Investment: Your time is valuable. Consider the time you’ll spend on designing, printing, and post-processing, especially if 3D printing is part of your business.

2. Learning Curve: There may be courses or training you’ll want to take to master 3D printing techniques, which can also be a part of your budget.

Formlabs Latest Resin 3D Printer 4B: Packages Starting at $4,499

Image Source: Formlabs

3D Printer Efficiency

FDM Print Speed

FDM printers are generally the slowest due to the nature of the extrusion process. However, they offer a good balance between speed and detail for everyday printing tasks. Newer models are enhancing their speed without compromising the print quality.

SLA and DLP Print Speed

SLA printers, while precise, can be slower because the laser has to trace each layer. DLP printers can be faster as they cure a whole layer at once, but the speed also depends on the complexity of the print and the resin’s curing time.

SLS and MJF Print Speed

SLS and MJF printers are faster than FDM and SLA/DLP printers because they don’t require support structures and can sinter a layer of powder in one pass. MJF is particularly known for its rapid production capabilities.

SLM Print Speed

SLM printers are similar in speed to SLS printers but can be slower due to the high energy required to melt metal powders fully. The trade-off is the production of incredibly strong metal parts.

Binder Jetting Print Speed

Binder Jetting is known for its speed, especially when printing large parts or full-color prototypes, as it quickly deposits binding agents across each layer of powder.

PolyJet Print Speed

PolyJet printers are relatively fast and can print multiple materials simultaneously. However, the speed can vary depending on the complexity and the number of materials used.

Print Size

Understanding Build Volume

Build volume refers to the maximum physical space in which a 3D printer can fabricate an object. It is usually measured in length, width, and height (X, Y, and Z).

Desktop Printers

Most desktop 3D printers have a modest build volume, suitable for small to medium-sized prints. They are ideal for hobbyist projects and eucational purposes.

Professional and Industrial Printers

Professional and industrial 3D printers offer larger build volumes and are capable of printing functional parts, full-scale prototypes, end-use parts, tools and large art pieces.

Print Size by Technology

1. FDM printers typically offer a wide range of build volumes, from small desktop models to large-format printers.

2. SLA and DLP printers generally have smaller build volumes, prioritizing detail oversize.

3. SLS, MJF, and SLM printers can vary, with some industrial machines offering substantial build volumes for larger, functional parts.

4. Binder Jetting and PolyJet technologies are available in various build sizes, with some machines capable of printing large, complex parts or multiple smaller parts in a single batch.

3D Printer Resolution

FDM Resolution

FDM printers generally have a layer height ranging from 50 to 300 microns. While they may not achieve the same level of detail as other technologies, they are continually improving and can produce very satisfactory results for a wide range of applications.

SLA and DLP Resolution

SLA and DLP printers can achieve much finer resolutions, with layer heights as low as 25 microns. They excel at producing prints with smooth surfaces and intricate details, making them ideal for applications requiring high precision.

SLS and MJF Resolution

SLS and MJF printers typically have a resolution of around 100 microns for layer height. They are well-suited for functional parts that require good strength and precision but don’t need the ultra-fine detail of SLA or DLP.

SLM Resolution

SLM printers, used for metal printing, can also achieve layer heights of 20 to 100 microns. The resolution is sufficient for producing strong, functional metal parts with a good level of detail.

Binder Jetting and PolyJet Resolution

Binder Jetting can vary in resolution, but it’s often used for larger parts where ultra-fine detail is less critical. PolyJet printers, on the other hand, offer very high resolutions comparable to SLA and DLP, capable of printing multiple materials with intricate details and smooth surfaces.

Precision

Factors Affecting Precision

● Mechanical Stability: The rigidity of the printer’s frame and the quality of its components can affect precision.

● Calibration: Properly calibrated printers are essential for precise prints, as even minor deviations can lead to inaccuracies.

● Environmental Conditions: Temperature fluctuations and vibrations can impact print precision.

Precision Across Printing Technologies

1. FDM printers have made significant strides in precision, but they may still face challenges with warping or shrinkage, especially when printing with materials like ABS.

2. SLA and DLP printers offer high precision due to the fine control over the laser or light source, making them suitable for applications requiring tight tolerances.

3. SLS, MJF, and SLM printers are known for their precision in creating functional parts, as the powder-based process minimizes issues like warping.

4. Binder Jetting offers good precision, especially for large parts or when full-color and material properties are more critical than dimensional accuracy.

5. PolyJet printers excel in precision, capable of printing intricate details and complex geometries with high accuracy.

Ease to Use

Manufacturers are placing a greater emphasis on making 3D printers more accessible and user-friendly. Ease of use can significantly impact productivity, learning curve, and overall satisfaction.

Intuitive Design

A well-designed user interface (UI) that is intuitive and straightforward can make all the difference. Look for printers with:

● Clear Control Panels: Touchscreens with logical menus and prompts.

● User-Friendly Software: Slicing software that is easy to navigate and customize.

Setup and Calibration

● Auto-Calibration Features: Printers with automatic bed leveling and calibration reduce the time and expertise required to get started.

● Out-of-the-Box Functionality: Printers that come fully assembled or with clear instructions can simplify the initial setup process.

Reliability

● Consistent Performance: Printers that can repeatedly produce quality prints without constant adjustments offer a more user-friendly experience.

● Low Maintenance: Printers designed with fewer parts that wear out or require replacement can save time and hassle.

Support and Community

● Manufacturer Support: Good customer service and technical support can greatly enhance the user experience.

● Active User Communities: A robust online community for sharing tips, troubleshooting, and advice can be invaluable, especially for beginners.

Safety Features

● Enclosed Build Chambers: These can provide a safer printing environment by containing moving parts and high temperatures.

● Filament Detection: Printers that can detect filament runouts or jams can prevent failed prints and save resources.

Training and Resources

● Comprehensive Manuals: Detailed documentation and tutorials can help users understand their printer and its capabilities.

● Online Tutorials: Video guides and FAQs can be helpful for visual learners and troubleshooting specific issues.

Maintenance

Maintaining a 3D printer is crucial for ensuring its longevity, reliability, and the quality of prints it produces. Regular maintenance can prevent many common issues that might otherwise lead to downtime or the need for repairs.

Daily and Weekly Checks

1. Extruder: Check for any signs of clogging or filament residue that could affect print quality.

2. Print Bed: Clean the print bed after each use to remove any leftover material and ensure good adhesion for the next print.

3. Belts and Pulleys: Inspect for proper tension and alignment to prevent layer shifting or inaccuracies.

Monthly and Quarterly Tasks

1. Lubrication: Apply lubricant to the printer’s moving parts, such as rods and bearings, to ensure smooth operation.

2. Firmware Updates: Keep the printer’s firmware up to date to benefit from the latest improvements and bug fixes.

3. Nozzle Check: Inspect and clean the nozzle to prevent under-extrusion or blockages.

Long-Term Care

1. Calibration: Re-calibrate the printer periodically to maintain accuracy, especially after moving the printer or replacing parts.

2. Part Replacements: Be prepared to replace consumable parts like the nozzle, build plate surface, or belts as they wear out over time.

3. Electronics: Check the wiring and electronics for any signs of wear or damage that could lead to failures.

Record Keeping

Maintenance Log: Keep a log of all maintenance activities, part replacements, and any issues encountered. It can help diagnose problems and track the printer’s health over time.

Troubleshooting

1. Common Issues: Learn to identify and troubleshoot common issues such as warping, stringing, or poor adhesion.

2. Support Resources: Utilize manufacturer support, online forums, and community resources for troubleshooting help.

Professional Servicing

Annual Checkup: Consider having a professional service checkup annually, especially for high-end or heavily used printers.

Find More Related Resources

COMMENTS

- Be the first to share your thoughts!